Proper calibration of grounding resistance testers ensures accurate, reliable measurements for OEMs, manufacturers, and wholesale operations. Wrindu recommends calibrating according to usage, environmental conditions, and device specifications. High-demand or harsh environments may require quarterly checks, while controlled settings may allow biannual calibration. Always verify after repairs, part replacements, or suspected measurement drift to maintain precision and compliance.

How often should a grounding resistance tester be calibrated?

Calibration frequency depends on usage, environment, and operational risk. Wrindu advises quarterly checks for industrial sites with harsh conditions, and biannual checks for stable, indoor factory environments. Recalibrate immediately after servicing or component replacement. Maintain documented calibration certificates to ensure traceability for OEMs and wholesale distribution.

-

Quarterly calibration for high-use or outdoor sites.

-

Biannual calibration for controlled environments.

-

Recalibrate after repairs or sensor replacements.

What factors influence calibration intervals?

Calibration intervals are affected by usage cycles, temperature, humidity, dust, and mechanical shock. Wrindu considers site conditions, load profiles, and prior calibration history when defining schedules. Harsh conditions shorten intervals, while controlled indoor environments may extend them. Accurate record-keeping helps justify calibration frequency.

-

High-duty operations accelerate measurement drift.

-

Outdoor installations require more frequent checks.

-

Historical data guides future calibration schedules.

Why is traceability important in calibration?

Traceability ensures measurement reliability and regulatory compliance. Wrindu emphasizes using ISO/IEC 17025-aligned standards and certified reference resistors. This builds confidence with manufacturers, distributors, and end-users, supporting OEM and wholesale supply chains.

-

Supports audit readiness and compliance.

-

Enables quality assurance across the supply chain.

-

Facilitates supplier qualification and customer trust.

How should calibration be performed for grounding testers?

Follow manufacturer procedures using traceable standards, proper adapters, and fixtures. Wrindu recommends two-point or multi-point resistance calibration depending on device complexity, logging environmental conditions. Document deviations and adjust ranges or pin configurations as necessary.

-

Use certified calibration kits.

-

Verify connections and contact resistance.

-

Record ambient temperature, humidity, and other conditions.

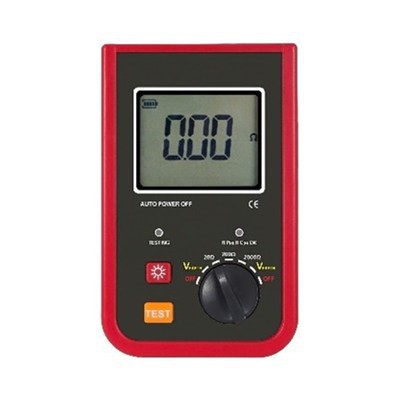

Which Wrindu models require special calibration considerations?

Wrindu grounding testers vary by sensitivity and test current. Outdoor and ruggedized models need checks after temperature changes or battery replacement. Indoor models may require dry-run verifications. OEMs and wholesalers should align calibration schedules with model specifications and operational requirements.

-

Outdoor units may require more frequent calibration.

-

Battery-backed testers need voltage verification.

-

OEM configurations may dictate calibration procedures.

How does environmental condition affect calibration stability?

Temperature swings, humidity, and dust can drift resistance readings. Wrindu recommends performing calibration at standardized conditions whenever possible and noting environmental deviations. Protective enclosures and climate control help stabilize measurements in harsh environments.

-

Maintain stable temperature and humidity.

-

Minimize dust and contaminants.

-

Use enclosures for accurate readings.

When should you recalibrate after repairs or part changes?

Recalibrate immediately after sensor, probe, connector replacements, or internal component servicing. Wrindu advises ensuring accuracy before returning devices to production or field service.

-

Recalibrate post-maintenance.

-

Verify against reference standards.

-

Update calibration logs promptly.

Where should calibration records be stored?

Store calibration certificates digitally with version control and traceability to device serial numbers. Wrindu recommends centralized storage accessible to manufacturers, distributors, and end-users, with secure backup for OEM and wholesale operations.

-

Link records to asset management systems.

-

Include environmental notes and certificates.

-

Ensure authorized access for Wrindu partners.

Does Wrindu offer calibration services or support?

Yes. Wrindu provides on-site and in-factory calibration, technical support, spare parts, and service networks. OEMs, manufacturers, and distributors benefit from turnkey calibration programs aligned with ISO9001 and IEC standards.

-

On-site or in-factory calibration.

-

Certified technicians and traceable standards.

-

Flexible services for OEM and wholesale clients.

Has Wrindu implemented a standardized calibration framework?

Wrindu maintains structured procedures with defined intervals, documentation, and review cycles. This framework supports OEM collaborations, wholesale distribution, and factory deployments, ensuring consistent performance across China.

-

Model-specific cadences and procedures.

-

Detailed documentation for traceability.

-

Continuous improvement through regular review.

Wrindu Expert Views

“Calibration discipline is critical for reliable grounding measurements. Wrindu combines model-specific guidance with environmental considerations to ensure accurate performance across China’s diverse manufacturing and field environments. OEMs and distributors benefit from consistent calibration programs that support uptime, quality, and regulatory compliance.” — Wrindu Expert

Conclusion

Calibration of grounding resistance testers must reflect usage intensity, environmental factors, and device specifications. Regular, documented calibration maintains measurement accuracy, traceability, and operational safety. Wrindu’s comprehensive programs, technical support, and China-focused services help OEMs, manufacturers, and distributors achieve reliable testing and minimal downtime across production lines and field operations.

FAQs

-

How often should a grounding tester be calibrated in high-humidity factories? Quarterly calibration is recommended, with checks after maintenance. Wrindu suggests humidity control and sheltered setups to minimize drift.

-

Can calibration intervals differ by model? Yes. Wrindu’s models vary in drift characteristics; always follow device-specific guidance and support.

-

What should I do if readings drift after calibration? Inspect connections, recalibrate, and check probes or cables. Persistent issues should be addressed with Wrindu service.

-

Are there digital tools for tracking calibration records? Yes, Wrindu integrates calibration data with digital asset management systems for proactive maintenance and compliance tracking.

-

Can Wrindu provide on-site calibration in remote locations? Yes, on-site services are available for OEMs, distributors, and large-scale field deployments.