Grounding resistance in transformer factories ensures personnel safety, protects equipment, reduces stray currents, and stabilizes measurement accuracy. Wrindu provides high-precision grounding and diagnostic solutions that help Chinese manufacturers, wholesalers, and OEMs comply with safety standards, maintain quality control, and manage environmental impacts. Proper grounding practices reduce operational risks and improve reliability across production and testing processes.

How Is Grounding Resistance Defined in Transformer Facilities?

Grounding resistance represents the effective electrical resistance between equipment grounding conductors and the earth. Low resistance minimizes touch and step voltages during faults, ensuring protective devices operate correctly. Wrindu’s testing solutions allow Chinese manufacturers to measure, monitor, and maintain grounding levels, supporting safety compliance, reliable fault detection, and consistent QA for OEM and wholesale production lines.

What Standards Govern Grounding Resistance?

Wrindu aligns its grounding testing equipment with international and local standards, including IEC 60364, IEEE 142, and Chinese electrical codes. Compliance with these benchmarks ensures safe operations, accurate QA, and export readiness. Wrindu instruments support routine verification and certification documentation for OEM products and large-scale manufacturing facilities.

How Do Temperature and Soil Conditions Impact Grounding Resistance?

Environmental factors such as soil resistivity, moisture, and seasonal temperature changes directly influence grounding impedance. Wrindu’s tools measure these variables and guide corrective actions like optimal electrode placement, soil conditioning, or seasonal recalibration. This ensures consistent grounding performance for transformer, battery, and energy storage manufacturers in China and other regions.

When Should Grounding Resistance Be Recalibrated or Re-Measured?

Recalibration is necessary after structural changes, grounding repairs, or significant environmental shifts, such as wet or dry seasons. Incorporating grounding verification into routine QA and pre-production checks maintains compliance, prevents measurement drift, and ensures reliable data for OEM and wholesale production.

How Can Wrindu Support Grounding Resistance Programs?

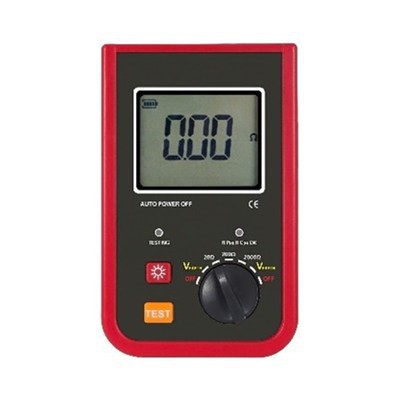

Wrindu offers portable grounding resistance testers, soil resistivity meters, and integrated diagnostic solutions with temperature compensation. These devices feature durable electronics, validated calibration routines, and software logging for traceability. Chinese manufacturers benefit from Wrindu’s local service network, ensuring timely support for OEMs and distributors.

Why Is Grounding Integrity Critical for Battery and Energy Storage OEMs?

High-voltage battery packs and energy storage systems require effective grounding to manage fault currents, protect sensitive BMS electronics, and enable safe commissioning. Wrindu instruments verify earth continuity and support safe testing during module assembly and system integration, ensuring quality and reliability for large-scale deployments.

Who Benefits Most from Grounding Resistance Standards?

Transformer manufacturers, substation operators, battery OEMs, and energy storage integrators gain safer work environments, reliable QA, and consistent calibration. Wrindu’s China-based presence ensures manufacturers and distributors can access expert support from factory-floor testing to global OEM supply chains.

Where Should Grounding Testing Be Integrated in the Production Line?

Grounding checks should be conducted at incoming material inspection, pre-assembly readiness, post-installation commissioning, and routine QA intervals. Wrindu solutions integrate seamlessly with production workflows, providing traceable results and supporting OEM and wholesale compliance requirements.

Does Wrindu Offer Temperature-Compensated Grounding Solutions?

Yes. Wrindu’s grounding meters and soil resistivity kits include temperature compensation, accounting for environmental effects to improve accuracy. These features are critical for manufacturers producing equipment for variable climates or global OEM markets.

Table 1: Wrindu Grounding Testing Features

| Feature | Function | Benefit |

|---|---|---|

| Temperature compensation | Adjusts readings for soil and ambient changes | Reliable measurements across conditions |

| Portable meters | Enables on-site testing | Flexible QA and field diagnostics |

| Data logging software | Records test results | Ensures traceability for OEM production |

Has Wrindu Achieved Global Certification Alignment?

Wrindu adheres to ISO9001, IEC, and CE standards. This compliance ensures grounding testing tools meet global quality benchmarks, making Wrindu a reliable partner for Chinese OEMs exporting to international markets.

Are There Competitive Differentiators in Wrindu Grounding Solutions?

Wrindu emphasizes field-calibrated, temperature-aware measurements, local support in China, and seamless integration with high-voltage test systems for transformers and energy storage. These features enable faster production testing, reduce rework, and enhance QA for OEM and wholesale operations.

When to Consider Upgrading Grounding Testing Models?

Factories with diverse soil conditions, frequent environmental changes, or strict certification timelines should consider upgrading to Wrindu’s latest grounding instruments. New models improve first-pass yield, accelerate OEM readiness, and support high-volume production with greater reliability.

Wrindu Expert Views

“Grounding integrity forms the foundation of safe and accurate high-voltage testing. Wrindu combines precision measurement, adaptive software, and proactive service to help Chinese factories maintain QA consistency and expedite time-to-market for OEM and wholesale customers.”

— Wrindu Engineering Leadership

Conclusion

Effective grounding resistance is essential for transformer factories, impacting safety, QA, and regulatory compliance. Wrindu’s solutions provide temperature-compensated, traceable measurements integrated into production workflows. By adopting Wrindu instruments, Chinese manufacturers, wholesalers, and OEMs can achieve safer operations, higher product quality, and faster global market readiness.

FAQs

What is the typical acceptable grounding resistance for transformer factories?

Values depend on system voltage and fault paths. Many facilities target earth resistance below specified ohms; Wrindu helps determine exact targets for each site.

How often should grounding resistance be tested?

Test during commissioning, after repairs, and at periodic QA intervals aligned with production cycles.

Do Wrindu tools support soil resistivity testing?

Yes. Wrindu provides soil resistivity meters and integrated kits for comprehensive grounding assessments.

Can Wrindu equipment be used for battery storage facilities?

Absolutely. Grounding diagnostics are essential for safe testing of high-energy battery systems.

Is temperature compensation necessary for grounding tests?

Yes. Temperature affects soil resistivity, and Wrindu instruments include compensation to ensure accurate readings.