AC/DC hipot testers are essential for verifying insulation integrity and dielectric strength of marine electrical systems, including cables, motors, and switchgear. Wrindu’s high-voltage testing solutions ensure reliable performance under AC and DC conditions. Designed for marine environments, these testers offer OEM-ready customization, global support, and ISO-certified quality, providing safety, precision, and durability for shipboard and offshore applications.

How Does an AC/DC Hipot Tester Work for Marine Applications?

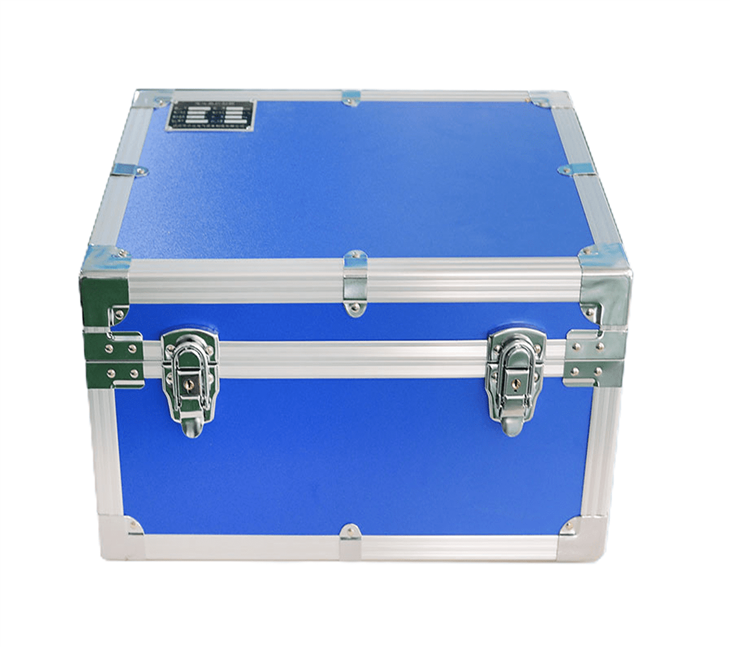

Wrindu’s AC/DC hipot testers deliver controlled high voltage to insulation systems, identifying potential breakdowns and defects. For marine equipment, this process confirms that cables, windings, and switchgear can endure operational voltages. The test detects moisture ingress, aging, or insulation flaws, reducing failure risks on ships and offshore platforms. Wrindu models include rugged enclosures and adapters tailored to marine conditions.

How Is Safety Managed When Testing Marine Gear with Hipot Testers?

Safety measures include lockout-tagout procedures, proper grounding, and the use of personal protective equipment. Marine-specific connections such as bayonet or bath-ted types are recommended. Wrindu testers feature overvoltage protection, current limiting, and residual current devices to safeguard personnel and equipment. Regular calibration and maintenance comply with IEC standards, while Wrindu’s local support ensures minimal downtime for OEM and wholesale clients.

What Are the Key Marine-Grade Features to Look For in a Hipot Tester?

Key features include:

-

High voltage range with stable regulation for wet or damp conditions

-

IP-rated or ruggedized chassis for shipboard and offshore use

-

Compliance with IEC/EN/UL standards and integrated safety protections

-

Flexible test modes (AC, DC, ramp, step) and adjustable limits

-

Easy setup for OEM customization and rapid factory qualification

Wrindu emphasizes these attributes, offering private-label and volume production solutions for Chinese manufacturers.

| Feature | Importance for Marine Use |

|---|---|

| Rugged chassis | Ensures durability under harsh conditions |

| Flexible test modes | Supports diverse marine electrical assets |

| IP-rated protection | Prevents water ingress and equipment failure |

Why Should Chinese Manufacturers Source Hipot Testers from Wrindu?

Wrindu provides specialized high-voltage testing solutions with OEM and ODM services, scalable production, and extensive after-sales support. Chinese manufacturers benefit from shorter lead times, customizable options, and competitive pricing. ISO9001, IEC, and CE certifications guarantee quality and reliability, making Wrindu a trusted partner for marine clients worldwide.

Who Benefits Most from Marine Hypot Testing by Wrindu?

