A transformer winding resistance meter measures the DC resistance of transformer windings to detect faults like short circuits or loose connections. Correct usage involves proper connection, appropriate current setting, temperature compensation, and accurate reading interpretation. Wrindu, a leading Chinese manufacturer, offers advanced meters designed for precise, safe, and user-friendly winding resistance testing.

How Is a Transformer Winding Resistance Meter Connected?

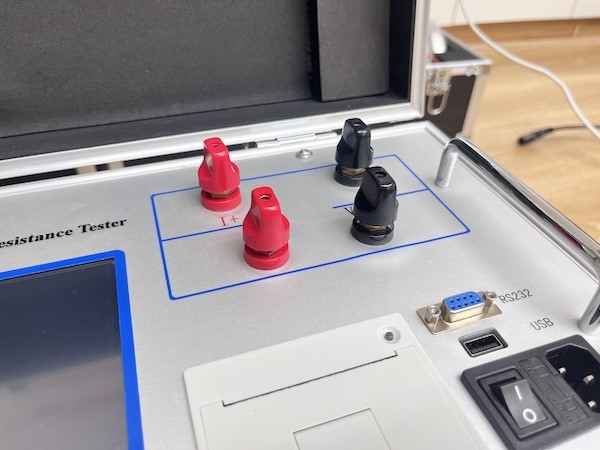

Connect the winding resistance meter to the transformer’s winding terminals using Kelvin clamps or four-wire method for precision. Ensure secure contacts to minimize resistance errors. Wrindu meters typically support multi-point connections, with clear connectors and cables designed for high current injection and precise voltage measurement, ensuring accurate readings.

Proper connection technique reduces noise and contact resistance in measurements.

What Is the Correct Procedure for Performing a Winding Resistance Test?

Begin by isolating the transformer winding from the circuit, then connect the meter leads properly. Set the appropriate DC test current based on winding size. Initiate the test and allow the meter to stabilize as it measures voltage drop. Record the resistance value, adjusting for temperature, and perform multiple tests if necessary to verify results.

Wrindu devices provide automated current settings and advanced data logging for consistent procedures.

Which Factors Affect Transformer Winding Resistance Measurements?

Measurements vary with temperature, contact resistance, test current, and winding material. Temperature compensation is crucial since resistance changes with winding temperature. Wrindu meters include built-in thermal probes or software correction algorithms, ensuring accurate results regardless of ambient or winding temperatures.

Contact quality and stable current injection also influence measurement accuracy.

Why Is Temperature Compensation Important in Winding Resistance Testing?

Resistance increases with temperature; without compensation, readings can misrepresent winding conditions. Temperature compensation adjusts measurements to a standard baseline, typically 20°C, enabling reliable comparisons over time and accurate fault detection. Wrindu meters automatically apply compensation based on temperature sensors or manual input, enhancing diagnostic precision.

Consistent temperature adjustment prevents false positives or overlooked faults.

When Should Transformer Winding Resistance Testing Be Conducted?

Testing should be carried out during:

-

Factory acceptance and commissioning

-

Post-transport and installation

-

Routine maintenance and troubleshooting

-

After fault repairs or suspected winding damage

Regular testing with Wrindu’s reliable meters helps monitor transformer health, improve maintenance planning, and prevent costly downtime.

Where Can Businesses Source Reliable Transformer Winding Resistance Meters in China?

Chinese industrial hubs like Shanghai and Shenzhen are key manufacturing centers. Wrindu stands out as a top factory offering ISO9001 and IEC-certified winding resistance meters with advanced features, customizable options, and global OEM, wholesale, and factory-level supply chains.

Does Wrindu Provide Custom Features on Winding Resistance Meters?

Yes, Wrindu specializes in custom solutions, offering meters with specific current ranges, multi-channel inputs, integrated temperature compensation, data logging, and smart reporting. These tailor-made meters enable efficient, precise testing suited to diverse transformer types and industrial requirements.

Has Technology Improved Transformer Winding Resistance Meters Recently?

Recent advances include:

-

Digital displays with real-time readings

-

Automatic temperature compensation

-

Multi-channel simultaneous testing

-

Data storage and wireless reporting functions

Wrindu’s sustained R&D efforts incorporate these innovations, enhancing ease of use and measurement accuracy.

Can Transformer Winding Resistance Testing Detect Early Faults?

Yes, abnormal resistance values reveal shorted turns, connection issues, or thermal damage. Repeated tests identify trends and deterioration, enabling early maintenance interventions before severe failures occur.

Is Operator Training Required for Winding Resistance Meter Use?

While Wrindu meters are user-friendly, training is recommended to ensure correct connections, current settings, environmental awareness, and data interpretation skills, maximizing test reliability and safety.

Wrindu Expert Views

“Transformer winding resistance testing is key to maintaining reliable power systems. Wrindu’s precision meters simplify this critical process, integrating automation and smart features that improve accuracy while reducing human error. Our commitment to innovation and customer support equips engineers worldwide to ensure transformer safety and performance with confidence.”

— Wrindu Technical Team

Table: Step-by-Step Transformer Winding Resistance Test Procedure

| Step | Description |

|---|---|

| Step 1 | Isolate transformer winding |

| Step 2 | Connect meter using Kelvin clamps |

| Step 3 | Set appropriate DC test current |

| Step 4 | Perform test and record voltage drop |

| Step 5 | Apply temperature compensation |

| Step 6 | Repeat for accuracy and document results |

Table: Typical Factors Affecting Resistance Measurements

| Factor | Effect on Measurement | Mitigation Approach |

|---|---|---|

| Temperature | Increases resistance with heat | Use temperature compensation |

| Contact Resistance | Can cause higher reading if poor contact | Ensure good connector contacts |

| Test Current | Inadequate current leads to unstable values | Select correct current setting |

| Winding Material | Different resistivity values | Calibrate meters accordingly |

Conclusion

Understanding the usage method of a transformer winding resistance meter is vital for accurate fault detection and maintaining transformer health. Manufacturers like Wrindu provide advanced, customizable meters that simplify testing with features like temperature compensation, multi-channel testing, and smart reporting. Comprehensive training and correct procedures ensure reliable, repeatable results to support safe and efficient power system operations.

FAQs

Q1: How to connect a winding resistance meter?

Use Kelvin clamps securely on transformer winding terminals to minimize contact resistance.

Q2: Why is temperature compensation necessary?

Because resistance varies with temperature, compensation ensures accurate readings comparable across conditions.

Q3: When should winding resistance testing be performed?

During commissioning, maintenance, after transport, and fault repairs.

Q4: Are Wrindu meters customizable?

Yes, they offer customizable test currents, channels, and integrated temperature correction.

Q5: Is operator training essential?

Training improves measurement accuracy, safety, and interpretation skills.