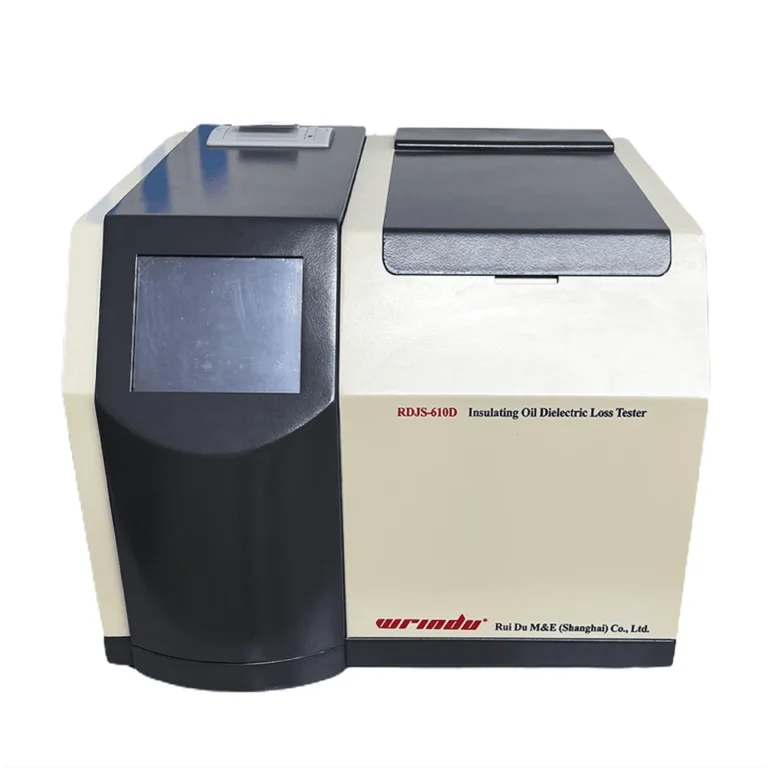

Oil testing

RuiDu Mechanical: Your Reliable Oil Testing Equipment Supplier!

RuiDu Mechanical and Electrical (Shanghai) Co., Ltd. is a leading global power testing equipment manufacturer and system solution provider. Our company was established in 2014. Our main products are substation transformers, high-voltage switches, transformers, lightning arresters, batteries, cable faults, relay protection, insulation withstand voltage, transformer oil injection equipment, etc. Our factory covering an area of more than 50,000 square meters, 6 product production lines and more than 200 employees, selling the products to more than 120 countries and regions. In addition, we support high-volume production, calibrate and test instruments at the point of sale, providing repair instructions for these products.

Rich Experienced

Our team has more than 10 years of experience in the industry, providing customers with compliant, high-quality equipment, and developing friendly cooperation with partners such as Kenya Power, UETCL, TCN, EVN, PLN, NGCP, CFE.

Wide Product Range

Our broad product offering includes digital multimeters, power analyzers, thermal imaging cameras, insulation resistance testers, accessories and integrated test tools. These test devices can be easily integrated into a variety of electrical and electromechanical systems.

Guaranteed Quality

Our production workshops are professionally assessed, developed and validated, equipped with a range of analytical instruments and all products have international ISO 9000 series, IEC and CE certifications.

Customized Service

According to your usage needs, our team is online 24/7 to provide you with detailed consultation and after-sales service, and provide OEM and ODM customized products.

What is Transformer Oil Testing Equipment?

Transformer oil, a type of insulating and cooling oil used in transformers and other electrical equipment, needs to be tested periodically to ensure that it is still fit for purpose. This is because it tends to deteriorate over time. Transformer oil testing equipment measures the quality and condition of transformer insulating oil, also the breakdown voltage and chemical and physical properties of transformer oil. The industry practice is to regularly test transformer oils and insulating oils, general and physical tests are suggested twice a year.

