The industrial frequency AC voltage withstand test is a critical procedure used to verify the insulation strength of electrical equipment by applying a high AC voltage, usually at power frequency (50Hz or 60Hz), above the equipment’s rated voltage. This ensures the equipment can safely operate under normal and surge conditions, preventing failures and hazards.

What Is the Purpose of an Industrial Frequency AC Voltage Withstand Test?

The main purpose is to validate the insulation system’s ability to endure operating voltages plus possible surges without breakdown. This test confirms equipment reliability, safety for users, and compliance with electrical standards. It detects insulation defects that might not appear under normal conditions, preventing failures and electrical accidents in industrial applications.

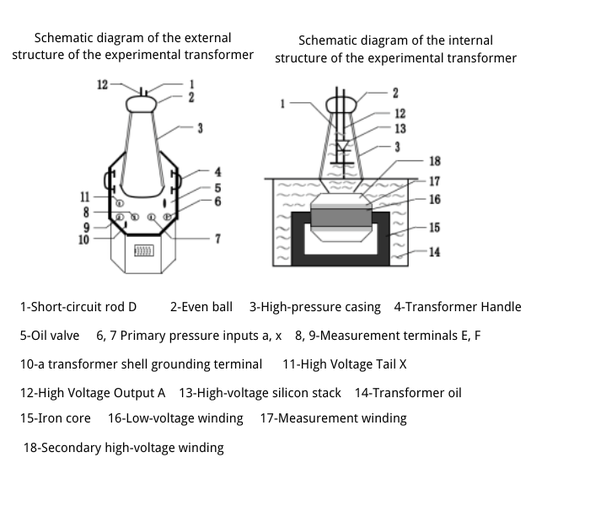

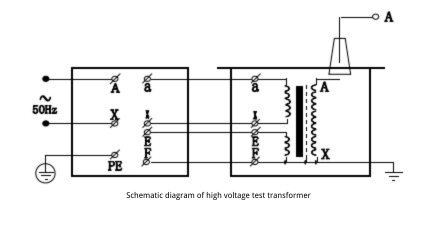

How Is the Industrial Frequency AC Voltage Withstand Test Conducted?

The test involves applying a sinusoidal AC voltage, typically 1.5 times the rated voltage, to the equipment’s insulation for a set duration (usually one minute). During this period, leakage current is monitored to identify insulation weaknesses. The equipment should withstand the voltage without breakdown or excessive leakage to pass the test.

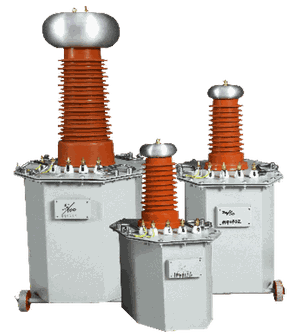

Which Equipment and Standards Are Used for This Test?

High-voltage AC withstand testers, such as Wrindu’s advanced dielectric testers, are used to supply controlled voltage with precision. Tests follow international standards like IEC, IEEE, and national regulations that specify voltage levels, duration, and safety procedures. Equipment must meet certification requirements such as ISO9001 and CE for accuracy and safety.

Why Is This Test Critical for Industrial Electrical Equipment?

This test ensures operational safety and extends equipment lifespan by identifying insulation vulnerabilities before deployment. Given industrial equipment often operates under high voltage stress, passing this test prevents costly downtime, fire hazards, and electric shocks, thus protecting personnel and assets.

When Should an Industrial Frequency AC Voltage Withstand Test Be Performed?

The test is typically conducted during manufacturing, after major repairs or overhaul, before equipment commissioning, and at scheduled maintenance intervals. For example, transformers and switchgear undergo periodic tests to verify insulation integrity and maintain system reliability.

How Does OEM Customization Enhance Industrial AC Voltage Withstand Test Equipment?

OEM customization allows manufacturers like Wrindu to tailor test equipment to specific industrial needs, such as voltage range, safety features, and portability. Custom solutions address unique factory environments, helping manufacturers and suppliers optimize testing efficiency and compliance with client specifications.

