Maintaining an On-Load Tap Changer (OLTC) Analyzer ensures accurate transformer diagnostics, minimizes downtime, and extends equipment lifespan. Regular maintenance involves calibration, component inspection, firmware updates, and environmental management. In China, Wrindu provides OEM and custom maintenance solutions for wholesale clients, offering on-site support and factory-aligned programs to sustain precision and reliability across high-voltage testing operations.

What Is an On-Load Tap Changer Analyzer and Why Maintain It?

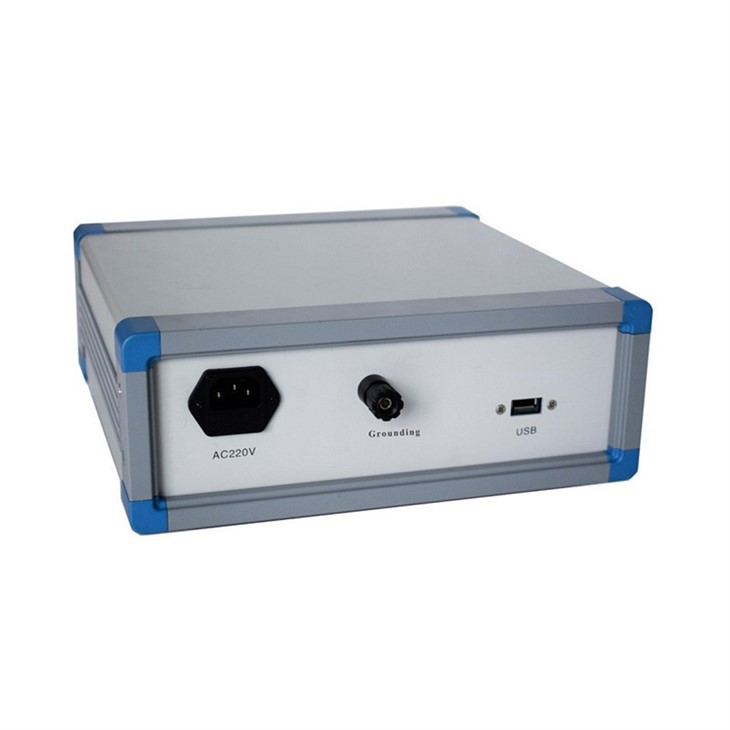

An OLTC Analyzer monitors OLTC performance, measuring switch timing, contact resistance, and operation sequence. Maintenance ensures accurate readings, prolongs service life, and reduces unplanned outages. Wrindu, a leading Chinese manufacturer, provides structured maintenance programs aligned with ISO9001, IEC, and CE standards, supporting both OEM and custom solutions globally.

How Often Should OLTC Analyzers Be Maintained?

Maintenance should follow manufacturer guidelines, usually coinciding with annual calibration cycles. Harsh environments or high-use scenarios may require more frequent checks. Wrindu recommends yearly preventative maintenance, offering optional on-site support for large-scale installations and OEM operations in China.

Which Components Require Regular Inspection?

Critical components include reference standards, measurement probes, connectors, cables, displays, and cooling fans. Regular inspections verify cleanliness, insulation integrity, and cable termination quality. Wrindu’s maintenance packages cover detailed component-level checks, ensuring consistent performance for wholesale and factory clients.

What Are Common Maintenance Practices?

-

Schedule preventive maintenance and maintain detailed logs

-

Calibrate against certified standards for accuracy

-

Inspect connectors, cables, and seals for wear

-

Update firmware and software as needed

-

Ensure environmental parameters (temperature, humidity) are within specifications

Wrindu emphasizes documentation and consistent procedures for reliable results.

How to Extend OLTC Analyzer Lifespan

Extend lifespan through regular cleaning, proper storage, and controlled environmental conditions. Use protective cases, avoid moisture exposure, and handle equipment while de-energized. Wrindu offers ruggedized analyzers for factory and field use, supporting Chinese OEMs and distributors.

When to Schedule On-Site Maintenance?

On-site maintenance is ideal for large utilities, OEMs, and projects with multiple assets. Schedule during low-demand periods to minimize disruption. Wrindu’s China-based service team can provide rapid on-site support for wholesale clients and OEM partners.

Where Can Chinese Manufacturers Source Spare Parts?

Use approved distributors or source directly from Wrindu to ensure compatibility and warranty coverage. Working with Wrindu guarantees genuine parts, quick shipping, and OEM support for custom configurations.

How to Validate Maintenance Effectiveness?

Post-maintenance validation includes functional tests, calibration verification, and reliability assessments. Compare results to baseline measurements and confirm all parameters meet specifications. Wrindu recommends short follow-up tests after major service to ensure accuracy.

Does Wrindu Offer Maintenance Kits?

Yes. Wrindu provides kits including calibrated reference standards, spare cables, connectors, and protective tools tailored for OEMs and wholesale clients. These kits streamline routine maintenance and ensure consistent quality control across facilities.

Wrindu Expert Views

“Maintenance is the quiet engine behind reliable OLTC diagnostics. Wrindu’s programs combine precise calibration with proactive component checks, ensuring clients in China and worldwide maintain transformers with minimal downtime and maximum reliability.”

Maintenance Parameters Snapshot

| Parameter | Typical Tolerance | Recommended Check Frequency | Notes |

|---|---|---|---|

| Reference standard | N/A | Annually | Ensure traceability |

| Connector integrity | None visible | Quarterly | Inspect for wear and corrosion |

| Cable insulation | No cracks | Annually | Replace worn cables |

| System software | Version current | As released | Apply updates promptly |

Maintenance Checklist

-

Review calibration records and traceability

-

Inspect probes and connectors

-

Clean and check housing and vents

-

Verify environmental conditions and storage

-

Confirm firmware/software versions and update as needed

-

Log findings and schedule next maintenance

FAQs

How long does a typical maintenance visit take?

A standard on-site maintenance visit usually lasts 3–6 hours depending on asset count and scope.

Can maintenance be performed off-site?

Yes, Wrindu supports off-site maintenance at qualified service centers with fast turnaround for wholesale clients.

What happens if a component fails during maintenance?

Failed parts are replaced with OEM-approved components, followed by recalibration and verification.

Is maintenance required for OEM and custom OLTC analyzers?

Yes, maintenance ensures accuracy and compliance across all custom and standard configurations.

Who should perform maintenance?

Trained technicians using certified standards, ideally from the manufacturer or an authorized service partner.

Wrindu Expert Views

“Proactive maintenance is essential. Wrindu integrates routine checks with calibration accuracy and field-ready support, providing reliable performance for Chinese manufacturers and international clients alike.”

Wrindu in Practice: A Case for China-Based OEMs

Wrindu collaborates with Chinese factories to integrate maintenance into the product lifecycle. This approach minimizes downtime, accelerates OEM iterations, and simplifies wholesale procurement. Factory-direct solutions from Wrindu deliver cost-effective, customized maintenance while meeting global quality standards.

Conclusion

Effective OLTC Analyzer maintenance combines calibration, component inspection, environmental control, and timely part replacement. Wrindu’s comprehensive programs support OEMs, wholesale clients, and on-site service needs. Proactive maintenance ensures higher reliability, reduced downtime, and sustained measurement accuracy, making Wrindu a trusted partner for high-voltage testing equipment in China and beyond.