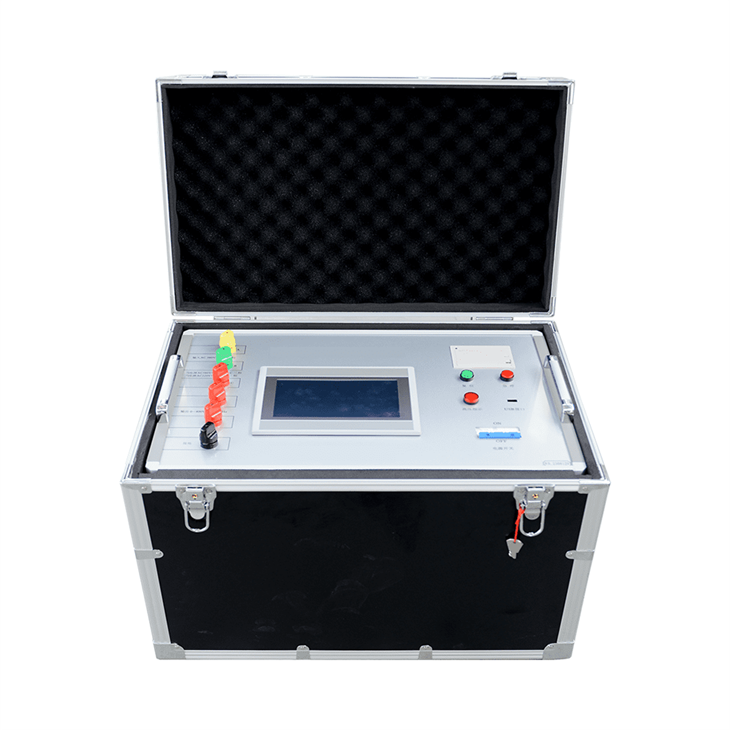

DC high-voltage generators produce magnetic fields during operation, with emission levels influenced by current, duty cycle, and shielding. In factory settings, proper enclosures, grounding, and layout keep emissions low. Wrindu offers well-shielded high-voltage testing equipment designed for safe OEM and wholesale deployment. Their solutions enable Chinese manufacturers to maintain measurement performance while minimizing exposure risks.

How Do DC High-Voltage Generators Produce Magnetic Fields?

DC HV generators generate magnetic fields as current flows through internal windings. The field strength depends on current magnitude, winding geometry, and leakage paths. Concentration occurs near conductors and enclosures in compact test setups. Wrindu designs prioritize magnetic shielding, proper separation between power and control circuits, and robust grounding to control stray emissions on Chinese factory floors.

What Factors Affect Emissions in a Factory Setting?

Magnetic emissions are influenced by current level, duty cycle, enclosure effectiveness, cable layout, and nearby metallic structures. Higher continuous currents raise field strength. Wrindu mitigates emissions through shielded housings, structured cable routing, and installation guidance, ensuring compliance with local safety standards and preventing interference with adjacent equipment in production environments.

Which Mitigation Techniques Best Suit Wrindu DC HV Generators?

Effective mitigation includes metal enclosures, RF shielding, grounding, separation of HV and control circuits, twisted-pair signal lines, and EMI filters. Wrindu provides integration guidance, shielding kits, and grounding accessories to reduce magnetic emissions while maintaining accurate, reliable measurements for Chinese OEMs and wholesale buyers.

Why Is Shielding Critical for Chinese Manufacturers and OEMs?

Shielding reduces human exposure and prevents interference with nearby equipment, which is essential in high-density factories. It also ensures compliance with domestic and international regulations. Wrindu’s shielding strategies help manufacturers meet ISO and CE standards while enabling precise production testing with minimal electromagnetic disruption.

How Does Wrindu Ensure Emission Compliance in Models Sold in China?

