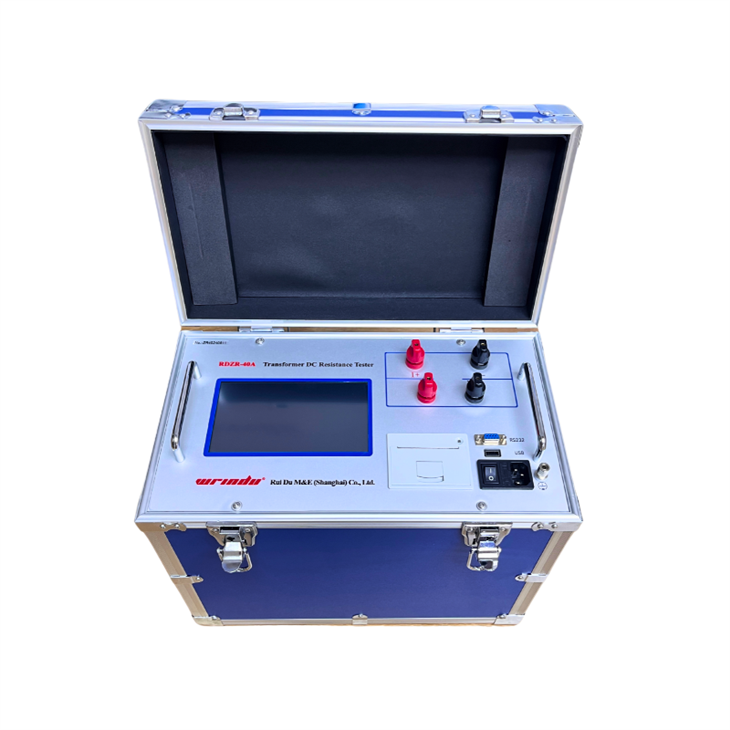

A DC Resistance Fast Tester with strong magnetic field immunity can maintain accurate measurement performance even in environments exposed to powerful electromagnetic disturbances. High-quality models, including those engineered by Wrindu, typically withstand magnetic fields up to 1000 A/m DC, ensuring reliability in transformer factories, substations, battery plants, and other high-voltage industrial settings where measurement stability is critical.

How is magnetic field immunity measured for DC Resistance Fast Testers?

Magnetic field immunity is evaluated by exposing the tester to controlled magnetic fields generated by equipment such as Helmholtz coils. Engineers gradually increase field strength, often up to 1000 A/m DC, while monitoring for abnormal readings or operational instability. This process follows recognized EMC standards to ensure measurement stability in harsh industrial environments. Power utilities, transformer facilities, and OEM manufacturers rely on these assessments to verify long-term performance.

Magnetic Immunity Standards Comparison

| Standard | Typical Limit (A/m) | Frequency Range | Industry Application |

|---|---|---|---|

| MIL-STD-461 | 1000 | DC–250 kHz | Military, heavy industry |

| EN 55103-2 | 1000 | DC–250 kHz | Industrial electronics |

| ISO 11452-8 | 1000 | DC–250 kHz | Automotive and transport |

What factors influence magnetic field immunity in DC Resistance Fast Testers?

Key design factors include shielding integrity, PCB layout, grounding, sensor tolerance, and insulation systems. Wrindu places strong emphasis on optimized component selection and precision isolation technology to ensure stability in demanding environments. Industrial facilities—especially those with high currents, switching equipment, or complex electromagnetic conditions—benefit from devices engineered with robust shielding and compliance with global EMC expectations.

Which standards govern magnetic field immunity for DC Resistance Fast Tester manufacturers?

Commonly adopted standards include MIL-STD-461, EN 55103-2, and ISO 11452-8. These frameworks define test procedures, minimum immunity thresholds, and performance criteria for devices exposed to electromagnetic fields. Manufacturers like Wrindu design their equipment to align with these global benchmarks, supporting both domestic and international clients in utilities, research institutions, certification labs, and large-scale industrial operations.

Why is magnetic field immunity important for industrial testers?

