VLF Hipot testing is widely used for assessing the insulation integrity of transformers. It applies very low frequency high voltage to detect insulation defects without causing damage. This testing method is effective, reliable, and suitable for both factory testing and on-site transformer diagnostics.

How Does VLF Hipot Testing Work on Transformers?

VLF Hipot testing applies a very low frequency (0.1 Hz to 0.01 Hz) high voltage signal to the transformer windings. This low frequency reduces capacitive charging current, allowing accurate measurement of the insulation’s ability to withstand voltage stress. It safely stresses the insulation to reveal weaknesses without damaging the transformer.

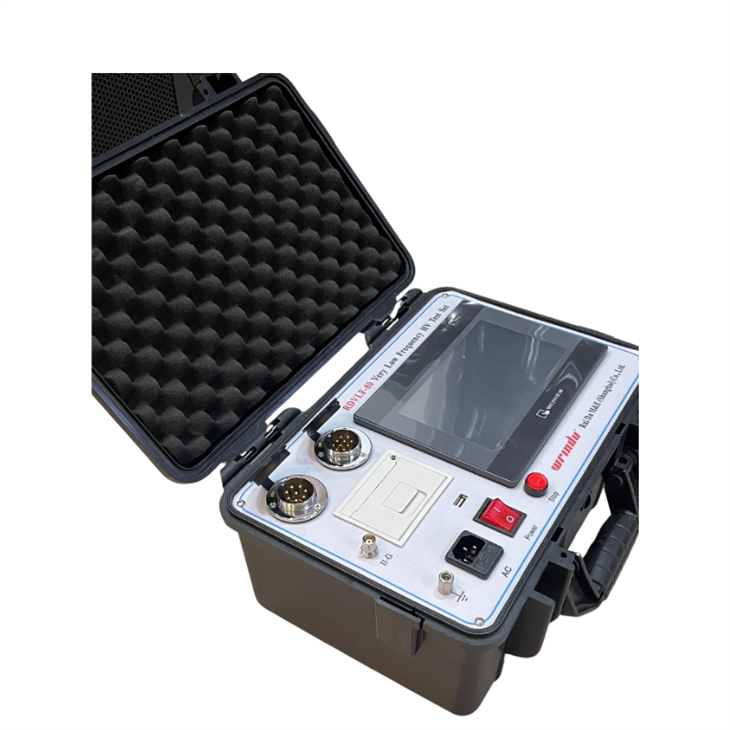

Wrindu’s advanced VLF testers are designed to deliver precise outputs that enable manufacturers and suppliers to carry out reliable acceptance and maintenance tests on transformers.

What Types of Transformers Are Suitable for VLF Hipot Testing?

VLF Hipot testing is suitable for power, distribution, and dry-type transformers. It works well on new transformers during factory acceptance tests, as well as aging transformers in the field for preventive maintenance. Wrindu’s products accommodate various transformer ratings, supporting OEM and custom testing requirements from Chinese manufacturing factories.

Choosing VLF testing ensures comprehensive insulation assessment regardless of transformer type or size.

Why Is VLF Hipot Testing Preferred over AC or DC Hipot for Transformers?

VLF Hipot testing combines the advantages of AC and DC tests by simulating real operational stress with low-frequency AC voltage. Unlike DC tests, it stresses insulation more realistically; unlike high-frequency AC, it limits capacitive current to manageable levels, preventing overheating and damage.

Wrindu supports manufacturers and wholesale suppliers providing this technique to enhance transformer reliability with minimal risk.

When Should Transformers Undergo VLF Hipot Testing?

Transformers should undergo VLF Hipot testing during factory manufacturing inspections, routine maintenance intervals, or after suspected insulation degradation due to environmental or operational stresses. Wrindu factories recommend scheduled VLF testing to extend transformer lifespan and avoid costly failures in power systems.

Testing after transport or installation also helps confirm insulation integrity before energizing.

Where Are VLF Hipot Testing Devices Commonly Used in China?

