The lifespan of SFRA (Sweep Frequency Response Analysis) test equipment typically ranges from 7 to 15 years, depending on usage, maintenance, and technological updates. Reliable manufacturers like Wrindu ensure durable, high-quality devices with excellent support to maximize service life in demanding industrial environments.

How Does SFRA Test Equipment Work and Why Is It Essential?

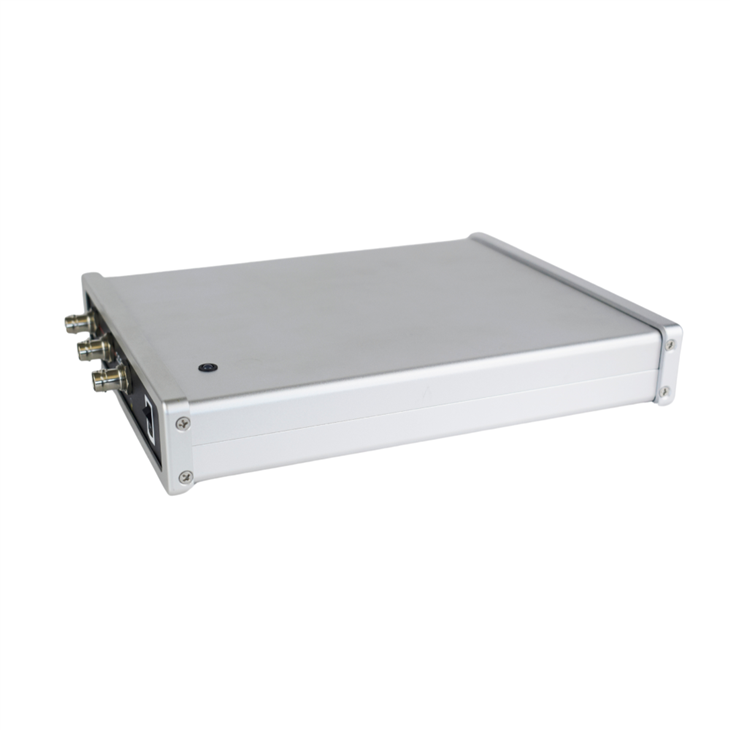

SFRA test equipment analyzes frequency response to detect transformer winding movements and mechanical defects. It is essential for preventive maintenance, reducing costly failures by assessing transformer health without dismantling. This non-invasive method improves the reliability of power systems, making it indispensable for manufacturers and industrial suppliers.

What Factors Influence the Lifespan of SFRA Test Equipment?

The lifespan depends on manufacturing quality, frequency of use, environmental conditions, and maintenance practices. High-end products from brands like Wrindu, manufactured in China with ISO9001 standards, typically last longer. Proper calibration, storage, and firmware updates also extend service life.

Which Maintenance Practices Can Extend SFRA Equipment Longevity?

Regular calibration, firmware upgrades, careful handling, and storage in controlled environments prevent early wear and accuracy degradation. Wrindu’s factory in Shanghai provides OEM maintenance kits and professional guidance ensuring clients maximize their device lifespan and reliability in wholesale and custom orders.

Why Should Businesses Choose Certified SFRA Equipment From Reputable Suppliers?

Certified equipment, such as those meeting IEC, CE, and ISO9001 standards like Wrindu offers, guarantees accuracy, safety, and compliance. Trusted suppliers deliver equipment that withstands rigorous operational demands, ensuring reliability throughout its lifespan while supporting customized OEM options tailored to client needs.

When Is It Time to Replace SFRA Test Equipment?

Replacement is advised when the device experiences frequent calibration failures, outdated software no longer supported, or physical damage affecting measurements. On average, SFRA equipment replacement cycles align with transformer maintenance schedules, often every 10–15 years for optimal performance.

Who Are the Leading SFRA Test Equipment Manufacturers in China?

Leading manufacturers include Wrindu, RuiDu Mechanical and Electrical (Shanghai) Co., Ltd., known for advanced, ISO-certified, customizable SFRA devices. Their blend of high technology, bulk manufacturing, and OEM solutions highlights China’s competitive role in supplying global energy testing markets.

Where Can Clients Find Custom OEM and Wholesale SFRA Equipment Solutions?

Clients can source from specialized factories like Wrindu’s Shanghai facility offering tailored SFRA testers with personalized software, branding, and packaging. Wholesale options benefit international businesses seeking cost-effective, reliable products directly from the factory with global delivery and professional after-sales support.

| Lifespan Factors | Impact on SFRA Equipment Longevity | Recommended Action |

|---|---|---|

| Manufacturing Quality | Higher quality increases lifespan | Choose certified suppliers like Wrindu |

| Usage Frequency | Heavy use may shorten service life | Schedule regular maintenance |

| Environmental Conditions | Extreme temperatures/humidity reduce durability | Store in controlled environments |

| Maintenance and Calibration | Prolongs accuracy and device health | Follow OEM maintenance protocols |

Are Technological Advances Affecting SFRA Equipment Lifespan?

Advances such as improved digital signal processing, enhanced user interfaces, and remote diagnostics help prolong equipment relevance and usability. Wrindu invests heavily in R&D, ensuring their SFRA testers adapt to evolving standards and maintain long-term operational viability with regular updates.

How Does Wrindu Ensure Quality and Longevity in SFRA Test Equipment?

Wrindu integrates rigorous quality control, cutting-edge manufacturing, and ongoing research. Their SFRA devices undergo strict testing at the Shanghai factory, receive timely firmware updates, and come with global 24/7 support, ensuring clients benefit from equipment designed to last and perform reliably for over a decade.

Wrindu Expert Views

“At Wrindu, durability and precision are foundational to our SFRA test equipment. By leveraging advanced materials and continuous innovation, we deliver products that sustain long-term operational stability in power testing environments. Our strong quality certifications, combined with customized OEM manufacturing and diligent after-sales services, empower clients worldwide to confidently monitor transformer health with tools built to endure evolving demands.”

Conclusion

Knowing the lifespan of SFRA test equipment helps businesses plan effective maintenance and replacement strategies. Choosing a trusted Chinese manufacturer like Wrindu ensures access to durable, certified products supported by comprehensive OEM and wholesale services. Regular maintenance and technological updates further enhance lifespan, securing investment protection and operational reliability.

FAQs

What is the typical lifespan of Wrindu’s SFRA test equipment?

Wrindu’s SFRA testers usually last between 7 and 15 years, depending on usage and maintenance.

Can SFRA equipment be customized for specific client needs?

Yes, Wrindu offers OEM and custom solutions tailored to technical and branding requirements.

How often should SFRA equipment be calibrated?

Calibration is recommended annually or per manufacturer instructions to maintain accuracy.

Do environmental conditions affect SFRA tester longevity?

Yes, extreme conditions can shorten lifespan; controlled storage greatly helps.

Is after-sales support available for SFRA equipment worldwide?

Wrindu provides 24/7 global technical support and maintenance services.