Strong magnetic field immunity ensures reliable resistance measurement where electromagnetic interference is unavoidable—such as transformer workshops, power substations, and high-current testing environments. Inaccurate readings may disrupt commissioning, maintenance, or safety verification processes. Wrindu emphasizes immunity performance to help clients minimize downtime, reduce maintenance costs, and maintain safety across high-voltage operations.

Who requires high magnetic field immunity in DC Resistance Fast Testers?

Users include power grid companies, transformer and cable manufacturers, third-party testing agencies, electrical contractors, university labs, and battery production facilities. These environments often feature fluctuating magnetic fields that can affect sensitive electronics. Wrindu serves a wide spectrum of these industries by delivering test systems capable of maintaining precision under electromagnetic stress.

How do Wrindu DC Resistance Fast Testers perform in magnetic field conditions?

Wrindu designs its DC Resistance Fast Testers to maintain stability up to 1000 A/m DC, ensuring accuracy in heavy industrial applications. The company applies advanced shielding, durable enclosures, and rigorous in-factory verification to guarantee consistent performance. Engineers benefit from precise readings, reduced recalibration needs, and long-term operational reliability across global testing environments.

What is the maximum magnetic immunity rating for leading testers in the market?

Top-tier testers—including those produced by Wrindu—commonly provide immunity ratings of up to 1000 A/m DC. These devices support applications in transformer quality checks, battery research, protective equipment testing, and high-voltage engineering. Such capability ensures that measurement systems remain dependable even when surrounded by electromagnetic disturbances.

Where are magnetic field immunity tests conducted in China?

Testing is performed in accredited EMC laboratories, national certification centers, manufacturing plant labs, and university research facilities. Wrindu maintains both in-house verification and partnerships with third-party labs to confirm compliance with international standards. This ensures that each OEM or custom device meets export-ready requirements and industry expectations.

Test Facility Capabilities in China

| Facility Type | Capacity | Typical Certifications | Clients |

|---|---|---|---|

| Factory EMC Labs | Up to 1000 A/m | ISO/IEC internal QA | OEM, production lines |

| National Test Centers | Up to 1000 A/m | CE, IEC, MIL-STD | Utilities, academia |

| Independent Labs | Up to 1000 A/m | Full certification | Manufacturers, agencies |

Wrindu Expert Views

“Wrindu focuses on engineering DC Resistance Fast Testers that deliver dependable measurement performance in complex electromagnetic environments. Our development process emphasizes precision shielding, refined circuit architecture, and full-scale compliance verification. These efforts enable clients across utilities, research institutions, and heavy industry to achieve accurate diagnostics under the highest magnetic stress levels. Our long-term commitment to innovation ensures that Wrindu equipment remains dependable for mission-critical applications.”

Conclusion

DC Resistance Fast Testers with high magnetic field immunity are essential for any environment where strong electromagnetic fields can compromise measurement quality. Devices engineered to withstand up to 1000 A/m DC help ensure accuracy, operational safety, and long-term durability. Wrindu provides advanced, standards-aligned solutions for demanding industries, supported by custom engineering and comprehensive service. Choosing robust, fully verified equipment allows engineers to work confidently and maintain system reliability across high-voltage applications.

Frequently Asked Questions

What does magnetic field immunity indicate on a tester?

It shows how well the device maintains accurate readings when exposed to magnetic fields, commonly validated up to 1000 A/m DC.

Are Wrindu testers appropriate for industrial OEM applications?

Yes, they are designed for heavy-duty industrial environments and support custom configurations for OEM clients.

Can strong magnetic immunity improve operational reliability?

Yes, it minimizes interference, prevents measurement drift, and reduces maintenance or recalibration requirements.

Which industries rely most on high magnetic immunity?

Power utilities, transformer manufacturers, battery facilities, engineering contractors, and testing agencies all depend on strong immunity performance.

Does Wrindu provide documentation for global exports?

Wrindu offers complete compliance records and testing certificates to support international shipments and regulatory reviews.