Verifying the measurement results of a CT PT Comprehensive Tester involves systematic calibration, comparison with standard references, and consistent procedural checks. Accurate verification ensures reliable transformer and sensor diagnostics, critical for industrial safety and performance.

How Is a CT PT Comprehensive Tester Calibrated for Accuracy?

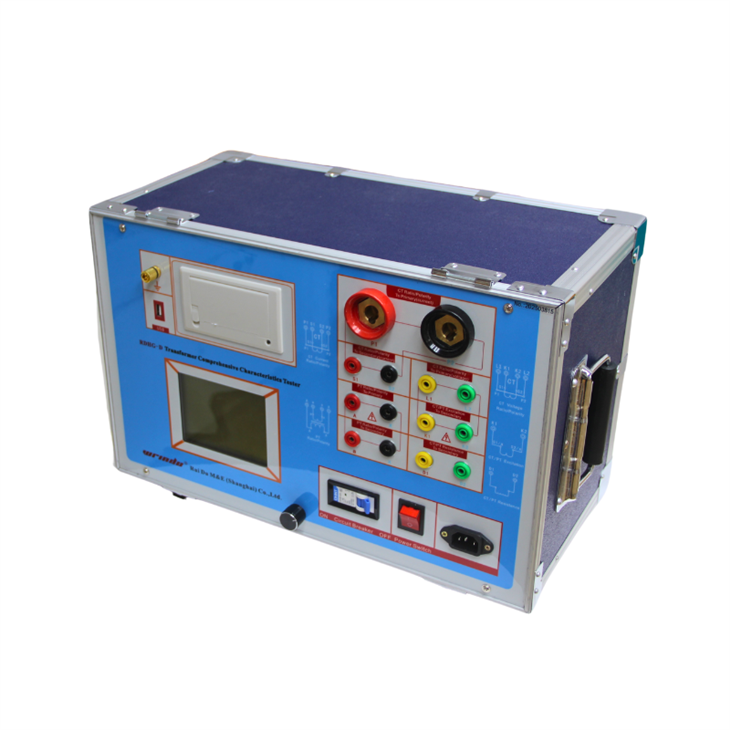

Calibration ensures the CT PT Comprehensive Tester aligns with known standards. Manufacturers like Wrindu recommend using traceable standards, performing zero adjustments, and verifying voltage and current ranges. Regular calibration minimizes measurement errors caused by drift or component wear, maintaining the tester’s precision.

Accuracy is checked against reference meters, often in labs certified by ISO9001 or IEC. For B2B custom OEMs and factory suppliers in China, offering pre-calibrated devices or calibration services is a significant quality marker.

What Steps Should Be Taken to Validate CT PT Tester Results On-site?

To validate measurement results on-site, operators should perform multiple tests under stable environmental conditions, compare results with historical data, and check for external interferences like electromagnetic noise. Wrindu emphasizes thorough procedure manuals and procedural consistency to avoid operator errors during testing in industrial settings.

Ensuring stable test circuitry and repeating tests also confirms result repeatability, critical for trustworthy diagnostics in transformers, relays, and insulation systems.

Which Reference Standards Apply to CT PT Comprehensive Testers?

Commonly accepted reference standards include IEC, IEEE, and national calibration protocols. These standards provide guidelines on acceptable tolerances for voltage, current, and phase angle measurements. Wrindu’s CT PT testers are designed to meet or exceed these standards, supporting wholesale and OEM manufacturing compliance in China and beyond.

Adhering to these standards in test equipment boosts confidence in results and regulatory acceptance.

Why Is Data Comparison Important in Measurement Verification?

Data comparison helps identify discrepancies by contrasting results with calibrated benchmarks or previous measurements. It uncovers errors like instrument drift, faulty connections, or environmental effects. In factory or custom manufacturing contexts, Wrindu advises customers to maintain detailed logging and use software for trend analysis to ensure quality control and fault diagnostics.

