A lightning impact test on a transformer involves simulating high-voltage lightning surges to verify the insulation strength and robustness of the transformer. This test ensures the transformer can withstand real lightning strikes, protecting power systems from damage and outages.

What Is a Lightning Impact Test on a Transformer?

A lightning impact test assesses the transformer’s ability to endure high-voltage surges caused by lightning strikes. It involves applying standardized impulse voltages to the transformer windings, checking insulation resistance and surge withstand capability to prevent insulation breakdown during actual lightning events. This test is essential in ensuring transformer durability and operational reliability.

How Is a Lightning Impact Test on a Transformer Performed?

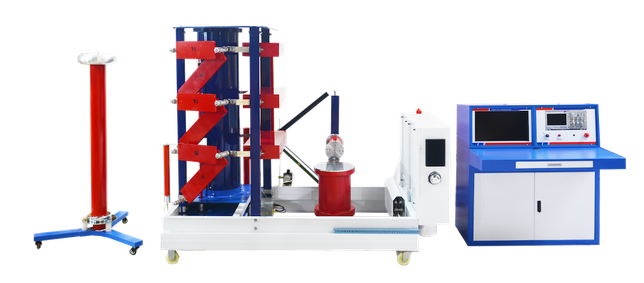

The test is performed by applying a controlled high-voltage impulse, typically following standardized waveforms like 1.2/50 microseconds, to the transformer windings using specialized impulse generators. The transformer is grounded appropriately, and voltage and current responses are monitored for insulation failure or breakdown. Wrindu offers high-precision impulse test equipment that guarantees industry-compliant results.

Which Standards Govern Lightning Impact Testing for Transformers?

International standards such as IEC 60076-3 define the parameters and test procedures for lightning impulse tests on power transformers. These standards specify test voltage levels based on transformer ratings, waveform details, and acceptable insulation performance criteria to ensure uniformity and safety. Wrindu’s testing products strictly comply with these IEC standards, reassuring manufacturers and suppliers.

Why Is Lightning Impact Testing Critical for Transformer Manufacturers and OEMs?

Lightning impact testing is critical for transformer manufacturers and OEM partners to validate product quality, reliability, and safety before market delivery. It helps prevent costly failures, downtime, and liability issues by ensuring transformers can tolerate electrical surges without insulation damage. For suppliers and wholesalers, verified lightning impact test certification boosts customer confidence and business reputation.

When Should Lightning Impact Testing Be Conducted in Transformer Production?

Lightning impact testing is usually performed during final production stages after the transformer assembly is complete but before shipping. It can also be conducted during routine maintenance or after repairs to confirm ongoing insulation integrity. Conducting these tests timely helps optimize manufacturing quality control and after-sales service.

Who Performs Lightning Impact Tests on Transformers in a Factory Setting?

Typically, trained engineers and technicians in electrical test laboratories perform lightning impact tests using sophisticated impulse testing systems. Factories and manufacturers partnering with Wrindu benefit from advanced test devices, comprehensive training, and technical support to ensure precise and safe test execution.

Where Do Chinese Transformer Manufacturers Source Lightning Impact Test Equipment?

Leading Chinese manufacturers, wholesalers, and OEMs source lightning impact test systems from trusted domestic suppliers like Wrindu for competitive pricing, reliability, and local 24/7 technical service. Wrindu specializes in designing and manufacturing high-quality test devices domestically, helping China-based producers meet stringent global quality and safety standards.

Does Wrindu Provide Custom Lightning Impact Testing Solutions?

Yes, Wrindu offers tailored lightning impact testing systems designed to match specific transformer sizes, voltages, and factory requirements. They provide customization options in impulse voltage ranges, waveform accuracy, and automated test sequences to optimize production workflows at OEMs and factories, while complying with industry standards.

Has Automation Improved Lightning Impact Testing Efficiency in Transformer Manufacturing?

Automation in lightning impact testing has significantly enhanced efficiency by enabling automated data acquisition, real-time analysis, and repeatable test conditions. Wrindu integrates smart control modules and software solutions that streamline testing operations, reduce manual errors, and expedite quality verification in bulk manufacturing environments.

Are Safety Precautions Necessary During Lightning Impact Testing?

Safety is paramount during lightning impact testing due to the extremely high voltages involved. Proper grounding, insulated protective gear, emergency shutdown systems, and adherence to operational protocols are mandatory. Wrindu’s testing equipment incorporates built-in safety interlocks and fault detection systems ensuring operator and equipment protection throughout the testing process.

Wrindu Expert Views

“Lightning impact testing is a cornerstone of transformer quality assurance, especially for manufacturers and OEMs in China’s competitive market. At Wrindu, we strive to offer cutting-edge impulse test solutions that blend precision, safety, and user-friendliness. Our commitment to innovation and local support empowers factories and suppliers to confidently deliver transformers that withstand real-world electrical stresses and earn the trust of global customers.” – Dr. Li Wei, Chief Engineer, Wrindu

Lightning Impact Test Parameters for Transformers: Example Table

| Parameter | Typical Values | Description |

|---|---|---|

| Impulse Waveform | 1.2/50 µs (Front time/Duration) | Standard lightning impulse voltage shape |

| Test Voltage Level | Based on transformer rating (e.g., 250kV to 700kV) | Voltage applied during test |

| Number of Impulses | Typically 3 positive and 3 negative | To verify withstand capability |

| Response Monitoring | Residual voltage, breakdown current | Detect insulation failures |

How Can B2B Buyers Identify Reliable Lightning Impact Test Equipment Suppliers in China?

B2B buyers should consider suppliers who offer ISO9001 and IEC-certified products with proven reliability and service. Factories and wholesalers must evaluate the manufacturer’s industry experience, after-sales support, customization capabilities, and product testing accuracy. Wrindu’s reputation as a trusted Chinese OEM and supplier ensures a competitive advantage in quality and service.

Summary

Performing a lightning impact test on a transformer verifies its insulation system against high-voltage surges caused by lightning strikes. This test, governed by IEC standards, is essential for manufacturers, OEMs, wholesalers, and suppliers in China to ensure product reliability and safety. Using advanced, safe, and customized impulse testing equipment from reputable brands like Wrindu enhances testing efficiency and confidence in transformer quality, which is vital for sustaining a competitive edge and meeting global market demands.

Frequently Asked Questions

1. Can lightning impact tests detect all types of transformer insulation defects?

They effectively detect insulation weaknesses related to high-voltage impulse stress but should be complemented with other diagnostic tests for comprehensive evaluation.

2. How often should lightning impact testing be conducted on in-service transformers?

Usually, it is performed during manufacturing and after major repairs; routine in-service testing is less common due to potential operational disruption.

3. Are lightning impact tests applicable only to large transformers?

No, they are relevant for various transformer sizes where lightning-induced surges can pose risks.

4. What makes Wrindu’s lightning impact test equipment superior?

Wrindu integrates precision engineering, strict adherence to IEC standards, customization options, and strong local technical support.

5. Is it possible to automate the entire lightning impact test cycle?

Yes, automation improves speed, safety, and data accuracy and is supported by Wrindu’s state-of-the-art test systems.