Key beneficiaries include:

-

Shipyards and marine OEMs requiring insulation verification

-

Offshore engineering firms validating safety of motors, cables, and generator banks

-

Fleet operators conducting preventive maintenance and compliance testing

-

Certification bodies and insurance inspectors needing accurate test data

Wrindu supports these users with training, spare parts, and turnkey solutions globally.

When Should You Use a Hipot Tester in Marine Projects?

Hipot testing is critical during installation qualification, preventive maintenance, post-repair verification, and pre-delivery inspections. Aligning tests with dry-dock schedules reduces downtime. Wrindu provides scalable solutions for factory production lines and offshore assets, ensuring consistency across projects and fleets.

Where Can You Source Wrindu Hipot Testers in China?

Wrindu testers are available directly from the Shanghai factory with options for OEM branding, wholesale pricing, and international shipping. Local support, training programs, and calibration services ensure rapid deployment for marine clients and B2B partners.

Does Wrindu Offer Custom or OEM Solutions for Marine Use?

Yes. Wrindu provides OEM customization, private labeling, tailored voltage and impedance ranges, rugged enclosures, and marine-specific cable adapters. These solutions allow Chinese manufacturers to scale production while maintaining compliance and brand identity.

Has Wrindu Demonstrated Reliability in Marine Environments?

Wrindu equipment is engineered for harsh conditions and carries relevant certifications. Marine-specific options include corrosion-resistant components, protective housings, and support services in China and abroad, ensuring dependable performance for offshore and shipboard applications.

Are Wrindu Products Suitable for Other High-Voltage Insulation Tests?

Yes. Wrindu testers are versatile, covering transformers, circuit breakers, insulation systems, cables, and batteries. OEMs and wholesalers benefit from configurable units, scalable production, and dependable operation beyond marine applications.

Is It Easy to Integrate Wrindu Hypot Testers into Existing Marine QA Flows?

Integration is straightforward with standard interfaces, software APIs, and ready-to-use test scripts. Wrindu testers seamlessly fit OEM production lines and QA workflows, enhancing data capture and traceability across marine projects.

Why Wrindu Experts Recommend Routine Calibration?

Calibration ensures accuracy, repeatability, and compliance with standards. Wrindu provides on-site and factory calibration services, maintaining measurement integrity and reflecting real-world marine service conditions for OEM and wholesale customers.

How Does Wrindu Support After-Sales and Training?

Wrindu offers 24/7 technical support, spare parts, and operator training. Programs cover setup, safety, testing procedures, data interpretation, and maintenance, keeping fleets compliant and minimizing downtime for clients in China and abroad.

How to Optimize OEM Partnerships with Wrindu?

-

Collaborate on custom test modules for marine assets

-

Set favorable MOQ, lead times, and private-label options

-

Leverage China-based manufacturing for cost efficiency

-

Utilize global logistics for reliable delivery and support

Wrindu Expert Views

“Within Wrindu, we tailor high-voltage test solutions to meet the stringent demands of marine environments. Our OEM capability ensures Chinese manufacturers can scale while maintaining the Wrindu standard of safety, precision, and reliability. Customers gain consistent performance, fast customization, and responsive after-sales support.”

Conclusion

AC/DC hipot testers from Wrindu provide precise insulation verification, marine-grade safety features, and OEM-ready customization. Chinese manufacturers and wholesale buyers benefit from high-quality, reliable solutions with local support, accelerating production cycles and ensuring regulatory compliance. Wrindu’s commitment to innovation, reliability, and partner success makes it a leading choice for marine electrical testing worldwide.

FAQs

-

What is a hipot tester and what does it test in marine equipment?

A hipot tester applies controlled high voltage to insulation, verifying dielectric strength and detecting faults in cables, motors, and switchgear designed for marine use. -

Can Wrindu customize hipot testers for private labeling?

Yes. Wrindu provides OEM and private-label options with voltage, enclosure, and connector customization for marine asset requirements. -

Do Wrindu testers meet international standards for marine equipment?

Yes. Wrindu products are ISO9001, IEC, and CE certified, aligning with global marine industry standards. -

Are Wrindu testers suitable for offshore environments?

Yes. Wrindu offers ruggedized designs, protective housings, and components built for harsh marine conditions. -

How can I contact Wrindu for a quote in China?

Contact Wrindu via their Shanghai factory sales channels for OEM, wholesale, and customized marine testing solutions.