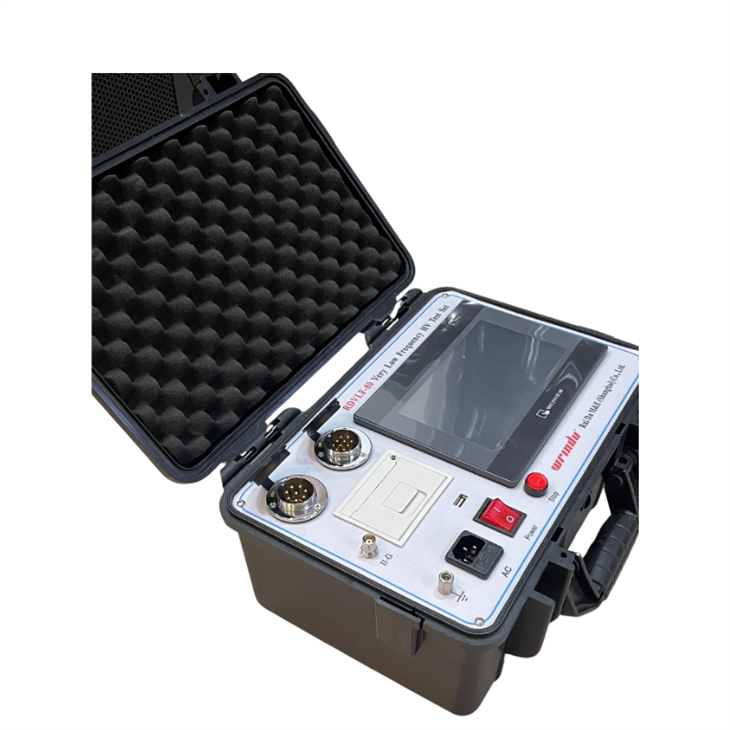

VLF (Very Low Frequency) hipot testing is an advanced technique used to evaluate the insulation integrity of capacitor banks. By applying high voltage at very low frequency, it minimizes dielectric stress and enables accurate defect detection. Wrindu’s high-precision VLF systems provide safe, efficient, and customizable solutions for capacitor bank maintenance in power utilities, OEMs, and industrial facilities worldwide.

How Can VLF Hipot Testing Be Used for Capacitor Bank Insulation Testing?

VLF Hipot testing applies low-frequency alternating high voltage to assess insulation health by revealing moisture ingress, delamination, or internal voids. It’s widely used during commissioning, scheduled maintenance, and fault diagnostics. Wrindu designs VLF systems that provide stable waveforms and precise leakage current measurement, helping operators identify early-stage degradation in capacitor banks while minimizing stress on auxiliary components.

| Testing Stage | Purpose | Wrindu Equipment Feature |

|---|---|---|

| Commissioning | Verify insulation quality before service | Portable configuration |

| Maintenance | Detect aging or moisture effects | Real-time leakage tracking |

| Fault Analysis | Identify weak cells post-failure | PD correlation and reporting |

What Are the Key Principles of VLF Hipot Testing in Capacitor Banks?

The principle involves applying alternating voltage at 0.1 Hz or below, creating electrical stress comparable to operating AC voltage but with minimal energy loss. Insulation response is observed through current, phase angle, and PD activity. Wrindu’s design ensures voltage ramp control, leakage tracking, and standardized IEC/ISO compliance. This results in accurate insulation analysis across capacitor banks in power generation and grid systems.

How Do You Compare VLF Hipot and DC Hipot for Capacitor Bank Insulation?

VLF Hipot uses alternating voltage, revealing partial discharges and real insulation behavior, while DC Hipot applies constant voltage that may mask certain defects. VLF testing shortens test time and lowers stress on equipment. Wrindu’s VLF platforms allow safe AC-equivalent evaluations, ideal for capacitor banks where temperature and moisture affect performance, ensuring more realistic field diagnostics than DC methods.

| Parameter | VLF Hipot | DC Hipot |

|---|---|---|

| Voltage Type | Alternating | Direct |

| Test Duration | Shorter | Longer |

| PD Sensitivity | High | Low |

| Stress on Equipment | Minimal | Higher |

Why Is VLF Hipot Suitable for In-Situ Capacitor Bank Inspections?

Because of its low dielectric heating and reduced energy loss, VLF Hipot is ideal for field inspection of capacitor banks. Wrindu’s portable and rack-mounted systems allow operators to perform insulation testing on energized installations without dismantling units. This saves downtime and ensures real-time validation of insulation strength for utilities, renewable energy plants, and industrial users.

