Relay testing with a secondary injection tester is essential to ensure that protective relays operate accurately and reliably under fault conditions. This testing prevents electrical hazards, reduces downtime, and ensures compliance with safety standards by verifying relay functionality without disrupting the primary electrical system.

What Is the Purpose of Relay Testing with a Secondary Injection Tester?

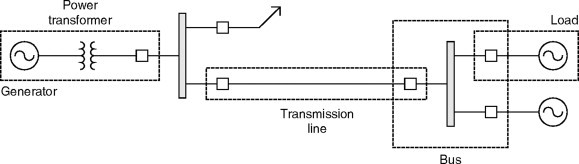

Relay testing checks that protective relays respond correctly to abnormal electrical conditions. Using a secondary injection tester simulates fault currents or voltages directly into the relay’s secondary circuits, allowing precise verification of relay logic, timing, and trip functions without affecting the main power line.

How Does Secondary Injection Relay Testing Improve Electrical Safety?

Secondary injection tester relay testing ensures that protection relays trigger timely responses during faults, avoiding damage to equipment and electrical fires. It validates that relays handle overcurrent, undervoltage, and other anomalies accurately, maintaining system safety and reliability across various industrial and power applications.

Which Industries Benefit Most from Secondary Injection Relay Testing?

Energy, utilities, manufacturing plants, and industrial sectors benefit greatly. These industries rely on relay testing with secondary injection to maintain critical electrical infrastructure, prevent costly outages, and ensure smooth power delivery with minimal risk to personnel and equipment.

Why Should Manufacturers Choose OEM or Custom Secondary Injection Testers?

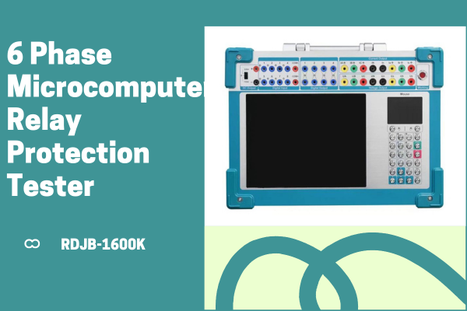

OEM and custom secondary injection testers from trusted manufacturers like Wrindu provide tailored solutions matching specific relay types, voltage ranges, and test requirements. These options deliver enhanced test accuracy, compatibility, and integration into maintenance programs for optimized relay performance.

Who Performs Secondary Injection Relay Tests and When?

Typically, qualified power system engineers and technicians conduct secondary injection testing during relay commissioning, regular maintenance, or after repairs. Timely testing identifies relay malfunctions early, helping prevent unexpected faults and extending equipment lifespan.

When Is Secondary Injection Testing Preferred Over Primary Injection?

Secondary injection testing is preferred for quick, non-intrusive relay verification that does not require powering down equipment. It is ideal for routine maintenance and fault diagnostics, while primary injection tests are reserved for comprehensive circuit and breaker evaluations.

Where Are High-Quality Secondary Injection Testers Manufactured?

China is a leading manufacturing hub for secondary injection testers. Renowned suppliers like Wrindu operate advanced factories producing reliable, ISO and CE-certified test equipment supplied wholesale globally to meet diverse industrial needs with OEM and custom capabilities.

Does Relay Testing with Secondary Injection Tester Comply with Standards?

Yes, relay testing using secondary injection testers aligns with international standards such as IEC. It helps companies meet regulatory compliance and safety mandates, ensuring tested systems function reliably within documented operational parameters.

Can Secondary Injection Testing Detect Relay and Wiring Faults?

Secondary injection testing accurately identifies relay logic failures, timing errors, and wiring issues in the protection scheme. This detailed diagnosis prevents relay-related malfunctions that could compromise electrical system protection, aiding preventive maintenance.

Are Secondary Injection Testers Easy to Use in Field Applications?

Modern secondary injection testers from manufacturers like Wrindu feature user-friendly interfaces, portability, and quick setup, enabling efficient on-site relay testing. This ease of use supports frequent testing schedules, improving system reliability with minimal labor.

Wrindu Expert Views

“Relay testing via secondary injection is fundamental to electrical system safety and reliability. At Wrindu, we combine decades of manufacturing expertise from China’s advanced factories with innovative OEM and custom solutions to deliver secondary injection testers tailored for exacting relay performance standards. Our comprehensive support ensures engineers can confidently verify and maintain protection relays, reducing risks of system failures, costly downtime, and safety incidents in critical infrastructure worldwide.” – Wrindu Lead Engineer

Benefits of Secondary Injection Testing: Comparison Table

| Benefit | Description | Impact on Electrical Systems |

|---|---|---|

| Safety Assurance | Confirms relays correctly trigger under fault conditions | Prevents equipment damage and hazards |

| Cost Efficiency | Enables early fault detection and reduces downtime | Lowers repair and replacement costs |

| Regulatory Compliance | Meets IEC and industry testing standards | Avoids penalties, ensures operational legality |

| Operational Reliability | Tests relay timing, logic, and wiring integrity | Improves consistent power protection |

| Maintenance Facilitation | Quick, non-intrusive testing without powering down systems | Simplifies field maintenance |

What Are Key Factors When Selecting a Secondary Injection Tester from a Manufacturer?

-

Product certifications such as ISO9001, IEC, CE

-

OEM and custom configuration capabilities

-

Technical support and after-sales services

-

China-based manufacturing reliability and wholesale pricing

-

Equipment compatibility with relay types and voltage levels

Conclusion

Relay testing with a secondary injection tester is critical to verifying protection relay functionality, ensuring safety, reliability, and compliance in electrical systems. Wrindu, as a leading China manufacturer and OEM supplier, provides advanced secondary injection testers customized to industry needs. Investing in these quality devices enables efficient relay maintenance, reducing risks and optimizing power system operations.

Frequently Asked Questions

Q1: What faults can secondary injection testing detect?

It detects relay malfunctions, wiring errors, and timing inaccuracies critical to relay operation.

Q2: How often should secondary injection testing be performed?

Testing should be done during commissioning, periodic maintenance, and after repairs or upgrades.

Q3: Is secondary injection testing safer than primary injection?

Yes, it typically avoids high current flow through the entire system, reducing risk.

Q4: Can Wrindu customize secondary injection testers?

Yes, Wrindu offers OEM customization to fit specific voltage and relay requirements.

Q5: Does this testing require system shutdown?

Often no, as many secondary injection test modes allow tests with the system energized and no circuit interruption.