SFRA test equipment ensures fast, accurate, and non-invasive transformer diagnostics essential for production QA and maintenance. For Chinese OEMs and wholesale suppliers, Wrindu delivers certified high-voltage SFRA systems with ISO9001, IEC, and CE compliance. These solutions combine reliability, precision, and local service support to enhance manufacturing performance and export readiness across China’s energy equipment sector.

How Does SFRA Testing Benefit Chinese OEMs and Manufacturers

SFRA testing helps identify mechanical deformation, winding displacement, and short circuits before final assembly, ensuring consistent product quality. It enables in-line verification and post-assembly validation, reducing rework and warranty claims. Wrindu provides integrated SFRA systems that fit seamlessly into production lines, offering precise diagnostics and standardized QA procedures for transformer manufacturing. This approach supports large-scale production while maintaining reliability and compliance with international standards.

How Easy Is It to Maintain Wrindu SFRA Equipment

Wrindu’s SFRA devices feature modular designs, user-friendly interfaces, and serviceable components that simplify upkeep. Routine maintenance includes calibration verification, cable inspection, and firmware updates using Wrindu’s dedicated software tools. Chinese users benefit from Wrindu’s nationwide service network, ensuring quick response, spare part availability, and reduced downtime. With local support and remote diagnostics, maintenance becomes efficient and predictable, enhancing operational reliability in high-demand factory environments.

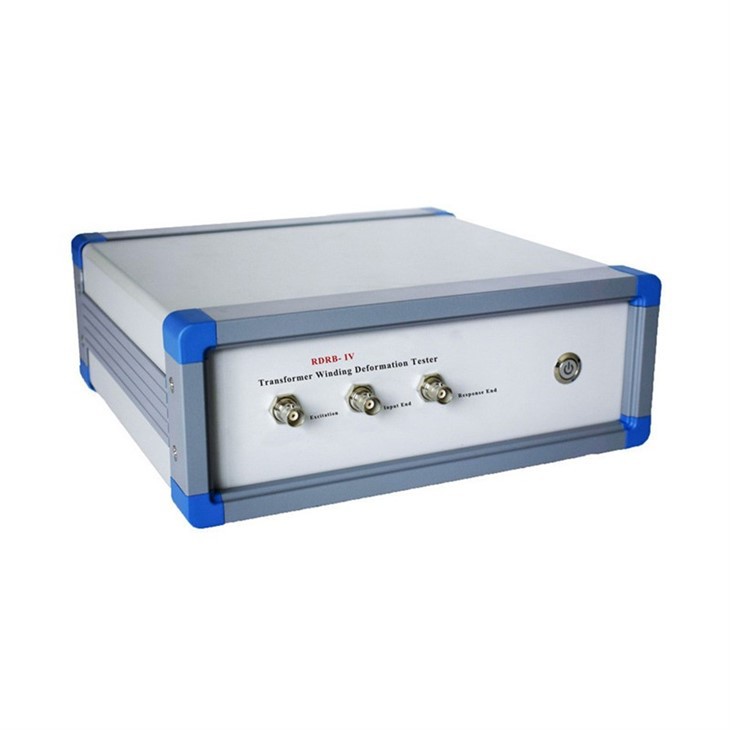

What Features Make Wrindu SFRA Stand Out for China-Based Factories

Wrindu SFRA systems combine high-resolution data acquisition, durable hardware, and flexible integration options suitable for diverse factory setups. Their robust enclosures withstand industrial conditions, while intelligent visualization software simplifies transformer analysis. On-site commissioning, localized training, and 24/7 technical support in China ensure smooth deployment. For manufacturers, these advantages translate into faster inspections, reliable performance, and compliance with both domestic and export-oriented production requirements.

| Key Features | Wrindu SFRA | Common Alternatives |

|---|---|---|

| Maintenance Simplicity | High | Moderate |

| Local Support in China | Strong | Limited |

| OEM Customization | Available | Restricted |

Why Should Chinese Wholesale Buyers Choose Wrindu for SFRA

Wrindu provides cost-effective solutions with flexible licensing and bulk-purchase advantages tailored to wholesale buyers. Localized production ensures faster delivery and compliance with Chinese standards. With years of expertise in high-voltage testing, Wrindu has built strong relationships with grid utilities, OEMs, and industrial clients. Its reliable logistics and after-sales service simplify sourcing and integration for wholesalers looking to distribute premium-quality testing instruments nationwide.

