High voltage insulation withstand test

RuiDu Mechanical: Your Reliable High Voltage Insulation Test Equipment Supplier!

RuiDu Mechanical and Electrical (Shanghai) Co., Ltd. is a leading global power testing equipment manufacturer and system solution provider. Our company was established in 2014. Our main products are substation transformers, high-voltage switches, transformers, lightning arresters, batteries, cable faults, relay protection, insulation withstand voltage, transformer oil injection equipment, etc. Our factory covering an area of more than 50,000 square meters, 6 product production lines and more than 200 employees, selling the products to more than 120 countries and regions. In addition, we support high-volume production, calibrate and test instruments at the point of sale, providing repair instructions for these products.

Rich Experienced

Our team has more than 10 years of experience in the industry, providing customers with compliant, high-quality equipment, and developing friendly cooperation with partners such as Kenya Power, UETCL, TCN, EVN, PLN, NGCP, CFE.

Wide Product Range

Our broad product offering includes digital multimeters, power analyzers, thermal imaging cameras, insulation resistance testers, accessories and integrated test tools. These test devices can be easily integrated into a variety of electrical and electromechanical systems.

Guaranteed Quality

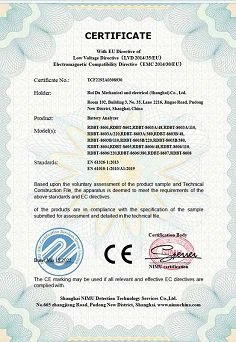

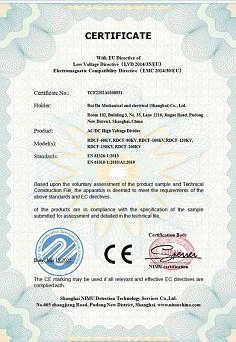

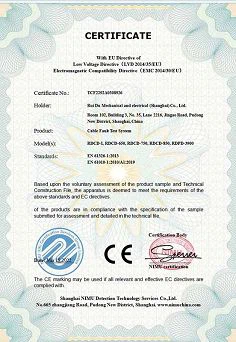

Our production workshops are professionally assessed, developed and validated, equipped with a range of analytical instruments and all products have international ISO 9000 series, IEC and CE certifications.

Customized Service

According to your usage needs, our team is online 24/7 to provide you with detailed consultation and after-sales service, and provide OEM and ODM customized products.