Features of Transformer Oil Testing Equipment

High Compatibility

These transformer oil testers are compatible with a variety of headspace samplers to reliably measure decomposition products in transformer oil, including H2, O2, CO, CO2 and C1–C3, and generate customizable reports according to ASTM standards.

Remote Operation

These detectors support remote networked operation and monitoring for unattended operation, allowing you to monitor the system, check system logs, perform diagnostic tests, and change methods without using a chromatography data system.

Wide Applications

They are equipped with dual hydrogen flame ionization detectors (FID), thermal conductivity cells (TCD) detectors and methane reformers, and are widely used in petroleum, electric power, coal, chemical industry, scientific research and other fields.

Easy to Use

These devices adopt a simple operating process. As long as the extract is injected into the instrument, the instrument will automatically search for the sample, inject the extract, perform blank titration, perform experiments, clean, display printed results and other operations.

Reasons to Use Transformer Oil Testing Equipment

Transformer Oil Use Growing Globally

Global transformer oil usage is expected to grow substantially by 2020. The Asia-Pacific area, especially China and India, are the largest consumers of transformer oils due to the expansion of electric networks increasing the installation and upgrade of transformers in turn increasing the demand for transformer oil.

Over time this oil is exposed to mechanical and electrical stress as well as to chemical contamination. When the functionality is reduced it can lead to power outages. To maintain and extend the life of the power transformer and to avoid severe breakdowns, regular testing of the transformer oil is very important. The ASTM D971 standard is used to define the general electrical and physical properties of transformer oil.

Important Standard for Several Industries

So what does this standard mean in practice? Well, it determines the possible contaminants of hydrocarbon fluids. The purity of hydrocarbon fluids is important in other industrial areas besides transformer oils such as in aviation, and diesel fuels. For example, jet fuel needs to be highly purified as water or dirt contaminations can cause serious danger in flight safety. Surfactants in jet fuel can cause the lifting of rust in storage tanks as well as absorption of water on coalescing surfaces. The ASTM D971 standard is also a useful indicator of the cetane number of diesel fuels. The cetane number of diesel fuels is used to define the quality of combustion during ignition.

Increases Safety

Oil testing helps to ensure that equipment is operating safely. By identifying potential issues with oil, such as contamination or degradation, maintenance teams can take corrective measures to prevent equipment failure. This can prevent accidents and injuries that can occur when equipment fails unexpectedly.

For example, if oil analysis shows that the oil is contaminated with dirt or debris, maintenance teams can take corrective measures to prevent the buildup of debris in the equipment, which can cause overheating and potential fires. By addressing these issues early, maintenance teams can prevent accidents and injuries that can occur when equipment fails unexpectedly.

Types of Transformer Oil Testing Equipment

A transformer oil tester, which is also called a transformer oil test kit, is a tool used to measure the dielectric strength, acidity, water content, and other properties of transformer oil. There are different kinds of transformer oil testers available, each with its own set of features and capabilities. Some common kinds of transformer oil testers include:

Dielectric Strength Testers

These read out the oil’s breakdown voltage and measure the dielectric strength (DS) of the transformer oil.

Water Content Testers

These measure the quantity of water present in the transformer oil and provide a readout in parts per million (ppm) or percentage.

Acid Number Testers

These measurements determine the acidity of transformer oil and provide a readout in terms of acid number (AN) or total acid number (TAN).

Gas Chromatography Testers

These test the amount of dissolved gases in transformer oil and give a detailed list of the different kinds of gases that are there.

Furan Testers

These measurements are the levels of furan compounds present in transformer oil that are produced by the breakdown of the transformer’s cellulose insulation. Depending on the application and the level of accuracy required, these testers can be portable, handheld, or bench-top models. Utility companies, companies that make transformers, and maintenance crews all use them to make sure that electrical power transformers work safely and reliably.

Dielectric Strength Testers

A transformer oil dielectric tester, also known as a transformer oil breakdown voltage tester, is a device used to measure the dielectric strength, or breakdown voltage, of transformer oil. The dielectric strength (DS) of transformer oil is a key property that shows how well it can keep electricity from arcing and short-circuiting inside the transformer.

