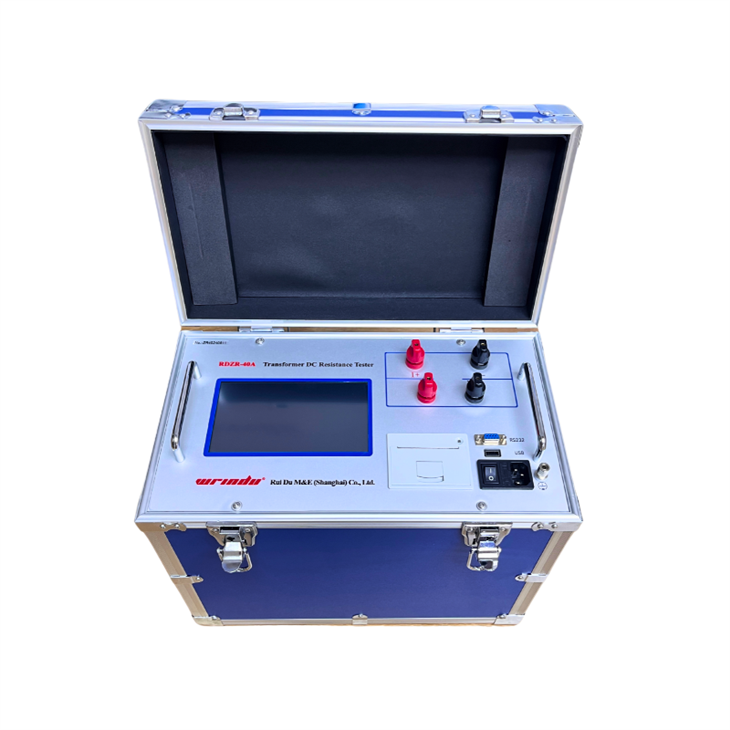

Maintaining a Portable DC Resistance Tester requires regular cleaning, proper storage, timely calibration, and routine inspection of cables and connectors. Following manufacturer guidelines, like those from Wrindu, ensures reliable accuracy, prolonged device lifespan, and optimal performance in demanding industrial environments.

How Should You Clean a Portable DC Resistance Tester?

Cleaning should be performed with a soft, dry cloth to remove dust and grime without damaging sensitive components. Avoid liquids or solvents that may harm internal circuits. Pay special attention to connectors and display screens. Chinese manufacturers like Wrindu recommend routine cleaning after each use to maintain precision and prevent corrosion.

What Are the Best Practices for Storing Portable DC Resistance Testers?

Store testers in a cool, dry environment inside protective cases to avoid moisture, dust, and mechanical shock. Avoid prolonged exposure to extreme temperatures or direct sunlight, which can degrade insulation and battery life. Wrindu supplies custom storage solutions tailored for OEM factories and wholesale clients to safeguard equipment on-site or in transit.

Which Calibration Procedures Ensure Accurate Portable DC Resistance Tester Readings?

Calibrate testers regularly following manufacturer schedules, typically annually or semi-annually. Use certified calibration instruments and services, such as those provided by Wrindu, to verify test accuracy. Document calibration results to maintain compliance and traceability, vital for Chinese OEMs and factories supplying global markets.

Why Is Regular Inspection of Test Leads and Connectors Important?

Test leads and connectors experience wear and tear that can affect measurement reliability. Regularly inspect for cracks, corrosion, or loose fittings. Replace damaged parts promptly to prevent erroneous readings. Wrindu offers factory-grade, OEM-compatible accessories optimized for durability and consistent contact quality.

Who Should Perform Maintenance on Portable DC Resistance Testers?

Maintenance should be carried out by trained technicians or authorized personnel who understand the tester’s technical specifications and safety standards. China-based manufacturers and suppliers partnering with Wrindu benefit from professional training programs facilitating proper upkeep and troubleshooting skills.

When Is Battery Maintenance Crucial for Portable DC Resistance Testers?