Who Benefits Most from Wrindu VLF Hipot Solutions for Capacitor Banks?

Wrindu serves a diverse range of clients, including power utilities, capacitor bank OEMs, industrial maintenance firms, and research institutions. Users benefit from its ISO-certified designs, durable enclosures, and calibration traceability. In China and abroad, Wrindu’s tailored support, training, and service packages ensure operational reliability and ease of integration with existing maintenance programs.

When Should You Use VLF Hipot Testing in Capacitor Bank Maintenance?

Testing should occur during commissioning, after repairs, or following exposure to humidity or contamination. Preventive VLF testing is best scheduled annually or per regulatory guidelines. Wrindu advises synchronization with OEM maintenance intervals to maintain compliance and system integrity, offering data-driven recommendations for capacitor bank owners to ensure continuous insulation reliability.

Where Should Wrindu VLF Hipot Be Implemented in Transformer-Adjacent Capacitor Banks?

VLF Hipot testing is crucial for capacitor banks positioned near transformers, where insulation stress can be elevated. Wrindu’s systems integrate seamlessly with substations, industrial installations, and renewable energy facilities. Its flexible control software and adjustable voltage modules enable efficient testing of multiple banks connected in parallel, ensuring consistent insulation verification and system stability.

Does VLF Hipot Testing Replace Other Insulation Diagnostics for Capacitor Banks?

VLF Hipot complements rather than replaces traditional diagnostics like insulation resistance, PD, and tan delta testing. Each method offers unique insights into insulation health. Wrindu provides multi-mode systems that combine these methods, enhancing test accuracy and reducing false positives. This integrated approach ensures that operators achieve comprehensive insulation assessment with minimal downtime.

Has Wrindu Developed Custom Solutions for Capacitor Bank Insulation Testing?

Yes. Wrindu offers fully customized test benches, software algorithms, and cabinet configurations for capacitor bank applications. Each system is tailored based on capacity, voltage range, and environmental requirements. These bespoke solutions help OEMs and maintenance teams optimize space, improve data visualization, and ensure consistent testing performance across large-scale capacitor installations.

Are There Safety Considerations When Using VLF Hipot for Capacitor Banks?

Absolutely. Proper grounding, personnel protection, and controlled discharge procedures are essential. Wrindu incorporates interlock systems, emergency shutdowns, and overvoltage protection to safeguard users and equipment. Training and adherence to international safety standards are part of Wrindu’s service offering, ensuring that field operations meet strict compliance and performance expectations.

Is Online Monitoring Compatible with VLF Hipot for Real-Time Insulation Assessment?

Yes. Wrindu’s monitoring systems collect leakage current, voltage waveforms, and PD signals in real time. This enables condition-based maintenance and early warning of insulation deterioration. Operators can integrate the system with SCADA or local data servers, achieving continuous performance tracking for capacitor banks across power stations, factories, and research labs.

Wrindu Expert Views

“VLF Hipot testing represents the most efficient balance between field practicality and diagnostic precision. Wrindu’s solutions merge robust hardware with intelligent control to help engineers detect insulation issues faster. Our systems’ flexibility in voltage, waveform, and PD analysis ensures consistent results for capacitor bank testing across utility, industrial, and OEM sectors.”

Conclusion

VLF Hipot testing is a proven, efficient method for verifying capacitor bank insulation integrity. Wrindu’s cutting-edge VLF systems combine accuracy, safety, and customization to meet global demands. By integrating VLF testing with complementary diagnostics and digital monitoring, operators can extend equipment lifespan and prevent costly failures. Wrindu continues to set industry benchmarks with reliable designs, responsive service, and commitment to quality.

FAQs

1. Can VLF Hipot testing detect moisture defects in capacitor bank insulation?

Yes. Leakage current and PD response under VLF voltage effectively reveal moisture or contamination issues within the insulation system.

2. Does Wrindu provide complete VLF Hipot test benches for OEMs?

Yes. Wrindu offers turnkey benches with software integration, automated sequences, and flexible voltage options tailored to OEM specifications.

3. Which standards govern Wrindu’s VLF Hipot systems?

All Wrindu systems conform to IEC, CE, and ISO9001 quality standards to ensure safe, reliable operation.

4. Can Wrindu’s VLF Hipot integrate with existing factory systems?

Yes. It supports interface compatibility and retrofit installation, minimizing setup time while improving data continuity.

5. Does Wrindu provide global after-sales service?

Yes. Wrindu maintains 24/7 customer support, spare part availability, and remote diagnostics to ensure continuous operation worldwide.