OVERVIEW

At present, mechanical means are widely used at home and abroad to achieve modulation and demodulation to generate ultra-low frequency signals. However, this method has many inherent defects: the generated sinusoidal waveform deviates from the standard, resulting in considerable measurement errors; the high-voltage part is prone to spark discharge, which not only affects the stability of the equipment operation but also poses a safety hazard; the equipment is relatively bulky as a whole, which is not conducive to handling and operation; in addition, the second and fourth quadrants of the sine wave need to be discharged and shaped with the help of high-power high-voltage resistors, which significantly increases the overall power consumption of the equipment.

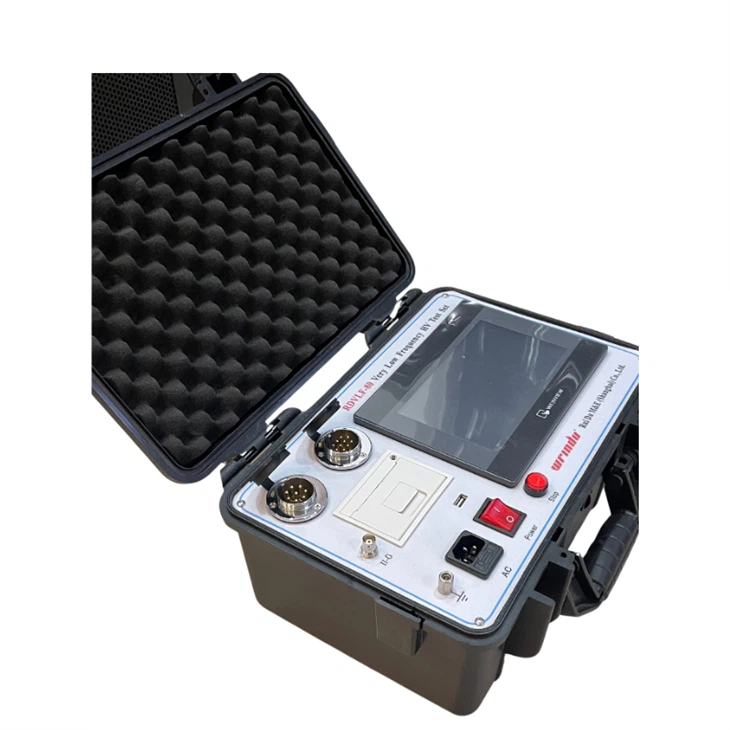

In contrast, this VLF hipot tester successfully overcomes the above disadvantages. It integrates modern advanced digital frequency conversion technology, uses microcomputers for intelligent control, and realizes fully automated operation of boosting, bucking, measurement, and protection. Automatic boosting also supports timely manual intervention, which is flexible and practical. Thanks to the fully electronic design concept, the product size is significantly reduced, the weight is greatly reduced, and it is easy to carry and install. The VLF hipot tester is equipped with a large-screen LCD, and various parameters and test statuses are displayed clearly and intuitively, significantly improving the user’s operating experience. At the same time, the instrument has a built-in thermal printer, which can print test reports instantly at the test site, facilitating data retention and subsequent analysis.

CHARACTERISTIC

- 1. The current and voltage data are directly sampled from the high-voltage side to ensure accuracy and reliability.

- 2. With the overvoltage protection function, the instrument will quickly shut down for protection when the output voltage exceeds the set value and the response time is less than 20 milliseconds.

- 3. The VLF hipot tester is equipped with overcurrent protection. With a dual high- and low-voltage protection design, the high-voltage side can be accurately shut down according to the set value, and the low-voltage side will automatically shut down for security when the current exceeds the rated value with an action time of less than 20 milliseconds.

- 4. The high-voltage output protection resistor is built into the booster; no external protection resistor is required.

- 5. Through high and low voltage closed-loop negative feedback control, the output is stable without capacitance rise effect.

For more information about withstand voltage testing equipment, please click More.

To request the latest quotes, please click Contact Us.

FAQ

Q: What is the difference between VLF and hipot?

A: VLF (Very Low Frequency) refers to the frequency range (0.1 Hz to 100 Hz), and it’s often used for testing electrical cables. Hipot (High Potential) testing involves applying a higher-than-normal voltage to check for insulation breakdown. VLF hipot testing combines both, using low-frequency signals at high potentials for comprehensive electrical testing.

Q: What is the VLF hipot test method?

A: VLF hipot testing combines low-frequency (0.1-100 Hz) and high-potential testing. Apply VLF voltage to the device, monitor for breakdown, perform hipot testing, analyze results, and generate a detailed report. This method effectively assesses insulation integrity in high-voltage equipment.

Q: What is the voltage for VLF testing?

A: VLF (Very Low Frequency) testing typically involves applying voltages in the range of 0.1 Hz to 100 Hz, with test voltages ranging from several kilovolts to tens of kilovolts. The specific voltage depends on the equipment or cables being tested and should adhere to relevant standards and guidelines.

Q: What are the advantages of VLF testing?

A: VLF testing excels with enhanced sensitivity to insulation defects, reduced cable stress, improved safety, realistic simulation of operating conditions, effective issue detection, compliance with standards, cost-effectiveness, and shorter testing times compared to DC testing.