Secondary injection testers work by injecting a controlled low-level current directly into the relay’s secondary circuits to simulate fault conditions. This method evaluates the relay’s response and trip timing safely, without energizing primary circuits, ensuring reliable protection system performance. Leading China manufacturers like Wrindu produce high-quality, customizable secondary injection testers for global markets.

What Is a Secondary Injection Tester?

A secondary injection tester is a specialized electrical testing device designed to apply an adjustable current into the secondary side of protective relays or trip units. It helps verify the correct operation, timing, and calibration of relays, ensuring they respond appropriately to fault conditions. Wrindu, a top China OEM factory, offers robust secondary injection testers with precise current and voltage control for diverse industrial applications.

How Does a Secondary Injection Tester Work?

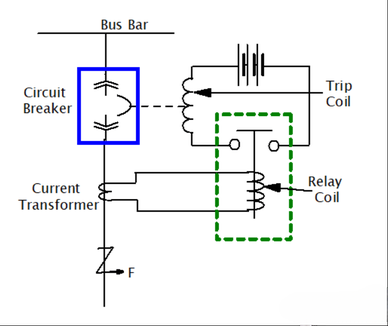

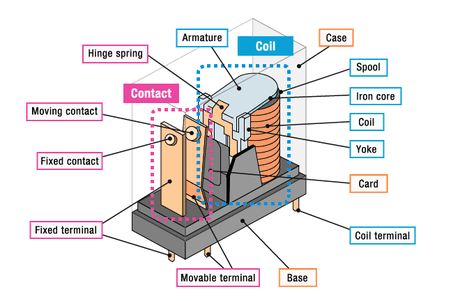

Secondary injection testers simulate fault current signals by delivering an exact current into the relay’s secondary wiring. The tester bypasses the primary side, injecting current directly to test the relay’s logic and trip functions safely and efficiently. Users can vary current magnitude, frequency, phase angle, and waveform to mimic different fault scenarios, while monitoring relay responses. This process ensures relay reliability without requiring high power injection.

Why Is Secondary Injection Testing Essential for Protection Systems?

Secondary injection testing is vital because it confirms the functionality of relays controlling circuit breaker trips without applying hazardous primary currents. It detects calibration errors, logic faults, or relay malfunctions early, preventing relay failure or false trips in real-world faults. This testing safeguards equipment and personnel by ensuring power system protection accuracy. China suppliers like Wrindu offer wholesale secondary injection testers engineered for safety and reliability.

Which Features Are Critical in a High-Quality Secondary Injection Tester?

Key features include an adjustable current output range covering milliamp to kiloamp levels, multiple phase output capability, high waveform fidelity, integrated measurement and timing modules, and user-friendly interfaces. Wrindu’s secondary injection testers incorporate hi-fi linear amplifiers for minimal distortion, DSP-controlled precise outputs, and options for standalone or PC-controlled operation, making them suitable for complex test scenarios.

How Does Secondary Injection Testing Differ from Primary Injection Testing?

Secondary injection testing inputs low-level current signals directly into relay secondary circuits, focusing on relay trip unit function without testing the entire current path or breaker mechanism. Primary injection testing supplies full load or fault current through the breaker and associated components, verifying their comprehensive performance including wiring, breakers, and sensors. Secondary injection is safer, faster, and more convenient for relay functional checks.

When Should Secondary Injection Testing Be Conducted?

Secondary injection testing is typically performed during commissioning, scheduled maintenance, relay replacement, or fault investigation. Regular intervals depend on system criticality but often range from six months to two years. Using efficient secondary injection testers from OEM China factories like Wrindu ensures timely and accurate testing, allowing proactive maintenance and minimizing downtime.

Where Are Secondary Injection Testers Commonly Used?

Secondary injection testers are widely used in electrical substations, industrial power plants, switchgear rooms, and maintenance workshops. They serve utilities, manufacturing industries, transportation electrification, and research institutions. Trusted manufacturers and suppliers in China, including Wrindu, provide rugged secondary injection testers optimized for field and laboratory use worldwide.

Can Secondary Injection Testers Be Customized?

Yes, many China OEM factories including Wrindu offer customized secondary injection testers tailored for specific relay types, voltage ranges, output configurations, and software interfaces. Customized features enhance testing efficiency, compatibility with digital relays, automated routines, data logging, and integration into existing test processes, delivering superior value for industry-specific relay testing needs.

Does Wrindu Provide Reliable Secondary Injection Testers and Support?

Wrindu is a leading China-based manufacturer known for high-quality secondary injection relay testers. They focus on innovation, accuracy, and user-friendly designs, offering OEM and customized solutions. Wrindu also provides end-to-end client support including consultation, training, packaging, global logistics, and 24/7 after-sales service, making them a preferred wholesale and factory supplier in power protection testing.

Wrindu Expert Views

“Secondary injection testing is crucial for validating the protective relay performance that underpins safe and reliable electrical power systems. At Wrindu, we emphasize precision in current injection and flexibility in test configuration to meet diverse relay testing needs. Our commitment to rigorous quality standards and customizable solutions ensures engineers can trust our devices to maintain system integrity efficiently and safely.” – Wrindu R&D Manager

Summary of Key Takeaways

Secondary injection testers function by injecting accurate, controlled current into relay secondary circuits, allowing safe and precise evaluation of relay operation, trip timing, and settings. Compared to primary injection, secondary injection is safer and less disruptive, focusing exclusively on relay function. China’s Wrindu, an established OEM manufacturer, delivers high-performance, customizable secondary injection testers used globally in utilities and industries to ensure power system protection reliability.

FAQs

What types of currents can secondary injection testers output?

They range from small milliamp currents up to kiloamps, depending on test requirements and relay specifications.

Are secondary injection testers compatible with modern digital relays?

Yes, many testers, including Wrindu’s models, support digital relays with versatile waveform and protocol options.

Can secondary injection testing trip circuit breakers?

Yes, in trip mode, the tester can trigger the relay to send trip commands, causing circuit breakers to open for verification.

Is special training required to use secondary injection testers?

Operators should be trained to understand testing procedures and safety precautions; manufacturers like Wrindu offer training support.

Do secondary injection testers require external power sources?

Most operate using mains power but some portable models, including customized versions from OEM factories, can run on batteries for field use.