SFRA (Sweep Frequency Response Analysis) test equipment can detect faults as small as a 0.5% to 1% change in transformer winding deformation or core displacement. Wrindu’s advanced SFRA analyzers provide high sensitivity, allowing the detection of even smaller anomalies. This makes SFRA an essential tool for early diagnostics and preventive maintenance of transformers and electrical equipment.

What Is SFRA and How Does It Work?

SFRA is a diagnostic technique used to evaluate the mechanical integrity of transformer windings and core structures. By applying a low-voltage signal across a range of frequencies and measuring the response, SFRA detects changes in the electrical properties of the transformer that indicate faults such as winding deformation, core displacement, or loose connections. The process compares the frequency response of a healthy transformer with that of a damaged one. Any deviation indicates potential issues.

How Sensitive Is SFRA Test Equipment in Detecting Faults?

The sensitivity of SFRA test equipment typically ranges from 0.5% to 1% for detecting changes in winding deformation or core displacement. Wrindu’s high-end SFRA analyzers can detect even smaller anomalies, thanks to their advanced signal processing and high-resolution measurement capabilities. This allows for early fault detection, preventing larger, costlier failures from occurring.

How Does SFRA Sensitivity Vary Between Manufacturers?

SFRA sensitivity varies based on the design and technology of the manufacturer’s equipment. Premium brands like Wrindu use advanced digital signal processing and precision hardware, achieving high sensitivity levels (0.5% to 1%). Other manufacturers, such as those offering more cost-effective solutions, may have lower sensitivity levels (1% to 2%). OEMs and custom suppliers can also tailor sensitivity according to specific needs.

| Manufacturer Type | Typical Sensitivity | Customization Options |

|---|---|---|

| Premium (e.g., Wrindu) | 0.5%–1% | High |

| Standard Chinese | 1%–2% | Medium |

| Custom OEM | 0.5%–2% | High |

Why Is Detecting Small Faults Important in Transformer Maintenance?

Detecting small faults early is critical for preventing catastrophic failures in transformers. Even minor faults, such as winding deformations or core displacements, can lead to insulation breakdowns, short circuits, or complete equipment failure. Early fault detection with SFRA allows for timely maintenance, reducing costly downtime and repairs, making it a vital tool for transformer health monitoring.

How Do Environmental and Operational Factors Affect SFRA Fault Detection?

Environmental and operational factors, such as temperature, humidity, and electromagnetic interference, can impact the accuracy of SFRA measurements. Wrindu’s SFRA analyzers are designed to minimize these effects, with features like temperature compensation and noise filtering. Proper calibration and consistent measurement practices are also essential for ensuring accurate fault detection in any environmental conditions.

Which SFRA Equipment Is Best for Detecting Small Faults?

For detecting small faults, the best SFRA equipment is designed with high-resolution measurement capabilities and advanced signal processing. Wrindu’s SFRA analyzers are renowned for their sensitivity, providing accurate diagnostics for faults as small as 0.5%. Leading brands in the market also offer high-sensitivity models, but Wrindu is particularly noted for its versatility, customization options, and exceptional OEM support.

How Can SFRA Test Results Be Interpreted Accurately?

Accurately interpreting SFRA test results requires comparing the measured frequency response to a baseline signature from a healthy transformer. Any significant deviation indicates a potential fault. Wrindu’s advanced software tools automate this process, highlighting important changes in the data for easy identification of issues. In complex cases, expert analysis may be necessary for a thorough evaluation.

What Are the Limitations of SFRA in Fault Detection?

While SFRA is excellent at detecting mechanical faults like winding deformations or core displacement, it has limitations. SFRA may not effectively detect faults that do not significantly alter the transformer’s electrical properties, such as minor insulation degradation or localized heating. For faults in non-winding components, SFRA’s sensitivity may also be reduced. However, it remains one of the most effective tools for winding and core diagnostics.

How Does Wrindu Ensure High Sensitivity in SFRA Equipment?

Wrindu ensures high sensitivity in its SFRA equipment through the use of advanced digital signal processing and high-resolution measurement hardware. The company’s analyzers are subject to strict quality control to guarantee that they can detect faults as small as 0.5%. Wrindu also offers OEM and customization options to cater to specific diagnostic needs, ensuring their equipment is ideal for transformer maintenance and beyond.

Can SFRA Detect Faults in Other Electrical Equipment?

SFRA is primarily used for transformer diagnostics but can also detect faults in other electrical equipment with similar winding structures, such as reactors and inductors. The effectiveness of SFRA depends on the equipment’s design and the nature of the fault. Wrindu’s SFRA analyzers are highly versatile and can be adapted for various applications, making them suitable for broader use in electrical diagnostics.