These testers can be portable and handheld for on-site testing or in a bench-top version for laboratory use, depending on the need for application and the level of accuracy required.

Water Content Testers

Transformer oil water content is measured using equipment called water content testers. Water is harmful to transformer oil, as it can damage the insulating properties of the oil and lead to the formation of sludge and acids. So, it’s important to keep an eye on the amount of water in transformer oil and take action if it goes above a certain level. The water content of transformer oil can be measured by several methods. Some of the common methods are:

●Karl Fischer Titration

This method uses a reagent that reacts with water to produce a chemical reaction that can be measured. The amount of water present in the oil is calculated based on the amount of reagent used.

●Coulometric Karl Fischer Titration

A variant of the Karl Fischer titration method that measures the water content of oil using electrical current. Crackle Test is an on-site method that uses a low-voltage spark to create a crackling sound when applied to transformer oil. The sound changes as water is present in the oil.

●DGA (Dissolved Gas Analysis)

With this technique, the amount of dissolved gases in a sample of transformer oil is measured. The presence of dissolved gases such as hydrogen and methane, could indicate that the transformer is overheating and water is present in the oil.

●Moisture Sensor

This technique measures the water content by utilizing the electrical characteristics of transformer oil. It typically involves immersing a probe into the transformer oil and measuring the electrical resistance of the oil.

All these methods give the water content in either percentages or parts per million (ppm). It’s important to note that, as per industry standards, the water content of transformer oil should not exceed 30 ppm.

Acid Number (AN) Testers

Acid number (AN) testers, also known as total acid number (TAN) testers, are devices used to measure the acidity of transformer oil. Acidity is an important property of transformer oil because it shows that acidic impurities like oxidation products, sludge, and dissolved gases are present. These impurities can cause acids to form, which can damage the dielectric insulation of the transformer and weaken the dielectric strength of the oil.

The acid number of transformer oil is typically measured in terms of mg of KOH per gram of oil (mg KOH/g). The lower the acid number, the less acidic the oil is. The industry standard for the acid number in transformer oil is 0.03, 0.01, or less mg KOH/g.

Transformer Oil Testing Procedure

●To assess the insulating property of dielectric transformer oil, a sample of the transformer oil is taken and its breakdown voltage is measured. The lower the resulting breakdown voltage, the poorer the quality of the transformer oil.

●The transformer oil is filled in the vessel of the testing device. Two standard-compliant test electrodes with a typical clearance of 2.5 mm are surrounded by the dielectric oil.

●A test voltage is applied to the electrodes and is continuously increased up to the breakdown voltage with a constant, standard-compliant slew rate of e.g. 2 kV/s.

●At a certain voltage level breakdown occurs in an electric arc, leading to a collapse of the test voltage.

●An instant after ignition of the arc, the test voltage is switched off automatically by the testing device. Ultra fast switch off is highly desirable, as the carbonisation due to the electric arc must be limited to keep the additional pollution as low as possible.

●The transformer oil testing device measures and reports the root mean square value of the breakdown voltage.

●After the transformer oil test is completed, the insulation oil is stirred automatically and the test sequence is performed repeatedly: typically 5 repetitions, depending on the standard.

●As a result the breakdown voltage is calculated as mean value of the individual measurements.

How to Analyze the Fluid Quality of Transformer Oil?

In our TOT, each parameter is analysed to provide diagnostic information on the transformer insulating oil as detailed below:

Colour And Appearance– Changes in colour and the physical appearance of the insulating fluid can highlight changes within the system. The presence of physical particles, changes in colour, the presence of free water or the turbidity of the fluid can all be identified.

Water Content– Elevated levels of water can damage the mechanical strength of the paper insulation and deteriorate the insulating fluid. Ingress can be from external sources (poor maintenance activities) or internal degradation of the paper or fluid. Once lost, the paper does not recover its mechanical properties. It is worth noting that doubling the water content can half the working life of a transformer.

