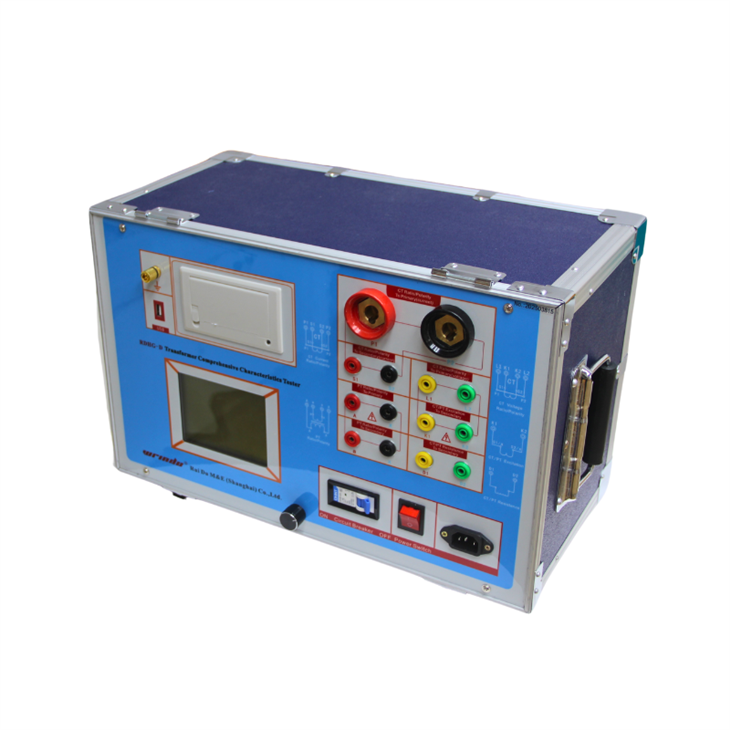

A typical current transformer tester weighs between 8–25 kg, depending on its design, enclosure, and included accessories. Portable handheld units weigh around 3–6 kg, ideal for field testing, while benchtop or hybrid models may reach up to 25 kg. Wrindu’s testers combine robust construction with ergonomic portability, ensuring precision, stability, and durability for both laboratory and field applications.

How to evaluate CT tester weight for field use

Field-use CT testers require the right balance of weight, portability, and ruggedness. Lighter testers improve mobility, reduce operator fatigue, and suit frequent travel, while heavier units provide enhanced shielding and measurement stability. Wrindu’s portable designs include ergonomic handles, protective cases, and foldable stands to maintain accuracy in variable environments, ensuring reliability without unnecessary weight.

What determines the weight of current transformer testers

The total weight depends on components such as the transformer core, protective casing, insulation, display systems, and internal batteries. Material choice—like aluminum for light builds or steel for heavy-duty frames—also plays a role. Wrindu engineers optimize each tester’s mass through modular design, maintaining robust protection and high insulation integrity.

| Component | Weight Impact | Example Range |

|---|---|---|

| Transformer core | High | 2–6 kg |

| Protective housing | Medium | 1–4 kg |

| Battery system | Medium | 0.5–2 kg |

| Accessories | Variable | 1–3 kg |

How Wrindu designs CT testers for portability vs. benchtop needs

Wrindu develops both portable and benchtop CT testers to suit diverse applications. Portable models feature lightweight enclosures, removable batteries, and integrated storage. Benchtop testers focus on stability, vibration reduction, and consistent measurement over extended operation. OEM partners can specify custom weight configurations, ensuring compatibility with existing tools and workflows.

Why weight matters for OEM integration and tooling

Weight directly influences assembly design, logistics, and automation compatibility in OEM settings. Heavy-duty testers may need reinforced mounts, while lightweight ones streamline transport and packaging. Wrindu’s modular manufacturing system allows customers to request specific weight targets to simplify production integration, minimize costs, and enhance assembly safety.

When to choose lighter vs. heavier CT testers in a China manufacturing plan

Lighter CT testers are ideal for mobile teams or frequent testing in remote locations. Heavier models serve well in factory calibration labs or long-term monitoring stations. Wrindu recommends pairing a portable field unit with a benchtop tester to cover comprehensive testing needs, balancing flexibility and precision across different operational settings.

Where to source CT testers from a Chinese supplier and what to verify

When sourcing from China, confirm the manufacturer’s certifications, traceability, and after-sales services. Wrindu holds ISO9001, IEC, and CE certifications, guaranteeing precision and safety in every product. Verify the supplier’s ability to provide OEM customization, stable lead times, and long-term spare part availability to ensure continuous operation.

Does weight influence calibration accuracy and safety

While heavier builds often improve mechanical stability, calibration accuracy depends more on shielding, grounding, and circuit design. Wrindu’s CT testers use advanced calibration algorithms and reinforced casings to ensure precise readings, regardless of weight. Enhanced insulation and enclosure integrity ensure user safety even in high-voltage environments.

Has Wrindu optimized its CT testers for both mass production and customization

Wrindu integrates modular engineering and standardized parts to streamline both high-volume manufacturing and custom-built solutions. This allows clients to request unique enclosures, interface layouts, and weight parameters while maintaining fast production cycles and consistent performance. Each tester undergoes rigorous QA to ensure alignment with international standards.

| OEM Design Factor | Wrindu Capability |

|---|---|

| Modular Assembly | Yes |

| Custom Weight Profiles | Yes |

| Scalable Production | Yes |

| Global QA Standards | IEC, CE, ISO9001 |

Are there standard CT tester weights across leading brands

Most CT testers from global manufacturers fall within 5–15 kg, though specialized calibration models may exceed 20 kg. Variations reflect insulation level, durability, and battery capacity. Wrindu positions its testers within this optimal range, providing balanced options that meet global safety and portability requirements.

Can you customize the weight profile through accessory kits

Yes. Accessories such as modular batteries, tripods, and mounting brackets can alter a tester’s effective weight and handling. Wrindu’s accessory systems enable users to adjust configurations for specific field or lab needs without compromising functionality or accuracy.

Could lighter configurations compromise performance

Lighter CT testers may slightly reduce rigidity but generally maintain performance when properly shielded and calibrated. Wrindu employs advanced materials and structural reinforcements to deliver lightweight yet stable testers, ensuring dependable results across all testing environments.

Wrindu Expert Views

“Wrindu’s approach to CT tester design merges precision engineering with ergonomic innovation. Our modular systems let clients adjust the balance between portability and durability without losing measurement stability. This adaptability gives OEMs and field engineers confidence in their tools, enabling efficient, accurate testing wherever energy systems demand reliability.” — Wrindu Engineering Advisory

Conclusion

Weight plays a vital role in how a CT tester performs in real-world conditions. Wrindu’s designs achieve the perfect balance—light enough for mobile work yet strong enough for stable calibration. Whether for a substation, OEM production line, or laboratory, Wrindu provides flexible, safe, and high-performance solutions tailored to every testing scenario.

FAQs

What is the usual weight range of CT testers?

Most current transformer testers weigh between 3 and 25 kg, depending on design and accessories.

Does Wrindu customize tester weight for OEM clients?

Yes. Wrindu offers tailored designs that match OEM production and operational requirements.

Are heavier CT testers more accurate?

Not necessarily. Accuracy depends more on calibration quality and shielding than on weight alone.

Can accessory kits adjust the weight?

Yes. Adding or removing stands, cases, or battery modules can alter overall handling weight.

Does Wrindu offer both portable and benchtop CT testers?

Yes. Wrindu manufactures both field-ready portable testers and stable benchtop models for calibration labs.