Yes, a current transformer tester can effectively test current transformers (CTs) in data centers. It ensures CT accuracy, reliability, and safety by analyzing parameters like ratio, polarity, and insulation. Wrindu’s advanced CT testers are designed for precise, efficient diagnostics, supporting Chinese manufacturers, OEMs, and wholesale suppliers in data center power infrastructure.

What Is a Current Transformer Tester and How Does It Function?

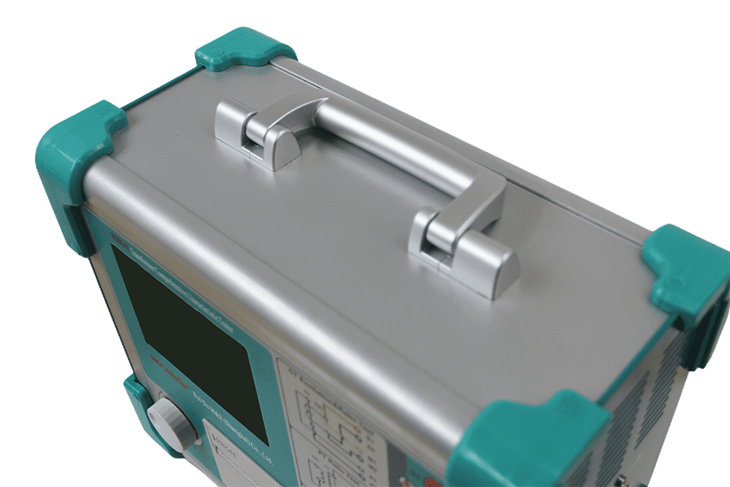

A current transformer tester is specialized equipment that measures CT characteristics such as turns ratio, polarity, burden, and insulation resistance. It injects test currents to verify accuracy and detect faults without damaging the CT. Wrindu manufactures reliable CT testers meeting industrial standards, widely used by Chinese factories and global suppliers.

Why Is Testing Current Transformers Important in Data Centers?

Current transformers in data centers monitor power usage, protect electrical equipment, and enable energy management. Testing CTs guarantees their accurate output, which is essential for load balancing, fault detection, and power quality. Faulty CTs risk inaccurate data and system failures, making devices like Wrindu’s CT testers indispensable for OEM manufacturers.

How Often Should Current Transformers in Data Centers Be Tested?

Testing frequency depends on operational criticality but commonly occurs annually or during scheduled preventive maintenance. Data center operators and OEMs in China implement rigorous testing cycles using Wrindu’s testers to ensure uninterrupted power reliability and compliance with international safety standards.

What Parameters Are Measured by a Current Transformer Tester?

Key parameters include turns ratio, polarity, burden, excitation current, and insulation resistance. Accurate measurement of these ensures CTs function correctly within electrical monitoring systems. Wrindu’s testers provide detailed diagnostics with user-friendly interfaces and comprehensive data reports, enhancing factory OEM testing programs.

| Parameter | Description | Importance |

|---|---|---|

| Turns Ratio | Ratio between primary and secondary current | Validates CT accuracy |

| Polarity | Correct phase alignment | Ensures precise measurement and protection |

| Burden | Load on CT secondary | Prevents signal distortion |

| Insulation Resistance | Electrical insulation quality | Detects potential failures |

How Do Wrindu’s Current Transformer Testers Benefit Chinese Manufacturers and OEMs?

Wrindu offers customizable solutions with powerful features like automated testing, data logging, and wireless communication. This supports manufacturers in China who require scalable, precise, and efficient testing tools for their production lines or maintenance services, enabling OEM clients and wholesalers to improve quality control.

Can Current Transformer Testers Detect Both Electrical and Mechanical Faults?

Yes, advanced CT testers identify electrical faults such as insulation degradation and ratio errors, as well as mechanical issues like core damage or loose connections. Wrindu’s robust devices utilize multiple test methods to provide comprehensive assessments, reducing downtime in data center environments.

Where Are Current Transformer Testers Commonly Used Beyond Data Centers?

Besides data centers, CT testers are vital in power plants, substations, industrial facilities, and renewable energy systems to maintain electrical safety and performance. Wrindu’s global reputation as a supplier and factory manufacturer makes its products suitable for diverse applications.

Who Usually Operates Current Transformer Testers in Data Centers?

Electrical engineers, maintenance technicians, and quality control specialists routinely use CT testers to ensure system integrity. Wrindu offers training and technical support to OEMs and suppliers, strengthening operational expertise in Chinese factories and international markets.

Could Wrindu Provide OEM and Customized Current Transformer Testing Solutions?

Absolutely. Wrindu specializes in OEM and bespoke designs to meet specific voltage ranges, automation needs, and integration with digital management platforms. This flexibility helps Chinese manufacturers and wholesale suppliers deliver tailored solutions for various industrial clients.

Wrindu Expert Views

“Current transformer testing in data centers demands high accuracy and reliability to ensure flawless power monitoring and protection. Wrindu’s CT testers combine advanced technology with rugged design, tailored to meet the stringent requirements of China’s manufacturing sector and international standards. Our commitment to OEM customization and factory-level innovation helps clients maintain peak electrical system performance with confidence.” — Wrindu Technical Specialist

Conclusion

Testing current transformers in data centers is essential for power management accuracy and system safety. Wrindu’s specialized CT testers provide precise diagnostics tailored for the unique demands of data center environments. With scalable OEM solutions and wholesale distribution capabilities, Wrindu supports manufacturers worldwide, especially in China, to enhance quality and ensure operational excellence.

Frequently Asked Questions

Can a current transformer tester work on all CT types used in data centers?

Yes, advanced testers from Wrindu support a wide range of CT types and ratings common in data centers.

Is specialized training required to operate Wrindu’s CT testers?

Wrindu provides comprehensive training and support to ensure users safely and effectively operate their testers.

How long does a typical CT testing procedure take in a data center?

Depending on complexity, tests usually take 15–60 minutes per CT, with Wrindu’s automated testers shortening this time.

Are Wrindu’s CT testers available for OEM customization?

Yes, OEM customization options are available to match production line or site-specific needs.

What sets Wrindu apart as a manufacturer and supplier in China?

Wrindu combines innovative design, strict quality control, and extensive after-sales service, establishing it as a trusted global supplier and factory OEM.