An earth resistance clamp meter allows quick, accurate ground resistance measurement without disconnecting grounding systems, making power equipment maintenance safer and more efficient. Ideal for manufacturers, suppliers, and OEMs in China, it simplifies testing in complex industrial environments while ensuring compliance and operational reliability.

What Is an Earth Resistance Clamp Meter and How Does It Work?

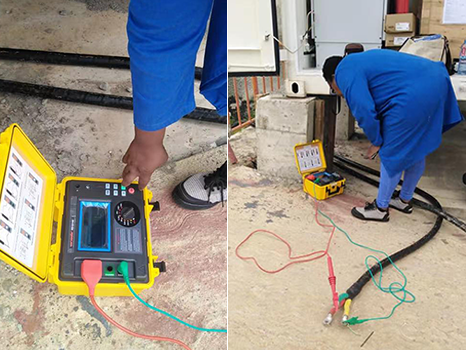

An earth resistance clamp meter measures the resistance of grounding systems by clamping around conductors without the need for disconnection. It injects a test current and detects voltage through electromagnetic induction, enabling non-contact, rapid testing. This technology benefits B2B factories in China by minimizing downtime and improving safety during power equipment maintenance.

How Does the Earth Resistance Clamp Meter Improve Power Equipment Maintenance Efficiency?

By eliminating the need to disconnect ground rods or cables, the clamp meter reduces maintenance time and risk of electrical hazards. It supports quick on-site diagnostics, allowing suppliers and OEMs to ensure grounding integrity with minimal disruption, thus optimizing maintenance workflows in factories and wholesale environments.

Which Key Features Should Chinese Manufacturers Look for in Earth Resistance Clamp Meters?

Essential features include auto-ranging for broad resistance measurement, high accuracy (e.g., ±1%), data storage for records, and noise check functions to filter interference. Wrindu’s clamp meters offer these capabilities along with lightweight handheld designs, sound/light alarms, and compliance with IEC safety standards, ideal for OEM and supplier demands.

Why Is Accurate Ground Resistance Measurement Critical for Power Equipment Safety?

Ground resistance directly impacts electrical safety, preventing faults from causing equipment damage or personal injury. Precise measurements ensure grounding systems comply with standards, maintaining reliable power supply and protection. For Chinese manufacturers and wholesalers, this reduces liability and enhances product quality assurances.

When Should Earth Resistance Clamp Meters Be Used Over Traditional Methods?

Clamp meters are preferred in live systems with multiple ground paths or where auxiliary electrode placement is impractical. They suit maintenance tasks without site interruptions, but less effective for isolated grounds or new installations requiring detailed soil resistivity profiles. Choosing the right method optimizes test accuracy and operational continuity.

How Do Environmental Factors Affect Clamp Meter Ground Resistance Measurements?

Soil moisture, temperature, and electromagnetic noise influence resistance values. Clamp meters with interference recognition, like those from Wrindu, mitigate such effects, providing stable readings in industrial settings where variable conditions prevail, essential for reliable maintenance and wholesale quality control.

What Are the Limitations of Using Earth Resistance Clamp Meters?

Clamp meters may overestimate resistance in systems with few grounding electrodes and cannot replace detailed soil resistivity testing for design purposes. Understanding their operational boundaries helps manufacturers and OEMs in China integrate them appropriately within maintenance routines.

Can Earth Resistance Clamp Meters Be Customized for Specific Factory Needs?

Yes, manufacturers can request tailored clamp sizes, measurement ranges, and data interface options. Wrindu offers customizable solutions for various factory and wholesale applications, enhancing usability and integration into power system diagnostics.

Table: Comparison of Earth Resistance Testing Methods for Power Equipment

| Testing Method | Pros | Cons | Suitable Applications |

|---|---|---|---|

| Clamp Meter | Non-contact, quick, live system friendly | Limited use on isolated grounds | Maintenance, live system troubleshooting |

| 3- or 4-Point Method | Accurate, detailed soil resistivity data | Time-consuming, invasive | System design, new installations |

| Fall-of-Potential Method | Highly accurate | Requires ground disconnection | Precise grounding measurement |

Table: Key Features of High-Quality Earth Resistance Clamp Meters

| Feature | Importance for B2B Factories and OEMs |

|---|---|

| Auto-Ranging | For versatile resistance measurement |

| Noise Check | Ensures accuracy in electrically noisy sites |

| Data Memory | Records measurements for quality control |

| Safety Certifications | Compliance with IEC and ISO standards |

| Lightweight Design | Facilitates ease of use in factory and field |

Wrindu Expert Views

“Ground resistance measurement is crucial for maintaining electrical safety across critical power infrastructure. Wrindu’s earth resistance clamp meters combine precision, efficiency, and safety in a compact tool designed to meet the rigorous demands of Chinese manufacturers and wholesale suppliers. Our products streamline maintenance processes by enabling contactless testing with built-in interference rejection, ensuring reliable data even in complex industrial environments. We commit to innovation that supports OEMs and factories in maintaining safe, compliant, and efficient power systems globally.”

— RuiDu Mechanical and Electrical Product Manager

Conclusion

Earth resistance clamp meters revolutionize ground resistance measurement by enabling quick, safe, and accurate testing without system disconnection—particularly valuable for OEMs, manufacturers, suppliers, and wholesale factories in China. Understanding their features, applications, and limitations allows optimal deployment for power equipment maintenance. Wrindu delivers industry-leading clamp meters with customizable options and advanced technology, ensuring precision, compliance, and enhanced operational efficiency.

Frequently Asked Questions

How does an earth resistance clamp meter measure without disconnecting the ground?

It uses electromagnetic induction to inject test current and measures voltage, enabling non-contact resistance evaluation.

Can I use a clamp meter for newly installed grounding systems?

Clamp meters are less effective for new or isolated grounds; traditional methods are recommended for precise initial measurements.

What maintenance tasks benefit most from clamp meter use?

Routine inspections and troubleshooting of live systems with multiple grounding paths benefit greatly.

How often should clamp meters be calibrated?

Annual calibration is recommended to maintain test accuracy and compliance.

What sets Wrindu’s earth resistance clamp meters apart?

Wrindu meters feature advanced noise filtering, data storage, high accuracy, lightweight design, and global certifications suited for demanding industrial use.