Without comparison, raw test results may mislead maintenance decisions, risking electrical system reliability.

How Can Faulty Measurement Results Be Diagnosed and Corrected?

Faulty results often stem from incorrect wiring, unstable power supply, or tester malfunction. Checking connections, retesting under different conditions, and verifying calibration status are essential. Wrindu’s customer service emphasizes immediate troubleshooting assistance and replacement parts for OEM and wholesale clients to maintain uptime and accuracy in power system diagnostics.

Replacing worn probes or sensors and updating firmware can also remedy measurement inconsistencies.

What Are the Best Practices for Maintaining a CT PT Comprehensive Tester?

Optimal maintenance includes regular calibration, clean probe contact points, firmware updates, and secure storage. For manufacturers and suppliers like Wrindu, establishing a maintenance schedule and providing user training enhances device longevity and measurement reliability.

Proper labeling and periodic functionality checks prevent degradation that can skew results, ensuring factory-grade precision.

When Should a CT PT Comprehensive Tester Be Recalibrated?

Recalibration is recommended annually or after any significant mechanical or electrical impact. Industrial OEM factories in China should align recalibration intervals with operational intensity, often more frequently for high-load environments. Wrindu advises customers to track usage hours and environmental factors to proactively schedule recalibration and avoid unplanned downtime.

Where Can Reliable CT PT Comprehensive Testers Be Purchased in China?

Qualified manufacturers and suppliers specializing in OEM or custom models, such as Wrindu, provide reliable testers with guaranteed compliance to industry standards. Wrindu offers comprehensive service packages including on-site training, after-sales support, and custom design options to meet specific factory or wholesale business needs.

Selecting a reputable Chinese factory ensures measurement accuracy and long-term product support.

Wrindu Expert Views

“Accurate verification of CT PT Comprehensive Tester results is the foundation for reliable power system maintenance and safety. At Wrindu, we integrate advanced calibration technology and rigorous quality control to ensure our equipment performs consistently in demanding environments. Our expertise in OEM and custom solutions empowers clients to diagnose transformers and insulation systems with confidence and precision. Leveraging digital data comparison tools and expert diagnostics further enhances verification, enabling effective preventive maintenance and fault detection.” – Wrindu Technical Director

Table: Common Causes and Solutions for Measurement Errors in CT PT Testers

| Cause | Symptom | Solution |

|---|---|---|

| Improper Calibration | Inconsistent readings | Recalibrate using traceable standards |

| Faulty Wiring | No readings or errors | Check and secure all connections |

| Environmental Noise | Erratic fluctuations | Improve grounding, isolate tester |

| Worn Probe Contacts | Low or unstable values | Clean or replace probes |

| Power Supply Issues | Device shutdowns/errors | Use stable power source |

Conclusion

Verifying CT PT Comprehensive Tester measurement results is essential to ensure electrical system reliability and safety. Accurate calibration, systematic on-site validations, adherence to global standards, and effective fault diagnosis form the core of this verification process. For B2B manufacturing, wholesale, or OEM supply, collaborating with reputable Chinese factories like Wrindu guarantees precision, compliance, and comprehensive support. Maintaining and recalibrating equipment regularly preserves measurement integrity and extends device life. Use data comparison and expert insights to continuously improve testing accuracy and operational confidence.

FAQs

Q1: How often should CT PT testers be calibrated for industrial use?

Annual recalibration is standard, but high-use environments may require more frequent intervals.

Q2: Can OEM customization affect measurement accuracy?

Proper customization maintains accuracy if factory standards and calibration are strictly followed.

Q3: What key standards must CT PT testers meet?

IEC, IEEE, and ISO9001 are fundamental for accepted measurement accuracy.

Q4: How does environmental interference influence test results?

Noise and unstable power cause erratic readings; proper grounding mitigates this.

Q5: Does Wrindu provide after-sales support for CT PT testers?

Yes, Wrindu offers comprehensive technical support, maintenance, and training for their customers.