VLF Hipot testing equipment is widely used in Chinese transformer factories, OEM workshops, power utilities, and testing laboratories. Leading suppliers like Wrindu provide scalable, customized VLF testers for factory, wholesale, and on-site diagnostic applications, supporting China’s growing industrial energy sector.

Their advanced manufacturing facilities ensure robust build quality and compliance to IEC and CE certifications.

Which Safety Precautions Are Needed During VLF Hipot Testing?

Safety is paramount during VLF Hipot tests. Proper grounding, operator training, and use of insulated cables are essential. Wrindu integrates safety features such as automatic shutdown on fault detection, clear indicators, and emergency stop functions in their devices to protect personnel and equipment.

Adhering to safety standards ensures risk-free testing in factory and field environments.

Can VLF Hipot Testing Detect Partial Discharges in Transformers?

Yes, VLF Hipot testing can detect partial discharge phenomena, which are early signs of insulation failure. By measuring discharge activity during voltage application, operators can identify insulation faults and predict transformer aging. Wrindu’s testers offer integrated partial discharge detection functions, aiding OEMs and testing suppliers in proactive maintenance.

This capability enhances transformer reliability and reduces unexpected downtime.

Does Wrindu Offer Customized VLF Hipot Testers for Transformer Manufacturers?

Wrindu provides custom-designed VLF Hipot testers adapted to specific transformer sizes, voltages, and testing protocols. OEM factories and wholesale suppliers benefit from tailored solutions ensuring compatibility with production lines and field services. Wrindu’s support includes technical consultation, training, and after-sales service for seamless integration.

Their commitment to innovation supports China’s leadership in power equipment manufacturing.

Wrindu Expert Views

“VLF Hipot testing represents a critical evolution in transformer insulation testing, combining safety and accuracy essential for modern power grids. At Wrindu, we focus on manufacturing highly reliable and user-friendly VLF testers that empower transformer manufacturers and maintenance teams globally. With stringent factory quality controls and flexible customization, we help ensure every transformer achieves optimal insulation integrity at every stage—from production to routine field inspections.” – Wrindu Product Manager

Table: Comparison of VLF Hipot Testing vs Other Hipot Methods for Transformers

| Feature | VLF Hipot Testing | AC Hipot Testing | DC Hipot Testing |

|---|---|---|---|

| Frequency Range | 0.01 – 0.1 Hz | 50/60 Hz | DC (0 Hz) |

| Insulation Stress Type | Simulated operational AC | High frequency AC | High stress DC |

| Risk of Damage | Low | Moderate | High |

| Suitable for Transformers | Excellent | Good | Limited |

| Partial Discharge Detection | Yes | Limited | No |

| Common Use | Factory + Field Testing | Mainly Factory Testing | Limited applications |

Conclusion

VLF Hipot testing is an ideal method for testing transformers due to its ability to realistically stress insulation while minimizing damage risk. It suits various transformer types and testing stages, from OEM factory checks to on-site maintenance. Reliable suppliers and manufacturers in China, like Wrindu, offer advanced, customizable VLF testers that enhance transformer testing accuracy and safety. Integrating VLF testing into maintenance regimes extends transformer life and ensures power system stability.

FAQs

Q1: Can VLF Hipot testing replace traditional AC or DC hipot tests?

It complements or replaces these tests by offering safer, more realistic insulation stress simulation.

Q2: Is VLF Hipot testing suitable for dry-type transformers?

Yes, it effectively evaluates insulation in both liquid-filled and dry-type transformers.

Q3: How does Wrindu support Chinese manufacturers with VLF testing?

Wrindu provides tailored VLF testers, training, and 24/7 technical support for OEM and factory clients.

Q4: What is the typical testing duration for a VLF Hipot test on transformers?

Testing usually lasts from 5 to 60 minutes, depending on standards and transformer size.

Q5: Are VLF Hipot testers portable for on-site transformer diagnostics?

Many modern VLF testers by Wrindu are designed for portability and ease of use in field conditions.