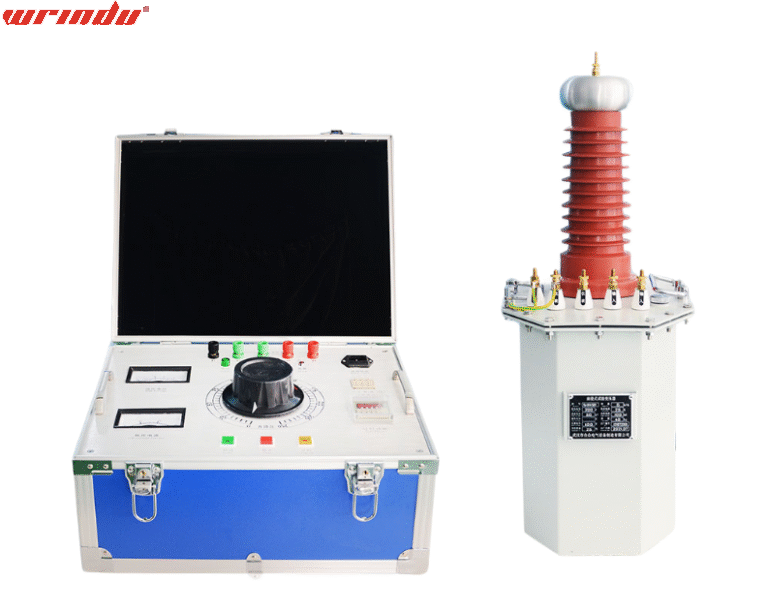

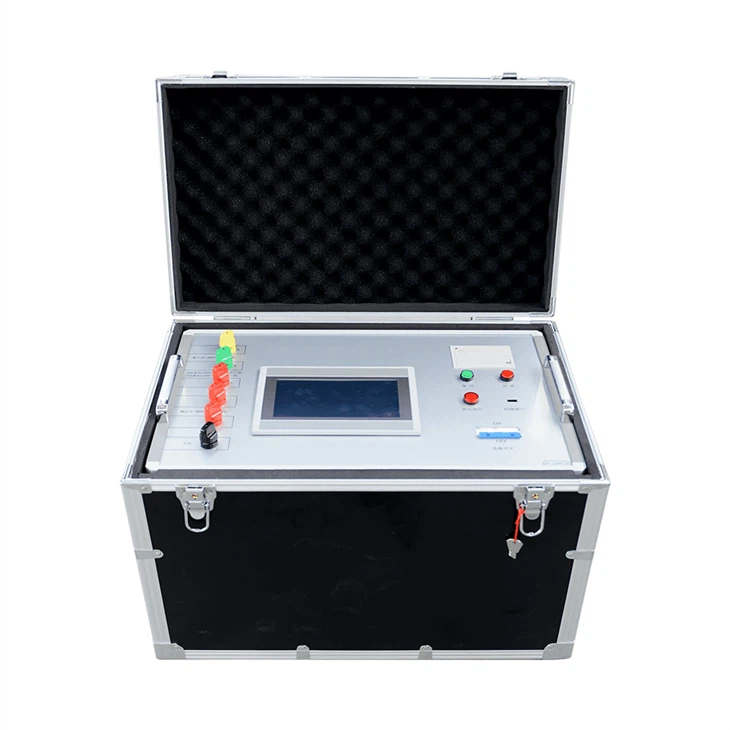

What is High Voltage Insulation Test Equipment?

High voltage insulation test equipments measure the insulation resistance of electrical systems and equipment. These test equipments use a high voltage, low current DC charge to measure the resistance within wires and motor windings to identify current leakage and faulty or damaged insulation, which can lead to arc faults, blown circuits, and risk of electrical shock or fire. Their voltage can range from a few hundred volts to several thousand, making them versatile for various electrical systems, which helps to prevent the occurrence of electric shock and equipment damage.

Features of High Voltage Insulation Test Equipment

Intelligent Computing

Our high voltage insulation testers can automatically calculate Polarization Index (PI) and Dielectric Absorption Ratio (DAR) to perform up to 1,300 measurements at 2,500 V or 6,500 measurements at 250 V for increased efficiency.

Security Function

These testers are equipped with an IV 600V rating and a built-in voltage alarm function that sounds an alarm when a fault in the electrical system is detected, increasing safety during operation.

Stable Measurement

They adjust the test voltage from 250 V to 2500 V in 100 V increments, enabling faster and more stable insulation resistance measurements with short-circuit currents up to 5mA.

Convenience Display

Via visual or audible indicators on the screen display. These high voltage insulation testers verify data continuity so you can focus on the testing process rather than looking at the display.

Application of High Voltage Insulation Test Equipment

Preventive Maintenance

Insulation testers assess the integrity of electrical insulation by measuring resistance. This measurement is crucial because it can reveal the gradual degradation of insulation, which is not always apparent through visual inspection. By detecting deteriorating insulation, these testers help prevent short circuits, electrical leaks, and potential fire hazards.

Quality Assurance

High voltage insulation testers ensures compliance with safety standards in the manufacturing and assembly of electrical components. Every electrical product, from household appliances to industrial machinery, must adhere to stringent safety regulations, and insulation integrity is a key parameter in these standards. During manufacturing, a 5kV insulation tester is used to verify that each product meets the required insulation resistance levels.

Fault Diagnosis

When diagnosing faults in electrical systems, faults are often attributed to insulation failure – a common issue that can lead to severe consequences like equipment damage, power outages, and safety hazards. When a fault occurs, technicians use insulation testers to diagnose it comprehensively. These testers facilitate quick and accurate repairs by pinpointing the exact location and nature of the insulation breakdown.

Different Methods of HV Insulation Testing

AC tests are the most common type of high voltage tests for electrical engineering. They involve applying an alternating current (AC) voltage of a specified frequency, magnitude, and duration to the equipment under test. The purpose of AC tests is to verify the withstand capability and the dielectric strength of the insulation. AC tests can be divided into two categories: power frequency tests and lightning impulse tests. Power frequency tests use a sinusoidal voltage of 50 or 60 Hz, depending on the system frequency, and are used to check the steady-state behavior of the insulation. Lightning impulse tests use a voltage waveform that mimics the shape and duration of a lightning strike, and are used to check the transient behavior of the insulation.

