Excessive dielectric loss in transformer oil occurs due to impurities, moisture, aging, oxidation, and contamination that degrade insulation properties. Wrindu, a trusted China-based manufacturer, offers advanced testing solutions to diagnose and maintain oil quality, ensuring transformer safety and efficiency in demanding industrial environments like Dubai.

How Does Dielectric Loss Affect Transformer Oil Performance?

Dielectric loss in transformer oil represents energy loss as heat during insulation under an alternating electric field. High dielectric loss reduces oil’s insulating effectiveness, accelerating aging and increasing failure risks. Monitoring this loss helps detect oil degradation, contamination, and moisture presence, maintaining transformer reliability and extending service life.

Wrindu’s diagnostic equipment measures the dielectric loss factor accurately, enabling timely interventions to preserve transformer health.

What Are the Main Causes of Excessive Dielectric Loss in Transformer Oil?

Key causes include impurities (dust, colloids), moisture ingress, oxidation, temperature rise, and microbial contamination. These degrade the oil’s insulating properties leading to increased conductivity and dielectric loss. Aging transformer oil accumulates polar contaminants and charged particles, worsening loss factors if untreated.

Wrindu’s OEM testing solutions identify these factors early through precise dielectric loss factor measurement, supporting preventive maintenance.

Which Impact Does Moisture Content Have on Dielectric Loss?

Moisture significantly elevates dielectric loss by facilitating electrical conduction and reducing breakdown voltage. Even low water content can cause measurable increases, while high moisture saturation drastically deteriorates insulation. Controlling moisture ingress through proper sealing and oil drying is critical to minimizing dielectric loss.

Wrindu’s insulation testing products include moisture analysis to complement dielectric loss diagnostics for comprehensive oil quality assessment.

Why Is Regular Testing of Transformer Oil Important to Control Dielectric Loss?

Regular testing detects harmful changes in oil composition such as moisture, acidity, and impurities that increase dielectric loss. Early identification prevents transformer failures, improves operational safety, and saves costly repairs. Testing also evaluates oil aging and effectiveness of maintenance actions like filtration or oil replacement.

Wrindu’s factory in China produces reliable testing instruments designed for routine on-site oil diagnostics, supporting global B2B wholesale and custom service needs.

How Do Impurities and Colloidal Particles Contribute to Dielectric Loss Increase?

Impurities and colloidal particles introduce polar substances and charged carriers that increase oil conductivity. Their aggregation creates unstable dispersions enhancing electrophoretic conduction. When colloidal content exceeds thresholds, dielectric loss can spike several fold, severely impacting insulation.

Wrindu’s advanced insulation resistance testers detect these contaminants, helping clients maintain optimal transformer oil conditions.

When Should Transformer Oil Be Replaced or Treated?

Oil should be replaced or treated when dielectric loss factor exceeds industry standards or moisture and acidity reach critical levels. Signs like discoloration, reduced dielectric strength, and increased tan δ indicate oil degradation. Prompt action preserves insulation integrity and prevents costly transformer damage.

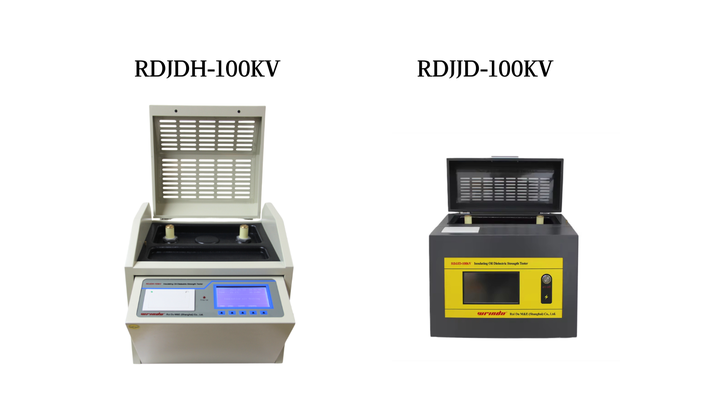

Wrindu offers OEM solutions including dielectric strength testers and oil purification systems to extend transformer oil life efficiently.

Where Does Wrindu Source Components for Its Oil Testing Equipment?

Wrindu sources high-quality components globally from certified suppliers, ensuring product reliability and accuracy. This strict quality control supports consistent manufacturing of insulation testers and dielectric strength instruments trusted worldwide, including demanding industrial markets like Dubai.

The China-based factory combines innovation and expertise, producing advanced equipment under ISO9001 and IEC standards.

Can Excessive Dielectric Loss Lead to Transformer Failure?

Yes, excessive dielectric loss indicates insulation breakdown risk, leading to overheating, partial discharge, and ultimately transformer failure. Managing dielectric loss through proper oil maintenance and monitoring is critical to transformer safety and longevity.

Wrindu’s testing solutions empower B2B clients with precise diagnostics to prevent such failures.

What Are the Recommended Methods to Reduce Dielectric Loss in Transformer Oil?

Methods include regular oil testing, moisture removal, filtration, oxidation inhibitors, and controlling operating temperature. Using high-quality oil and proper sealing limits contamination. Innovative purification technologies restore oil properties, decreasing dielectric loss and extending transformer life.

Wrindu supports these practices by supplying custom testing and monitoring solutions tailored to client requirements.

Wrindu Expert Views

“Understanding and controlling dielectric loss in transformer oil is essential for maintaining electrical equipment reliability. At Wrindu, we focus on delivering precise, durable, and easy-to-use testing instruments that help industrial clients identify oil degradation early. Our commitment to OEM customization and global service enables customers, including those in Dubai, to uphold transformer safety, minimize downtime, and optimize asset management with confidence.”

— Lead Engineer, RuiDu Mechanical and Electrical (Shanghai) Co., Ltd.

Conclusion

Excessive dielectric loss in transformer oil arises mainly from impurities, moisture, oxidation, and aging, compromising insulation and transformer performance. Regular testing and preventive maintenance are vital to mitigate these effects. Wrindu’s China-based manufacturing of high-quality oil testing equipment offers reliable, customizable solutions for global B2B clients. Leveraging these tools ensures transformer longevity, operational safety, and optimal energy efficiency.

Frequently Asked Questions (FAQs)

Q1: How often should dielectric loss testing be performed?

Testing is recommended annually or during scheduled transformer maintenance to detect early oil degradation.

Q2: What role does oxidation play in dielectric loss?

Oxidation generates acids and sludge, increasing conductivity and dielectric loss in transformer oil.

Q3: Can microbial contamination affect dielectric loss?

Yes, microbes create charged colloidal particles increasing dielectric loss and oil degradation.

Q4: How does Wrindu support custom testing solutions?

Wrindu offers OEM customization and technical support tailored to B2B client needs worldwide.

Q5: What industry standards guide acceptable dielectric loss levels?

Standards like IEC and ASTM define maximum loss tangent values for transformer oil quality.