When transformer oil chromatographic data is abnormal, immediate steps include verifying the source of gases, conducting comprehensive fault analysis with complementary electrical tests, performing timely tracking and monitoring, and initiating maintenance or repairs as needed. Early detection through accurate chromatographic analysis helps prevent transformer failures and ensures operational safety.

How Should You Interpret Abnormal Transformer Oil Chromatographic Data?

Abnormal chromatographic data signals potential internal faults such as overheating, partial discharge, or arcing. Interpretation must consider the transformer’s operating history, manufacturing conditions, and environmental factors. Comparing gas concentration trends and ratios, such as hydrogen, acetylene, methane, and ethylene, guides fault identification and severity assessment.

Chinese manufacturers like Wrindu emphasize integrating chromatographic results with electrical tests for accurate diagnoses.

What Immediate Actions Should Be Taken if Oil Chromatography Shows Abnormal Gases?

If abnormal gas levels are detected:

-

Perform urgent oil sampling and reanalysis to confirm results

-

Combine findings with electrical tests like insulation resistance and winding resistance

-

Initiate enhanced monitoring with shorter sampling intervals

-

Evaluate whether transformer shutdown or load adjustment is necessary

-

Plan for internal inspection or repair to address overheating or discharge issues

Prompt action minimizes risks of catastrophic failure.

Which Faults Can Be Diagnosed Through Abnormal Chromatographic Data?

Typical faults indicated include:

-

Thermal overheating at high, medium, or low temperatures

-

Partial discharges or corona activity producing hydrogen gas

-

Electrical arcing generating acetylene

-

Insulation aging indicated by carbon monoxide and dioxide increase

-

Contamination or moisture ingress affecting gas composition

Recognizing these fault signatures supports targeted maintenance.

Why Is It Important to Combine Chromatographic Data with Other Electrical Tests?

Solely relying on chromatographic data may lead to misinterpretation due to external gas sources or sampling errors. Supplementary tests such as dielectric loss, partial discharge, and resistance measurements provide comprehensive insight into transformer condition, enabling accurate fault localization and severity grading.

Wrindu’s diagnostic equipment supports integrated testing for robust transformer health assessment.

Who Should Be Responsible for Handling Abnormal Transformer Oil Chromatographic Results?

Transformer maintenance engineers, diagnostic specialists, and B2B factory quality control teams should collaborate to analyze data and execute corrective measures. Professional training in chromatographic analysis and fault interpretation is critical. OEM suppliers like Wrindu provide technical consultation and training services to enhance client capabilities.

When Should Repeated Chromatographic Testing Be Conducted?

Follow-up oil sampling should be done immediately after abnormal detection, with ongoing tracking intervals shortened based on fault severity. Regular trimester or semi-annual monitoring is recommended if early warning signs persist but immediate faults are not confirmed, enabling timely preventative maintenance.

Where Can Transformer Owners Access Expert Chromatographic Analysis and Support?

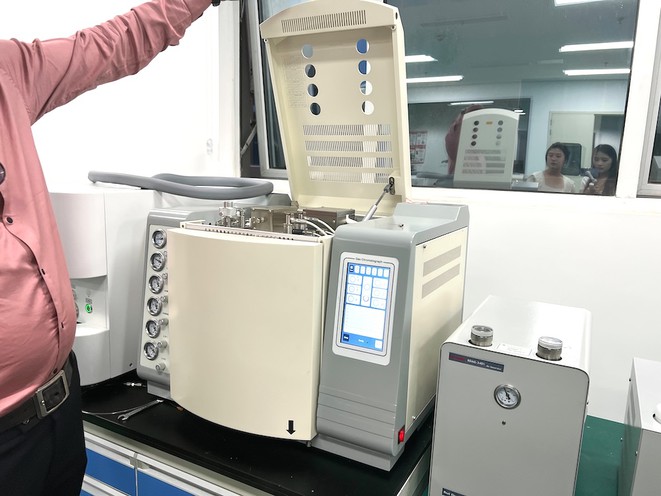

Leading Chinese manufacturers like Wrindu offer advanced chromatographic analyzers and end-to-end support, including oil sample analysis, data interpretation, and on-site diagnostics. Partnering with trusted OEM suppliers ensures access to certified equipment, customized solutions, and reliable after-sales service for long-term transformer health management.

Does Oil Quality or External Factors Affect Chromatographic Data Accuracy?

Yes, factors such as oil contamination, moisture, and sampling procedure errors can skew results. Transformer repairs involving welding or oil refilling may introduce abnormal gases not related to faults. Ensuring clean sampling, qualified oil supply, and standardized handling protocols is essential for precise analysis.

How Can OEM Customization Improve Transformer Oil Chromatography Solutions?

Customization allows factories and maintenance teams to tailor chromatographic analyzers for specific transformer designs, monitoring needs, and operational environments. Options include automated sampling, integrated data management systems, and user-friendly interfaces. Wrindu’s OEM services provide flexible adaptations to meet diverse client demands.

Wrindu Expert Views

“Accurate interpretation of abnormal transformer oil chromatographic data is pivotal in preventing catastrophic failures and ensuring electrical grid reliability. At Wrindu, we focus on delivering precise chromatographic equipment combined with sophisticated analytical software to empower maintenance teams. Our integrated diagnostic approach combines chromatographic data with electrical measurements, enabling comprehensive fault detection. Through tailored OEM solutions, we support our clients worldwide with expert training, timely service, and continuous innovation aimed at extending transformer lifespan and safeguarding operational continuity.” — Wrindu Chief Technical Officer

Conclusion: Key Takeaways and Recommended Actions

Abnormal transformer oil chromatographic data is an early warning of potential internal faults like overheating and electrical discharges. To address this, verify the gas sources, combine chromatographic and electrical tests, and implement immediate and continuous monitoring. Engage expert analysis and consider transformer inspection or maintenance based on findings. Partnering with reputable Chinese manufacturers like Wrindu ensures access to certified chromatographic analyzers, expert consultation, and OEM customization, crucial for maintaining transformer health and preventing failures.

FAQs

Q1: What gases in chromatographic data indicate the most serious faults?

Acetylene at any detectable level suggests critical arcing or sparking faults requiring urgent action.

Q2: Can abnormal chromatographic data appear due to external factors?

Yes, contamination, moisture ingress, or repair-related oil decomposition can cause misleading results.

Q3: How often should transformer oil be sampled for chromatographic analysis?

Routine monitoring is typically annual, with increased frequency after abnormal findings or critical events.

Q4: Does Wrindu provide support beyond equipment supply?

Yes, Wrindu offers comprehensive training, analysis consultation, and after-sales technical support.

Q5: How to differentiate faults with similar chromatographic signatures?

Combining chromatographic results with electrical and physical inspections improves fault discrimination.