DC tests are another type of high voltage tests for electrical engineering. They involve applying a direct current (DC) voltage of a specified polarity, magnitude, and duration to the equipment under test. The purpose of DC tests is to measure the insulation resistance, the leakage current, and the polarization index of the insulation. DC tests can be used to detect defects, such as cracks, voids, and moisture, in the insulation. DC tests can also be used to assess the aging and deterioration of the insulation over time.

DC High voltage test generally called Hi-pot test are application of DC High voltage according to operating volatge of equipment. This test detoriates the insulation and shall not be used as extensive tests. It is generally used while erection of the electrical aapartus.

PD tests are a special type of high voltage tests for electrical engineering. They involve measuring the partial discharge (PD) activity in the insulation under a high voltage stress. PD is a phenomenon that occurs when the electric field in the insulation exceeds a critical value, causing small sparks or corona discharges in the gaps or defects. PD can cause degradation and damage to the insulation over time, leading to breakdown and failure. PD tests can be used to monitor the condition and quality of the insulation, and to identify the location and severity of the defects.

VLF tests are a relatively new type of high voltage tests for electrical engineering. They involve applying a very low frequency (VLF) voltage of 0.01 to 0.1 Hz to the equipment under test. The purpose of VLF tests is to test the insulation of long cables and transformers that are difficult or impractical to test with AC or DC voltages. VLF tests can reduce the test time, the test voltage, and the power requirements compared to AC or DC tests. VLF tests can also detect defects that may not be revealed by AC or DC tests.

RIV tests are another special type of high voltage tests for electrical engineering. They involve measuring the radio interference voltage (RIV) generated by the equipment under test under a high voltage stress. RIV is a measure of the electromagnetic noise or interference that can affect the communication and signal transmission systems in the vicinity of the equipment. RIV tests can be used to evaluate the performance and compliance of the equipment with respect to the standards and regulations for radio interference.

HVDC tests are a type of high voltage tests for electrical engineering that are specific to high voltage direct current (HVDC) systems. HVDC systems are used to transmit large amounts of power over long distances with minimal losses and better control. HVDC tests involve applying a DC voltage of a specified polarity, magnitude, and duration to the HVDC equipment under test. The purpose of HVDC tests is to verify the design, operation, and protection of the HVDC equipment, such as converters, cables, filters, and valves. HVDC tests can also be used to simulate the effects of faults, switching, and polarity reversal on the HVDC equipment.

Factors to Consider When Choose High Voltage Insulation Test Equipment

Test Voltage

If you’re an electrician – only interested in installation testing – you probably only need a single voltage. Whereas, if you’re more of a repair and maintenance technician, you’re likely going to want an instrument with diagnostic capabilities that can compare various tests at different voltages. Right? You should also base your voltage requirements on the rated voltage of the equipment you are working with, specifically whether or not you will be performing tests at or above rated, i.e. stress tests.

Something to keep in mind is that pervasive insulation damage, such as moisture ingress, is revealed at any voltage; whereas mechanical damage usually requires a higher voltage for detection – capable of arcing an air gap.

With 1 kV, 2.5 kV, and 5 kV models to choose from, this may be the most critical decision you have to make. But keeping our above advice in mind, you’re well on your way to finding your forever.

Measurement Range

Unfortunately, you’re not done yet, not even close. If you’re an electrician or repairman – primarily interested in proofing – you can get away with an instrument that provides infinity readings, since you are just concerned with meeting or exceeding a certain resistance, rather than knowing the specific measurement. It’s more of a pass or fail ordeal.

However, if you are working in the realm of predictive maintenance, it’s critical to know exactly how your measurements change over time, specifically in the upper values of resistance. Thanks to recent technology upgrades, certain instruments allow you to test into the tera ohm range (TΩ) – giving you the capability to differentiate between elevated resistance measurements over time.

Power Source

The test is the same, regardless of the power source you’re using. At the end of the day, it comes down to this: alkaline batteries (like AA), hand-cranks, and rechargeable batteries can all deliver the same level of voltage you’re looking for – even 1,000 volts, believe it or not. Like anything, there are advantages and disadvantages to each.

Voltage Detection

Each of our models will detect unwanted voltage on the item under test, which is great. It’s up to you though, whether you want an audible warning signal or a visual display on the monitor.