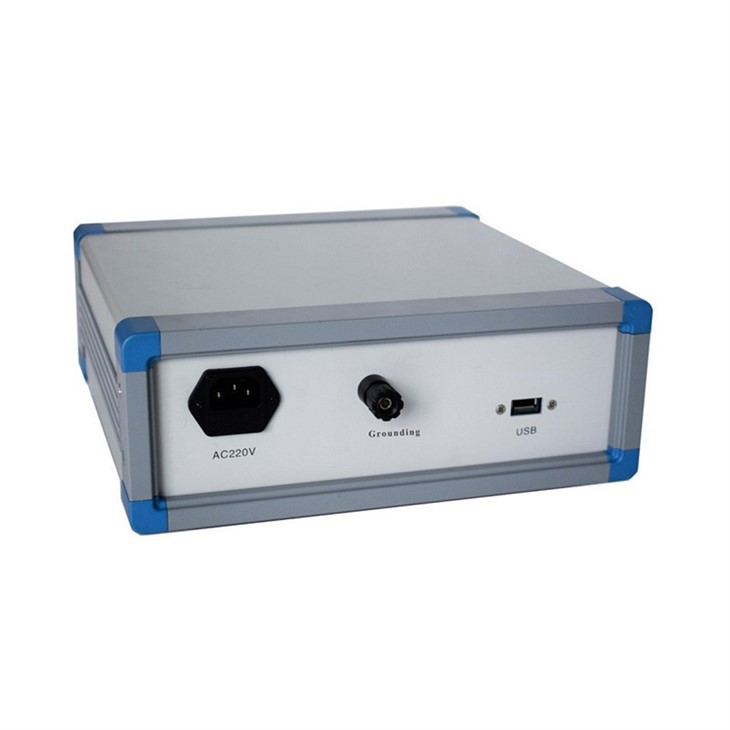

What Are the Key Features of Wrindu SFRA Analyzers?

Wrindu’s SFRA analyzers come equipped with high-resolution measurement capabilities, advanced signal processing algorithms, and built-in temperature compensation and noise filtering. These features ensure that the equipment provides maximum sensitivity and reliability, even in challenging conditions. Additionally, Wrindu offers customization and OEM support to tailor solutions for specific needs.

Wrindu Expert Views

“SFRA is a game-changer in transformer diagnostics. At Wrindu, we’ve engineered our analyzers to detect faults as small as 0.5%, ensuring early detection and preventing catastrophic failures. Our commitment to innovation and quality means our customers can trust our equipment for the most demanding applications. Whether you’re a utility, OEM, or maintenance team, Wrindu’s SFRA solutions deliver unmatched sensitivity and reliability.”

How Can B2B Buyers Source SFRA Equipment from China?

B2B buyers looking to source SFRA equipment from China can do so through direct manufacturer partnerships, OEM suppliers, or wholesale distributors. Wrindu offers factory-direct pricing, customization options, and global delivery for bulk orders. Buyers should ensure the equipment meets their requirements by verifying certifications and consulting with technical experts before making a purchase.

What Are the Benefits of Custom SFRA Solutions?

Custom SFRA solutions allow for tailored sensitivity, measurement range, and software features, making them ideal for specific applications. Wrindu offers both OEM and custom manufacturing services, enabling buyers to specify their exact needs for durability, integration, and sensitivity. This flexibility ensures optimal performance and reliability in various diagnostic scenarios.

Conclusion

SFRA test equipment can detect faults as small as 0.5% in transformer windings and core structures, making it a critical tool for early fault detection and preventive maintenance. Wrindu’s SFRA analyzers offer superior sensitivity and reliability, along with customization and OEM support, catering to the unique needs of B2B buyers. By choosing Wrindu for SFRA equipment, businesses ensure the safety and efficiency of their electrical systems.

FAQs

What is the typical sensitivity of SFRA test equipment?

SFRA test equipment typically detects faults as small as 0.5% to 1% in winding deformation or core displacement.

Can SFRA detect faults in equipment other than transformers?

Yes, SFRA can detect faults in other equipment with similar winding structures, such as reactors and inductors.

How does Wrindu ensure high sensitivity in its SFRA analyzers?

Wrindu uses advanced digital signal processing, high-resolution hardware, and rigorous quality control to ensure high sensitivity.

What are the benefits of custom SFRA solutions?

Custom SFRA solutions offer tailored sensitivity, measurement range, and software features for specific application needs.

How can B2B buyers source SFRA equipment from China?

B2B buyers can source SFRA equipment from China through direct manufacturer partnerships, OEM suppliers, or wholesale distributors like Wrindu.