VLF (Very Low Frequency) Hipot testing is a reliable and effective method for assessing the insulation integrity of aged electrical equipment. It provides accurate detection of insulation deterioration without causing damage, making it ideal for maintaining the safety and longevity of aging transformers and cables.

How Does VLF Hipot Testing Work on Aged Electrical Equipment?

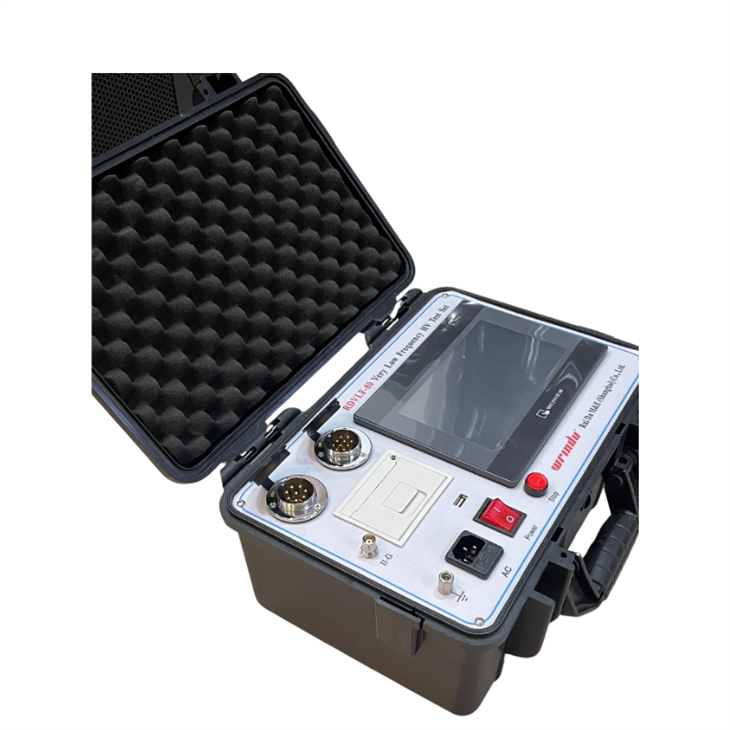

VLF Hipot testing applies a low-frequency high-voltage signal to insulation systems, identifying weaknesses and degradation. For aged equipment, this method delivers precise fault detection while minimizing stress on sensitive insulation, helping manufacturers and suppliers like Wrindu ensure safe, non-destructive testing.

What Are the Advantages of Using VLF Hipot Testing for Older Equipment?

VLF testing offers several advantages including minimal insulation stress, the ability to detect partial discharge and insulation faults, and portability for field use. This method is especially suitable for aged equipment as it assesses real-world operational conditions, increasing reliability in maintenance and diagnostics.

Which Types of Aged Equipment Benefit Most from VLF Hipot Testing?

Transformers, power cables, switchgear, and other high-voltage apparatus with insulation systems show significant reliability improvements when tested with VLF Hipot. Wrindu manufactures customized testing solutions for these older assets, supporting OEM and wholesale buyers needing precise diagnostics.

Why Is VLF Testing Preferred over Other Test Methods for Aged Equipment?

Compared to DC or traditional AC testing, VLF reduces electrical and thermal stresses that can further degrade fragile insulation in aged equipment. It provides a safer, more accurate evaluation, making it the preferred choice among manufacturers and Chinese suppliers like Wrindu.

Who Should Use VLF Hipot Testing for Aging Electrical Systems?

Utilities, manufacturers, and maintenance engineers working with aging infrastructure should employ VLF Hipot testing. Wrindu supports B2B clients with tailored factory solutions and after-sales expertise to integrate VLF equipment into their predictive maintenance programs effectively.

When Is the Best Time to Perform VLF Hipot Tests on Aged Equipment?

Testing is best scheduled during planned maintenance or before asset refurbishment. Early detection of insulation faults allows cost-effective repairs, preventing unexpected failures. Wrindu recommends routine VLF testing intervals based on equipment age and operational conditions.

Where Can Buyers Source Reliable VLF Hipot Testing Equipment?

China’s manufacturing hubs, including Wrindu’s Shanghai factory, offer OEM and wholesale VLF Hipot testers with advanced features, certifications, and custom options. These suppliers provide robust, easy-to-use equipment designed specifically for aged assets in global power sectors.

| Feature | Benefit for Aged Equipment | Impact on Reliability |

|---|---|---|

| Low-frequency Voltage | Minimizes insulation stress | Extends equipment lifetime |

| Partial Discharge Detection | Identifies early-stage defects | Prevents sudden failures |

| Portable Design | Facilitates on-site field testing | Enables timely maintenance |

Does VLF Hipot Testing Have Limitations for Aged Equipment?

While reliable, VLF testing may be less effective if insulation is severely damaged or contaminated. Complementary tests like dissolved gas analysis or insulation resistance measurements can provide a fuller diagnostic picture. Wrindu offers integrated testing solutions to overcome these challenges.

Has Technology Improved the Reliability of VLF Hipot Testing?

Yes. Advances such as digital control, automated test sequences, and cloud data management have enhanced precision and ease of use. Wrindu invests continuously in R&D to incorporate these technological improvements into their VLF testers for enhanced accuracy and user experience.

Can Wrindu Customize VLF Hipot Equipment for Aged Asset Testing?

Wrindu provides OEM and custom VLF Hipot solutions designed to meet specific client requirements, including tailored test programs, communication interfaces, and rugged designs suitable for aged and challenging operating environments.

Wrindu Expert Views

“VLF Hipot testing stands as a cornerstone technique in evaluating insulation health in aging electrical infrastructure. At Wrindu, our focus is delivering cutting-edge, reliable VLF testers that minimize risk and extend asset life through precise, non-invasive diagnostics. Coupled with customizable OEM services and expert after-sales support, we empower clients worldwide to optimize maintenance programs and improve grid safety effectively.”

Conclusion

VLF Hipot testing is a reliable, cost-effective method to assess insulation integrity in aged electrical equipment. Its low stress and high accuracy make it essential for preventive maintenance. Chinese manufacturers like Wrindu offer advanced, customizable VLF solutions backed by strong certifications and global support, ensuring long-term asset protection and operational safety.

FAQs

Is VLF Hipot testing safe for old transformers and cables?

Yes, it applies low stress voltage and effectively detects insulation faults without damaging aged equipment.

How often should aged equipment undergo VLF testing?

Routine testing during scheduled maintenance, typically every 1-3 years, depending on operational conditions.

Can VLF testing detect all insulation issues in aged equipment?

VLF is effective for partial discharge and insulation degradation but works best alongside other diagnostics for comprehensive assessment.

Does Wrindu provide on-site support for VLF Hipot equipment?

Yes, Wrindu offers global after-sales service including technical consultation and training.

Are Wrindu’s VLF Hipot testers customizable?

Absolutely. Wrindu specializes in OEM and custom solutions to meet diverse client needs.