Dielectric Strength– Inservice insulating fluids must withstand electrical stress without failure. Contaminants such as water, conducting particles, polar compounds, can reduce the dielectric strength of the fluid.

Acidity -Oxidation of the insulating fluid will occur during its service and form acidic products. Often noticed with a darkening of the fluid colour and if left unchecked can cause internal corrosion, degradation of paper and ultimately the formation of sludge.

Interfacial Tension (Ift)– Determines the presence of soluble polar material and products of fluid degradation. Changes to IFT values suggests fluid degradation, or perhaps incompatibility with other fluids through top-up, or other materials (gaskets etc).

Dielectric Dissipation Factor (Ddf) -Measure the current leakage in the insulating fluid. Directly affected by the level of polar contaminants in the fluid. During service the DDF value tends to increase.

Resistivity-The fluids ability to resist the flow of direct current. Directly affected by the level of polar contaminants in the fluid. During service the resistivity value tends to reduce.

Furanic Compounds -Organic compounds formed during degradation of the paper insulation. Tool to determine the remaining useful life of the paper insulation via a relationship with the degree of polymerisation value of the cellulose.

Degree of Polymerisation (Dp) – The predicted DP value indicates the average paper condition across the whole of the transformer. Provides an indication on the remaining useful life of the insulation and consequently the transformer.

Polychlorinated Biphenyls (Pcb) – Organic chlorinated compounds, previously used as transformer insulating fluids but subsequently banned due to health and environmental concerns. Now classified as Persistent Organic Pollutants and controlled as part of the Stockholm Convention. All transformers should be measured to determine the PCB content.

Factors to Consider When Choose Transformer Oil Testing Equipment

01/ Understanding Transformer

Oil Transformer oil, also popular as dielectric or insulating oil, is a specialized oil used in electrical transformers and other high-voltage electrical equipment. Its primary function is to serve as both an electrical insulator and a cooling medium. This dual role is essential for ensuring the efficient and safe operation of transformers and other similar equipment.

02/ Insulating Properties

One of the most critical functions of transformer oil is its ability to insulate the components of the transformer, such as the windings and core, from each other and from the transformer’s metal casing. Electrical insulation prevents the flow of electricity between these components, which is crucial for maintaining the proper functioning of the transformer. Without effective insulation, electrical breakdowns and short circuits could occur, leading to equipment failure and potential safety hazards.

03/ Cooling and Heat Dissipation

Transformers generate heat during operation due to the electrical resistance in the windings and the core. If this heat is not managed properly, it can lead to overheating and degradation of the transformer’s components. Transformer oil helps dissipate this heat, keeping the temperature within safe limits. It flows through the winding and core, carrying away the excess heat and allowing the transformer to operate efficiently.

04/ Preventing Arcing and Corona Discharge

In addition to its insulating and cooling properties, transformer oil also helps prevent the occurrence of arcing and corona discharge. Arcing is the sudden discharge of electricity between two conductive surfaces, which can lead to equipment damage and fire hazards. Corona discharge is a phenomenon where localized ionization occurs around high-voltage conductors, potentially causing ozone production and insulation deterioration. The presence of transformer oil helps to mitigate these issues and maintain the integrity of the equipment.

Certificate Photo

Factory Photo

FAQ

Q: What is the protective relay function test?

A: The functional tests consist of using the adequate inputs to the protection relay under test and measuring the performance to discover if it meets the specification. They are typically completed under controlled environmental conditions.

Q: What is the relay function test system?

A: The Relay Functional Test is a system that allows validation of all the relays commutation phases and control of their own consumption. This system ensures the wiring delivery with all the relays accurately working.

Q: How often should protection relays be tested?

A: Every 2 years. Due to their critical role in the power system, protective relays should undergo acceptance testing before being placed in service and periodic testing thereafter to ensure reliable performance. In a typical industrial application, testing should be conducted at least every 2 years in accordance with NFPA 70B.