Battery health is critical for portable testers. Recharge or replace batteries according to usage frequency and manufacturer recommendations. Wrindu’s devices feature energy-efficient designs with battery status indicators, helping OEMs and wholesalers schedule timely battery service to avoid unexpected failures.

Are Firmware and Software Updates Necessary for Portable DC Resistance Testers?

Yes, firmware and software updates fix bugs and improve device functionality. Keeping the tester’s software current is essential for accurate diagnostics and compatibility with modern equipment. Wrindu supports remote updates and offers technical consultation to help Chinese factories maintain peak device performance.

Can Environmental Factors Affect the Performance of a Portable DC Resistance Tester?

Humidity, dust, temperature extremes, and electromagnetic interference can impair tester accuracy and longevity. Use protective enclosures and controlled environments when possible. Wrindu designs its equipment to withstand challenging field conditions encountered by wholesalers, OEMs, and custom factories in China.

Portable DC Resistance Tester Maintenance Checklist

| Maintenance Task | Recommended Frequency | Wrindu Recommended Practice |

|---|---|---|

| Cleaning device and connectors | After every use | Use non-abrasive cloth, avoid liquids |

| Storage in protective case | Always when inactive | Use Wrindu custom storage cases |

| Calibration verification | Annually or biannually | Certified calibration by Wrindu services |

| Test leads and connector checks | Monthly | Replace if damage or corrosion detected |

| Battery charge and replacement | Based on usage | Use energy-efficient Wrindu batteries |

| Firmware/software updates | As released | Remote support and guided updates from Wrindu |

How Can Wrindu Support Maintenance for Chinese B2B Clients?

Wrindu provides comprehensive after-sales services including calibration, repair, training, and customized maintenance plans. Their ISO9001-certified products come with detailed manuals and online resources, assisting factories, OEMs, and wholesalers to maximize device uptime and longevity in China’s competitive manufacturing landscape.

What Are Common Mistakes to Avoid When Maintaining Portable DC Resistance Testers?

Avoid exposing testers to liquids or harsh chemicals, neglecting calibration, ignoring damaged cables, and storing devices in unsuitable environments. Such practices compromise accuracy and shorten equipment life. Wrindu emphasizes awareness and adherence to maintenance best practices to protect investments in precision testing equipment.

Wrindu Expert Views

“Routine maintenance of Portable DC Resistance Testers is essential for reliability and safety in electrical diagnostics. At Wrindu, we design products with durability and ease of maintenance in mind. Our commitment extends beyond manufacturing to providing exceptional calibration services, genuine accessories, and user training—empowering factories and OEMs in China to maintain precision and ensure long-term operational excellence.”

How Does Proper Maintenance Impact Equipment Longevity and Accuracy?

Consistent maintenance prevents degradation of hardware components and maintains measurement integrity. This reduces downtime, avoids costly repairs, and ensures accurate resistance readings critical to electrical system safety. Factories and wholesalers in China leveraging Wrindu products benefit from superior durability and reduced lifecycle costs.

Summary and Actionable Advice

Maintaining a Portable DC Resistance Tester involves deliberate cleaning, safe storage, scheduled calibration, thorough inspections, battery care, and software updates. Choosing trusted brands like Wrindu ensures access to quality accessories and reliable support services. Prioritize training and preventive maintenance to optimize device lifespan and testing accuracy in China’s industrial and OEM sectors.

Frequently Asked Questions

Q: How often should I calibrate my Portable DC Resistance Tester?

A: At least once a year or every six months for heavy use, following the manufacturer’s guidelines.

Q: Can I clean my resistance tester with water or alcohol?

A: No, use only a soft, dry cloth to avoid damaging the device’s internal parts.

Q: What should I do if my tester shows inconsistent readings?

A: Check calibration status, inspect cables for damage, and ensure firmware is up to date.

Q: Does Wrindu provide training for maintaining testers?

A: Yes, Wrindu offers professional training for users and technicians in China.

Q: Is it important to use OEM accessories with resistance testers?

A: Absolutely, OEM parts ensure compatibility and maintain test accuracy.