Display

That bring us nicely to the next feature under consideration – display. Digital or analog? Again, it’s largely a question of personal preference. If you’re truly indecisive, some newer models combine both capabilities in a single unit, so look out for those.

Ω/kΩ Ranges

Okay, these are commonly referred to as “continuity” and “resistance” ranges, which greatly enhance the depth of your testing capabilities. If you’re looking at two (or more) testers with similar functions, the Ω/kΩ ranges can help you differentiate between the two and solidify your decision. Ohm ranges can help you verify the integrity of circuits and connections, while kilohm ranges are helpful for identifying areas of insulation deterioration.

Guard Terminal

If you want to eliminate certain components of leakage from your measurements, you should take the guard terminal into consideration. While electricians likely don’t need this third terminal, maintenance personnel should, and repairmen definitely will.

Price

From a few hundred to several thousand dollars, we have an insulation tester for every budget. Don’t let the price tag fool you either. Regardless of your budget, you’ll find a model that not only fits your testing requirements, but also offers a range of additional features too.

“Extra” Features

Please keep the following statement in mind when you are selecting a tester. From one model to the next, the accuracy and reliability of measurements never changes; it’s the additional capabilities and testing flexibility that changes between units.

Newer models offer pre-programmed standardized tests, such as Polarization Index, Step Voltage, and Dielectric Discharge, along with calculation and storage of results, downloading capabilities, timed tests, leakage current measurements, and a “burn mode”.

How to Use High Voltage Insulation Test Equipment?

Personal Safety

●Wear Protective Gear: Personal protective equipment (PPE) is essential when dealing with high-voltage equipment. Key items include:

●Insulating Gloves: To protect against electric shocks.

●Safety Goggles: To shield the eyes from electrical arcs and debris.

●Flame-Resistant Clothing: To minimize the risk of burns from potential electrical fires.

●Work in Teams: Whenever possible, conduct testing with a partner. In case of an emergency, having someone on hand can make a significant difference.

●Stay Alert: Always be conscious of your surroundings. Be aware of potential hazards in the work area, such as wet surfaces or exposed wiring.

Guidelines

●Read the Manual: Before using an insulation tester, thoroughly read and understand the manual. Different models may have unique features or safety precautions.

●Understand the Ratings: Be aware of the voltage ratings of the tester and the tested system. Using a tester on a system that exceeds its rated capacity can be dangerous.

●Follow Procedures: Adhere to standard operating procedures for insulation testing. This includes ensuring the equipment being tested is de-energized and properly grounded.

●Be Aware of Environmental Factors: Environmental conditions such as moisture, temperature, and flammable materials can affect the safety and accuracy of insulation testing.

Calibration and Maintenance

●Routine Calibration: Regular calibration ensures the tester provides accurate readings, crucial for identifying potential hazards. Calibration should be performed according to the manufacturer’s guidelines.

●Regular Maintenance Checks: Perform regular checks on the tester for signs of wear and tear, especially on the cables and probes. Damaged equipment can be a significant safety risk.

●Keep Records of Maintenance and Calibration: Maintain a log of all maintenance and calibration activities. This not only helps in keeping track of the health of your tester but also in planning future maintenance schedules.

●Update Software: Ensure the software is regularly updated for testers with software components. This can enhance the functionality and safety features of the tester.

●Handle Batteries with Care: For testers powered by batteries, handle and store the batteries properly. Faulty batteries can cause inaccurate readings and pose safety risks.

Additional Considerations

●Stay Informed: Keep up-to-date with the industry’s latest safety standards and practices.

●Emergency Procedures: Be prepared with a clear plan for emergencies. This includes knowing the location of emergency equipment and having a clear evacuation route.

●Training and Education: Regular training sessions should be conducted for all personnel using the testers. These sessions should cover both operational and safety aspects.

Certificate Photo

Factory Photo

FAQ

Q: What is high voltage insulation tester?

A: A high voltage digital insulation tester is a specialized device used to measure the insulation resistance of electrical equipment and systems. It is designed to ensure the safety and reliability of electrical installations by detecting any insulation faults or weaknesses.

Q: What is the difference between a high voltage test and a Megger test?

A: Both instruments apply a comparatively high voltage across insulation and draw leakage current through the insulation, commensurate with its insulating properties and condition. But, a megohmmeter gives the operator a measurement, while a high-pot takes action.

Q: What is the reason to use higher voltages to measure insulation?