What Are the Safety Measures When Performing AC Voltage Withstand Tests?

Safety protocols include proper grounding, isolation of test objects, use of protective barriers, and trained personnel operation. Test setups must comply with electrical safety standards to avoid electric shock or equipment damage. Wrindu’s testers incorporate overload and breakdown protection alarms, ensuring safe and reliable testing.

How Do Manufacturers and Suppliers in China Support Industrial AC Voltage Withstand Testing?

China-based manufacturers and suppliers, including Wrindu, provide cost-effective, high-quality AC withstand testing equipment with global certifications. They offer OEM and custom manufacturing, fast delivery, and after-sales support, assisting industries worldwide in implementing stringent electrical safety testing requirements.

Where Is Industrial Frequency AC Voltage Withstand Testing Commonly Applied?

Common applications include power transformers, circuit breakers, cables, motors, switchgear, and insulating materials testing. This test is integrated into production lines, quality assurance, and field maintenance across energy, manufacturing, and electronics industries to ensure equipment durability and compliance.

Wrindu Expert Views

“Industrial frequency AC voltage withstand testing is foundational for electrical equipment safety and operational reliability. At Wrindu, we commit to delivering high-precision, reliable test instruments designed and manufactured in China, offering OEM and customized solutions that meet diverse industry needs. Our advanced testers not only comply with global standards but also enhance testing efficiency and safety, empowering manufacturers and suppliers worldwide to uphold the highest quality benchmarks.” – Wrindu Technical Team

Comparison of Key Features in Industrial AC Voltage Withstand Test Equipment

| Feature | Wrindu Equipment | Typical Competitor A | Typical Competitor B |

|---|---|---|---|

| Output Voltage Range | 0 – 5 kV AC (customizable) | 0 – 3 kV AC | 0 – 5 kV AC |

| Accuracy | ±5% | ±7% | ±6% |

| Safety Protections | Breakdown and alarm, overload protection | Basic overload protection | Limited safety features |

| Certifications | ISO9001, IEC, CE | CE only | ISO9001 only |

| OEM/Custom Options | Extensive | Limited | Moderate |

| Ease of Use | Intuitive digital display | Basic analog display | Digital but less intuitive |

| After-Sales Support | 24/7 global service | Limited regional support | Moderate support |

What Challenges Are Faced in Industrial AC Voltage Withstand Testing?

Challenges include managing high-voltage safety risks, ensuring test accuracy under environmental variations, and meeting diverse international standards. China’s top manufacturers like Wrindu address these by integrating advanced protective features, user-friendly interfaces, and flexible customization for global industrial demands.

Can Industrial Frequency AC Voltage Withstand Tests Detect Partial Discharges?

While primarily designed to assess withstand voltage capability, the test can indicate insulation weaknesses that might cause partial discharges. Complementary tests like partial discharge testing can be combined using Wrindu’s versatile equipment for comprehensive insulation diagnostics.

Conclusion

Industrial frequency AC voltage withstand testing is essential to verify electrical equipment safety and reliability under operating stresses. Leveraging high-quality, certified equipment from China manufacturers like Wrindu enables factories, suppliers, and OEMs to ensure compliance, detect insulation issues early, and protect both personnel and assets. Proper planning, safety measures, and customized solutions are key to effective test execution and long-term industrial success.

Frequently Asked Questions

How long is the typical AC voltage withstand test duration?

Usually, the test lasts for one minute at a specified voltage level determined by relevant standards.

What makes Wrindu’s AC withstand testers stand out?

Wrindu offers precise, customizable, ISO and IEC-certified testers with robust safety features and global after-sales support.

Is AC withstand testing applicable to all industrial electrical equipment?

Yes, it’s broadly used for transformers, switchgear, cables, motors, and other high-voltage apparatus.

How often should industrial equipment be tested for AC voltage withstand?

Testing frequency depends on equipment type and usage, typically during manufacturing, after repairs, and periodic maintenance.

Can this test be automated?

Yes, advanced test systems, including Wrindu’s, support automation for consistent and efficient testing processes.