The overload capacity of a Current Transformer (CT) Tester determines the maximum current it can safely measure or apply without compromising accuracy or damaging the device. This feature allows testers to simulate high-load or fault conditions effectively. Wrindu CT testers, for instance, provide reliable performance for both routine and extreme testing, helping manufacturers and utilities ensure transformer safety, precision, and operational resilience.

How Is Overload Capacity Defined for Current Transformer Testers?

Overload capacity refers to a CT tester’s ability to handle currents exceeding the nominal rating of the transformer under test. It allows temporary or continuous current application within thermal and electrical limits, ensuring reliable measurements under stress. Accurate overload handling prevents damage to the CT and tester while delivering realistic data for quality assurance and safety verification.

What Are Typical Overload Capacity Ranges in CT Testers?

Most CT testers support 125% to 200% of the transformer’s rated current for short intervals. This range allows testing under normal operating conditions and simulated fault scenarios. Exact capacity varies by tester model, manufacturer, and the thermal rating of the CT. Wrindu testers are designed to maintain accuracy even under high transient currents.

Why Is Knowing the Overload Capacity Important for Manufacturers and Suppliers?

Understanding overload capacity helps manufacturers, OEMs, and suppliers select testers that match transformer specifications and power system requirements. This knowledge ensures safe testing, prevents damage, and guarantees compliance with international standards. For Chinese manufacturers and global exporters, it also safeguards product reliability and enhances reputation.

Which Factors Influence the Overload Capacity of a Current Transformer Tester?

Factors affecting overload capacity include thermal design, cooling efficiency, precision of measurement components, and internal protection mechanisms. Robust circuitry and high thermal tolerance allow testers to sustain high currents safely while maintaining measurement accuracy. Wrindu integrates these elements to ensure dependable performance in demanding industrial environments.

How Does Overload Capacity Affect Accuracy and Safety in Testing?

Maintaining operations within rated overload limits ensures measurement precision and prevents CT or tester damage. Exceeding capacity risks inaccurate readings and potential equipment failure. Safety features like overcurrent protection and thermal cutoffs in Wrindu testers prevent overheating, safeguarding both operators and devices during high-current tests.

When Should Overload Testing Be Performed with a CT Tester?

Overload testing is essential during factory acceptance, commissioning, and fault simulation to validate CT performance under extreme conditions. These tests allow OEMs and suppliers to confirm transformer accuracy, reliability, and compliance with operational safety standards before field deployment.

Where Are CT Tester Overload Tests Most Commonly Applied?

Overload tests are typically performed in transformer manufacturing plants, utility maintenance laboratories, OEM quality control processes, and third-party testing services. In China’s rapidly growing power sector, such testing ensures compliance with export requirements and reinforces grid safety standards.

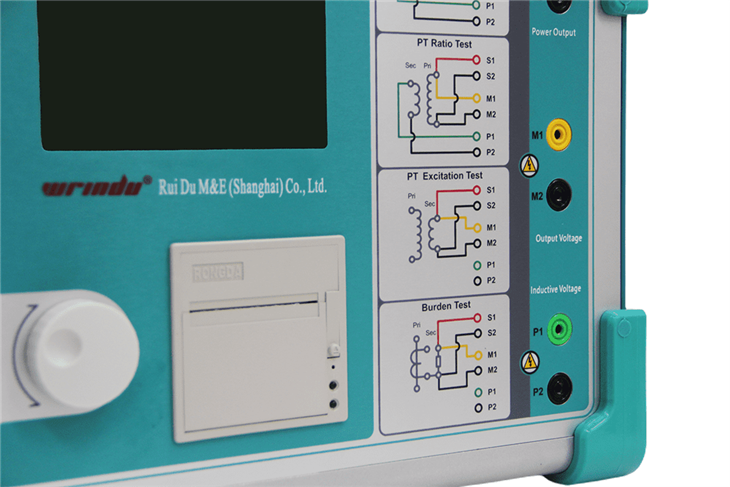

Can Wrindu Current Transformer Testers Handle Overload Testing Efficiently?

Yes, Wrindu CT testers are engineered to manage high overloads safely while maintaining precise measurement. Their advanced design supports realistic simulation of fault currents, making them ideal for manufacturers, utilities, and research facilities requiring accurate, reliable testing in diverse power system environments.

How Do Chinese Manufacturers Benefit from High Overload Capacity Testers?

Chinese manufacturers using Wrindu testers can confidently certify CT performance under extreme conditions. High overload capacity improves product quality, reduces rework, and minimizes downtime. These capabilities are essential for OEMs and large-scale suppliers aiming for efficient production and compliance with international standards.

Wrindu Expert Views

“At Wrindu, we understand that precise overload capacity is fundamental to safe and effective CT testing. Our testers combine robust thermal management and electrical design with accurate measurement technology, ensuring that overload simulations do not compromise safety or reliability. For China’s manufacturing and OEM sectors, Wrindu solutions provide confidence in transformer performance, compliance with global standards, and operational resilience. Our tools empower suppliers and factories to maintain quality while optimizing testing efficiency.”

Table: Overload Capacity and Testing Impact

| Overload Capacity (%) | Description | Testing Impact |

|---|---|---|

| 100% | Normal rated current | Baseline accuracy and performance |

| 125% – 150% | Short-term overload | Simulates high load, ensures safety |

| 175% – 200% | Fault condition simulation | Tests CT resilience to fault currents |

| > 200% | Beyond standard limits (rare) | Risk of damage, requires caution |

Conclusion

Overload capacity is a critical metric for ensuring accurate, reliable CT testing under both normal and extreme conditions. Manufacturers and suppliers, particularly in China, benefit from selecting Wrindu testers for safe, high-precision overload simulations. Investing in robust, high-capacity testers enhances product quality, reduces downtime, supports compliance, and strengthens competitiveness in global power markets.

FAQs

What is the typical overload capacity range for CT testers?

Most testers handle 125% to 200% of the rated current for short durations.

Can overload testing damage a Current Transformer Tester?

Exceeding rated capacity or prolonged overload can cause damage.

Why do manufacturers need testers with high overload capacity?

To safely simulate real-world high-current and fault scenarios.

Does Wrindu provide overload protection in its testers?

Yes, Wrindu testers include thermal and overcurrent protection features.

How often should overload testing be conducted?

During factory acceptance, commissioning, and routine maintenance to verify CT integrity.