A: Insulation resistance must be checked by applying appliances or installations a higher voltage than its normal working voltage, because an insulation resistance is lower at higher voltage than at lower voltage.

Q: What is the difference between high voltage test and insulation test?

A: In summary, insulation tests primarily measure resistance in insulating materials, while dielectric tests focus on the ability of those materials to withstand high voltages without breaking down. Both tests are crucial for ensuring the safety and reliability of electrical systems.

Q: What is difference between HV test and insulation resistance test?

A: In principle, the high-voltage test is performed at the same connections as at the insulation-resistance test. In contrary to the insulation-resistance test, however, the high-voltage test is performed with much higher test voltages. The test voltage can be both AC and DC.

Q: What are the requirements for high voltage insulation?

A: The ideal insulation for higher voltage systems in aero- space applications should be light, chemically stable, and a good corona suppressor. It should withstand high voltages, have low dielectric loss, and have good thermal conductivity. If possible, it should be self-healing in case of electrical dis- charges.

Q: What is the difference between a megohmmeter and an insulation tester?

A: Some insulation testers also have built-in safety features, such as auto discharge of residual voltage after the test, to ensure operator safety. Megohmmeters, on the other hand, typically have simpler displays and features, focusing on basic insulation resistance measurements.

Q: What voltage should you do an insulation test?

A: The objective is to stress the insulation but not to over-stress it. When in doubt, use a lower test voltage. It’s usually appropriate to test insulation at twice the voltage it normally sees: for example 460 V to 600 V rated equipment is often tested at 1000 V.

Q: How do you test high voltage insulators?

A: Testing insulation involves applying a high voltage to the insulation and measuring the current, resistance, capacitance, or impedance. One of the most common methods is the megger test, which uses a handheld device called a megohmmeter or megger to generate DC voltage up to 15 kV.

Q: What is the standard for high voltage insulation resistance?

A: Insulation resistance should be approximately one megohm for each 1,000 volts of operating voltage, with a minimum value of one megohm. For example, a motor rated at 2,400 volts should have a minimum insulation resistance of 2.4 megohms.

Q: What is the best insulator for high voltage?

A: Insulators used for high-voltage power transmission are made from glass, porcelain or composite polymer materials. Porcelain insulators are made from clay, quartz or alumina and feldspar, and are covered with a smooth glaze to shed water.

Q: What is the minimum insulation resistance for high voltage equipment?

A: The rule states that insulation resistance should be approximately one megohm for each 1000 volts of operating voltage, with a one megohm minimum. (By following this rule, a motor rated at 2400 volts should have a minimum insulation resistance of 2.4 megohms).

Q: What are the materials used in high voltage insulation?

Electrical Insulator Materials & High Voltage Insulation Tape.

High Voltage Insulation Materials.

Battery Insulation.

Spiral Wound Tubing.

High Temperature Wire & Cable.

Thermal Insulation.

Polyshrink Film.

Q: What three tests are done for insulation resistance?

A: There are three commonly used methods for testing insulation resistance: spot reading test, time resistance test, and step voltage test. These three tests are used primarily to test insulation in motors, generators, cables, transformers, and other electrical apparatus.

Q: What are the two methods of insulation resistance testing?

A: In this article, we discuss three commonly used methods for testing insulation resistance: the Spot Reading test, the Time Resistance test, and the Step Voltage test. These three tests are used primarily to test motor, generator, cable, and transformer insulation.

Q: What is one of the most common insulation testers?

A: Megohmmeters provide a quick and easy way to determine the condition of the insulation on wire, generators, and motor windings. A megohmmeter is an electric meter that measures very high resistance values by sending a high voltage signal into the object being tested.

Q: How much voltage does a megger put out?

Q: Can a multimeter be used as a megger?

A: No you don’t. Megger generally produces 500_1000v DC accross it’s terminals & then detects the leakage current accross testing probes. While multimeters are made for measurement only and do not generate such high voltages.

Q: Why high voltages are required for insulation testing?

A: Insulation resistance must be checked by applying appliances or installations a higher voltage than its normal working voltage, because an insulation resistance is lower at higher voltage than at lower voltage.

Q: What is the role of insulation resistance on high voltage equipment?

A: Insulators help resist shock and short circuits, making electrical insulation one of the most critical components in any building or system. This also means that measuring resistance is especially important, and you must have a clear understanding of the resistance levels to take adequate precautions.