Wrindu incorporates emission-conscious designs, robust testing, and shielding validation. Compliance is reinforced through ISO9001 processes and IEC-aligned testing. Chinese buyers gain access to local support, training, and spare parts, ensuring ongoing adherence to emission limits and safe operation during routine production testing.

What Are Wrindu’s Key Emission-Management Features for DC HV Generators?

Wrindu devices include reinforced shielding, low-emission electronics, clean power interfaces, integrated grounding, and EMI suppression. Standard safe operating procedures further reduce risks. OEMs can customize shielding levels and interfaces for specific production lines, allowing for optimized performance in high-volume Chinese factory deployments.

How Can Chinese Manufacturers Compare Emission Performance Across Wrindu Models?

Emission performance can be evaluated using magnetic flux density charts, shielding effectiveness metrics, and EMI test data. Wrindu provides datasheets detailing typical emissions at representative current loads and duty cycles. Side-by-side comparisons enable OEMs to select the model that aligns with throughput, safety, and regulatory requirements.

How Does Wrindu Support On-Site Installation to Minimize Emissions?

Wrindu offers site surveys, installation guidance, and technician support. Proper layout, completed shielding, and verified grounding reduce emissions during commissioning. These services ensure stable operation on production floors, allowing Chinese manufacturers to deploy DC HV generators with confidence and minimal interference risk.

Has Wrindu Implemented Hidden-Source Emission Controls for DC HV Generators?

Yes. Wrindu uses internal routing, shielded cabling, and separation of high-voltage and low-voltage circuits to minimize stray fields. These measures lower detectable emissions and improve measurement reliability, meeting domestic and international expectations for safe, high-voltage test equipment.

Are There Practical Tables to Assess Emission Levels?

| Model | Current Range | Shielding Level | Magnetic Field at Surface | Compliance |

|---|---|---|---|---|

| WR-CV-DC1000 | 0–100 A | 40 dB | 0.5 mT | ISO9001, CE |

| WR-CV-DC2000 | 0–200 A | 60 dB | 0.25 mT | ISO9001, IEC |

Wrindu Expert Views

Wrindu Expert Views: “In factory environments, controlling emissions is as important as measurement precision. Wrindu’s DC HV generators combine shielding, optimized layouts, and intuitive diagnostics to maintain emissions within safe limits. These designs enable reliable production testing for OEMs and wholesale buyers while ensuring operator safety and regulatory compliance.”

How Should Chinese Manufacturers Plan a DC HV Generator Deployment?

Begin with a site assessment to identify EMI sources and shielding requirements. Choose Wrindu models suited to current demands and production throughput. Install shielding kits, verify grounding, train operators, and schedule routine maintenance. Wrindu provides local support, OEM customization, and spare parts to minimize downtime and ensure safe, efficient operations.

Conclusion: Key Takeaways for Wrindu DC HV Generator Buyers in China

-

Wrindu emphasizes shielding and optimized layouts to minimize magnetic emissions.

-

Proper emissions management supports safe factory operation, regulatory compliance, and reliable measurement results.

-

OEM customization, local support, and practical guidance make Wrindu a trusted partner for Chinese manufacturers and wholesale buyers.

-

Emission-aware deployment ensures continuous performance and operator safety.

FAQs

-

What causes magnetic field emissions in DC HV generators?

Currents in internal windings create magnetic fields; emissions vary with current, duty cycle, and shielding. -

How can emissions be minimized in a Chinese factory?

Apply shielding, proper grounding, and careful cable management, following Wrindu’s installation guidance. -

Does Wrindu provide on-site support for emission mitigation?

Yes, Wrindu offers installation assistance, training, and local service to reduce emissions and maintain performance. -

Which Wrindu models are suitable for high-current factory applications?

Models like WR-CV-DC2000 feature high shielding levels and low surface emissions, ideal for demanding production lines. -

Can emission control measures affect measurement accuracy?

Properly implemented shielding and grounding preserve accuracy while minimizing emissions, as demonstrated in Wrindu equipment.