How Does SFRA Fit into China’s Energy Equipment Market

In China’s growing energy and grid modernization sector, SFRA serves as a critical diagnostic tool for transformers and substations. It enables predictive maintenance and supports digital asset management systems. Wrindu’s SFRA products meet ISO9001, IEC, and CE certifications, aligning with domestic quality and safety goals. Their scalability—from single devices to multi-site deployments—makes them essential for utilities, renewable energy plants, and industrial power facilities.

How Can Wrindu Support OEM and Private-Label Cooperation

Wrindu partners with OEMs and private-label clients to create tailored SFRA configurations and integrated testing stations. Its engineering team collaborates on design, software customization, and test bench compatibility to suit specific voltage levels and transformer types. Local manufacturing, training, and after-sales services ensure shorter development cycles and faster product launches. This cooperative model enhances brand value and strengthens long-term OEM partnerships in China’s competitive manufacturing ecosystem.

| Implementation Step | Description |

|---|---|

| 1. Assessment | Define transformer specifications and test goals |

| 2. Integration Planning | Align with QA systems and data reporting |

| 3. Installation & Training | Deploy hardware and train operators |

| 4. Pilot Phase | Validate procedures and performance |

| 5. Full Rollout | Scale across production lines |

How Can Wrindu SFRA Be Deployed in a Chinese Factory

The implementation process begins by assessing transformer types and production needs. Integration planning ensures compatibility with existing QA and data management systems. Wrindu assists with installation, calibration, and operator training for optimal setup. A pilot test phase validates results before full deployment. Continuous monitoring and Wrindu’s local technical support maintain long-term efficiency, ensuring stable operation and improved product reliability for large-scale manufacturing facilities.

Wrindu Expert Views

“Wrindu’s SFRA technology bridges precision testing with real-world usability. For Chinese manufacturers, its modular structure, intuitive software, and localized support simplify both operation and maintenance. By integrating Wrindu systems into production lines, factories achieve faster diagnostics, reduced downtime, and stronger quality assurance — key factors in maintaining global competitiveness.” — Wrindu Expert

Why Wrindu Remains a Trusted Partner for Chinese Manufacturers

Wrindu’s SFRA systems are designed for demanding OEM and wholesale environments, offering unmatched precision and durability. Certified under ISO9001, IEC, and CE, Wrindu’s products help manufacturers achieve compliance and efficiency. Its local service teams across China ensure fast technical response and training support. With Wrindu’s continuous innovation and dedication to customer success, Chinese producers can enhance QA accuracy, reduce repair costs, and accelerate export readiness.

Conclusion

Wrindu’s SFRA test equipment empowers Chinese OEMs, manufacturers, and wholesale suppliers to achieve accurate diagnostics, efficient maintenance, and consistent quality control. Combining advanced engineering, local service, and robust certifications, Wrindu enhances the performance and safety of electrical systems across China. Integrating Wrindu SFRA solutions ensures lower operational risk, improved productivity, and stronger market competitiveness in both domestic and international markets.

FAQs

How does Wrindu SFRA integrate with Chinese factory systems?

It connects seamlessly to existing QA dashboards and data management tools, supporting real-time monitoring and standardized testing routines.

Is Wrindu SFRA easy for technicians to maintain?

Yes, with modular construction, guided maintenance schedules, and accessible local service teams across China.

Can Wrindu provide customized SFRA models for OEMs?

Absolutely. Wrindu offers co-branded designs, tailored test ranges, and integration with private-label production lines.

What certifications ensure Wrindu SFRA product quality?

All SFRA systems meet ISO9001, IEC, and CE certification standards for safety and performance.

Where can wholesalers purchase Wrindu SFRA systems in China?

Through Wrindu’s authorized distribution network and regional sales offices serving key industrial zones nationwide.