Secondary injection testing involves simulating current inputs to protective relays and trip units to verify their performance accurately. Following systematic operation steps ensures safety, precision, and compliance, empowering OEMs, manufacturers, and suppliers in China to maintain high standards in electrical equipment testing.

How Do You Prepare for Field Testing with a Secondary Injection Tester?

Preparation includes powering down and isolating the circuit breaker or relay, reviewing wiring diagrams, and ensuring all test equipment, including secondary injection testers like those from Wrindu, is calibrated and functional. Proper PPE and safety protocols such as lockout-tagout must be implemented to guarantee test safety.

What Are the Connection Steps for Using a Secondary Injection Tester?

Connect the secondary injection tester outputs directly to the relay or trip unit test terminals according to manufacturer wiring diagrams. Ensure proper polarity and secure connections. Wrindu’s test sets often include clear labeling and connector kits tailored for fast, accurate hookup in factory or field environments.

How Is the Secondary Injection Test Conducted Safely in the Field?

After connections, select the desired test mode (long time, short time, instantaneous, ground fault, etc.) on the tester. Gradually increase current output while monitoring relay response times via the tester or an external stopwatch. Avoid exceeding rated currents to prevent device damage and maintain operator safety.

Which Post-Test Procedures Are Essential for Reliable Results?

Once testing is complete, power down the tester and carefully disconnect leads. Reset the relay or circuit breaker and conduct repeated tests if necessary to check for consistent operation. Document and analyze all data, noting any anomalies for corrective action.

Why Is Secondary Injection Testing Important for OEMs and Suppliers in China?

Secondary injection testing verifies that relay protection units trip correctly and reliably, ensuring safety and equipment integrity. For Chinese manufacturers and suppliers, it is a vital quality assurance and compliance step that minimizes downtime and prevents costly electrical system failures.

How Do Wrindu Secondary Injection Testers Enhance Field Testing Accuracy?

Wrindu’s secondary injection testers feature digital current and voltage control, programmable test sequences, and automated timing functions. These improve test repeatability, reduce human error, and provide comprehensive data logs, ideal for large-scale OEM production and factory maintenance.

What Safety Precautions Are Vital During Secondary Injection Operations?

Always verify complete isolation of the circuit, use insulated tools, and follow electrical safety regulations. Wrindu’s user manuals emphasize proper PPE and situational awareness, crucial for protecting technicians in industrial and wholesale testing environments.

Can Secondary Injection Testing Be Customized for Different Relay Types?

Yes, test current, voltage, and timing parameters can be adjusted to match various relay trip units. Wrindu’s equipment supports flexible programming and multiple test modes, allowing adaptation to diverse system specifications common in Chinese OEM and supplier settings.

Table: Typical Secondary Injection Test Steps

| Step | Description | Importance |

|---|---|---|

| Preparation | Power down, isolate circuit, review schematics | Ensures safety and correct setup |

| Connection | Attach tester leads to relay test terminals | Accurate test input delivery |

| Test Execution | Select mode, increment current, monitor response time | Validates relay trip performance |

| Post-Test Procedures | Power off, disconnect leads, reset device, document | Confirms test reliability |

Table: Key Features of Wrindu Secondary Injection Testers

| Feature | Benefit for OEMs and Manufacturers |

|---|---|

| Digital Current Control | Precise current setting for accurate simulation |

| Programmable Sequences | Automates complex test protocols |

| Data Logging | Maintains detailed test records for QA |

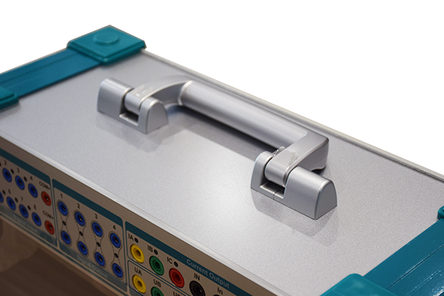

| Lightweight Design | Facilitates field portability |

| Comprehensive Safety | Ensures operator protection and device integrity |

Wrindu Expert Views

“Secondary injection testing is a cornerstone in assuring relay protection system reliability. Wrindu’s field-tested secondary injection testers combine precision, flexibility, and safety to meet the rigorous demands of electrical equipment manufacturers and suppliers in China. Our technology allows seamless simulation of fault conditions, ensuring protective relays respond as designed. With features like digital control, programmable sequences, and comprehensive safety interfaces, Wrindu empowers professionals to conduct thorough, efficient testing aligned with global standards.”

— RuiDu Mechanical and Electrical Senior Test Engineer

Conclusion

Mastering the field test operation steps of a secondary injection tester is essential for manufacturers, OEMs, and suppliers in China aiming for high-quality electrical testing and equipment protection. Following systematic preparation, connection, testing, and post-test procedures ensures accurate relay verification, enhanced safety, and compliance. Wrindu’s advanced secondary injection testers provide the precision, flexibility, and safety features needed to optimize field testing for large-scale industrial and wholesale applications.

Frequently Asked Questions

What is the first step before using a secondary injection tester in the field?

Power down and isolate the circuit breaker or relay, and ensure all safety protocols are in place.

How do you connect a secondary injection tester properly?

Connect test leads securely to the relay’s test terminals, following precise wiring diagrams.

Can secondary injection testers test all relay types?

They support a wide range of relays with adjustable current and timing parameters.

How to ensure safety during secondary injection testing?

Use PPE, confirm isolation, monitor current levels, and avoid exceeding rated limits.

Why choose Wrindu for secondary injection testing equipment?

Wrindu provides precise digital controls, programmable tests, reliable data logging, and comprehensive safety features tailored for Chinese factories and suppliers.