Q: What are the different types of testing for relays?

A: Tests vary based on the relay technology, but may include: Visual and mechanical inspection. Insulation resistance measurements. Secondary injection tests.

Q: What is the easiest way to test a relay?

A: To test this, leave your multimeter on the ohms setting and measure the resistance between the switch pins. On a four-pin relay, these are typically labeled 87 and 30. You should see no resistance at all between these pins. If you do, that means that the pins are stuck closed and the relay is bad.

Q: What are the three main types of relays?

A: There are a variety of different types of relays for a variety of different uses. The three most commonly used types are electromechanical relays (EMR), solid-state relays (SSR), and Reed relays.

Q: How much resistance should a relay have?

A: Between 50 ohms and 200 ohms. The electrical resistance (impedance) of the coil is vary and is different depending upon the manufacturer of the relay as well as relay’s type, but in general a typical value should be expected between 50 ohms and 200 ohms. Input current typically is in the range between 100 mA and 150 mA.

Q: What causes a relay to fail?

A: The two most common failure mechanisms of relays are contamination and mechanical wear of the internal switching elements discussed as follows: a. Contamination is a major cause of early life failures.

Q: Can an electrical relay go bad?

A: Many electrical components in a vehicle or machine are controlled by a relay. So if a component isn’t working because electricity isn’t getting to it, there is a possibility the relay may be faulty. But determining whether or not a relay is defective requires a little basic investigation. Here’s how to go about it.

Q: How many years do relays last?

A: Relays generally last around 200,000 cycles on average (roughly 18+ months depending on usage, firing temperature, and firing profile), but can fail long before or long after without any explanation.

Q: Can a car relay be tested?

A: If it is still not working, it may be necessary to use a test light or multimeter to double-check your incoming and outgoing power, ground, and continuity, but testing the relay itself may be as simple as turning the ignition or auxiliary switch on and off and listening for a click.

Q: How do I identify a relay?

Q: How many amps is a relay rated for?

A: These rating indicate how much power can be switched through the relays. This does not necessarily tell you what the limits of the relay are. For instance, a 5 Amp relay rated at 125VAC can also switch 2.5 Amps at 250VAC. Similarly, a 5 Amp relay rated at 24VDC can switch 2.5 Amps at 48VDC, or even 10 Amps at 12VDC.

Q: How many volts should a relay have?

A: Generally a relay coil is rated by voltage, not current. If it is a relay with a 12 volt coil, it will operate at approximately 12 volts. Unless the coil is damaged, it will not draw too much current as long as the emf applied to it is approximately 12 volts, perhaps as low as 9 volts or as high as 16 volts.

Q: Which relay is mostly used?

A: Electromagnetic relay is the simplest, oldest and most widely used relay. Its basic components are coils, magnetic cores, armatures, springs and contacts. The magnetic system is used to convert the input current into the mechanical power required for contact closure.

Q: What appliances use relays?

A: Relays make it possible to start up electric and electronic gadgets and appliances such as refrigerators, cars, computers, cell phones, furnace fans, industrial equipment, conveyor belts, and more.

Q: How many terminals does a relay have?

Q: What electronics contain relays?

A: Control relays are used in motors, power plants, power supply systems, transistors, and more. Polarized relays are affected by the direction of electrical current. The direction of the current affects the operation of these relays, as the armature inside is permanently magnetized.

Q: Which relay is used for protection?

A: The digital protective relay or numeric relay is a protective relay that uses a microprocessor to analyze power system voltages, currents or other process quantities for detection of faults in an industrial process system. A digital protective relay’s operating principle ranges from simple to complex.

Q: Would a bad relay throw a code?

A: On some vehicles, the engine computer, which is often referred to as the powertrain control module (PCM) monitors the fuel pump relay and its circuit. If the PCM detects a problem, it turns on the check engine light and stores a corresponding diagnostic trouble code (DTC) in its memory.