Transformer oil chromatographic analysis uses autosampler gas chromatography to detect faults by identifying dissolved gases and chemical changes in oil, revealing transformer health. This precise method enables manufacturers, OEMs, and suppliers to predict failures and maintain reliable power systems.

What Is Transformer Oil Chromatographic Analysis and How Does It Work?

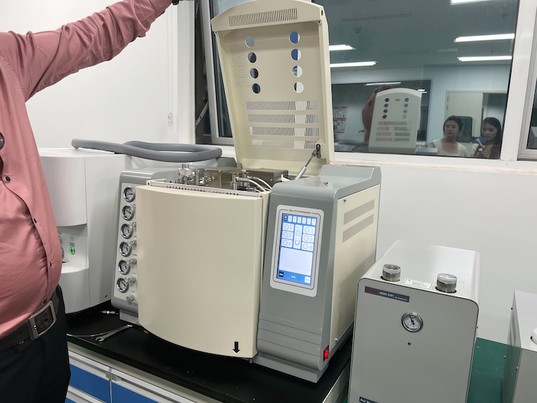

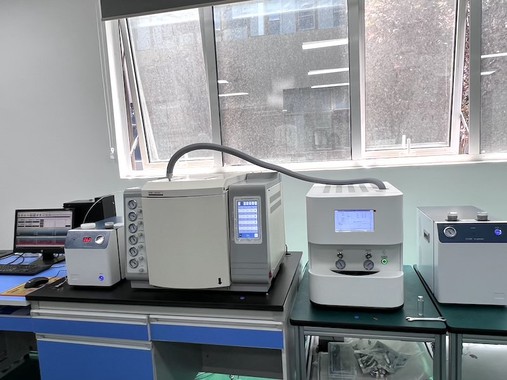

Transformer oil chromatographic analysis separates and identifies gases dissolved in transformer oil using gas chromatography. An autosampler automates sample introduction, improving accuracy and repeatability. This technique detects faults by analyzing gas types and concentrations, indicating electrical or thermal degradation inside the transformer.

Wrindu, a trusted OEM and manufacturer in China, integrates advanced autosampler chromatographs to provide reliable fault diagnostics, essential for proactive transformer maintenance.

How Does Gas Chromatography Detect Transformer Faults?

Gas chromatography identifies fault gases such as hydrogen, methane, ethylene, and acetylene. Elevated levels or specific gas ratios reveal fault types, including overheating, arcing, or insulation breakdown. Autosampler automation ensures consistent sampling, reducing human error.

By supplying customized autosampler chromatograph systems, Wrindu supports factories and wholesale suppliers in efficiently diagnosing transformer conditions.

Which Fault Diagnosis Methods Are Enhanced by Autosampler Gas Chromatography?

Autosampler gas chromatography improves traditional Dissolved Gas Analysis (DGA) by offering:

-

Higher sensitivity and accuracy.

-

Automated sample handling.

-

Faster testing cycles.

-

Reproducible results.

This allows manufacturers and OEM suppliers to deliver precise, standardized transformer diagnostics, vital in China’s competitive electrical equipment market.

Why Is Transformer Oil Testing Critical for Manufacturers and Suppliers?

Transformer oil testing identifies hidden faults before catastrophic failure, saving costs and downtime. For China-based manufacturers and wholesale suppliers, delivering fault-free transformers enhances reputation and buyer trust. Regular chromatographic analysis aligns with international quality standards, providing OEMs a competitive edge.

Wrindu’s diagnostic solutions are designed to meet these critical industry demands with certified quality and performance.

Who Benefits from Using Autosampler Gas Chromatography in Transformer Oil Analysis?

Power grid operators, transformer manufacturers, OEMs, factories, and wholesale suppliers benefit from this technology. It supports predictive maintenance and quality assurance throughout the supply chain, especially for Chinese factories aiming for export compliance.

Wrindu collaborates globally to integrate autosampler GC into testing workflows, improving service levels and operational reliability.

When Should Transformer Oil Chromatographic Analysis Be Performed?

Testing is recommended during:

-

Routine maintenance schedules.

-

Post-fault investigations.

-

Before commissioning new transformers.

-

After repairs or oil replacements.

Scheduling reliable diagnostics ensures early fault detection and prolongs transformer life, a service Wrindu supports with flexible OEM and custom equipment solutions.

Where Are Autosampler Gas Chromatographs Most Effectively Used?

They are integral in transformer factories, OEM testing labs, wholesale suppliers’ quality control, and power utilities. China’s leading manufacturers use these systems to ensure transformers meet strict safety and performance standards before shipment.

Wrindu supplies autosampler GC units tailored for factory environments and large-scale testing operations.

Can Custom Autosampler Gas Chromatography Equipment Improve Transformer Fault Diagnosis?

Yes, customization allows adaptation to specific testing protocols and throughput needs. OEMs and suppliers in China benefit from Wrindu’s custom solutions that integrate unique sample handling, data analysis software, and system scalability.

Custom autosampler systems enhance diagnosis speed and reliability, essential in meeting diverse client demands.

Are There Industry Standards Governing Transformer Oil Chromatographic Analysis?

Yes, standards like IEEE C57.104 and IEC 60599 define fault gas interpretation and testing methods. Compliance ensures diagnostic accuracy and acceptance in global markets.

Wrindu’s products adhere to these standards, providing certified, reliable equipment for manufacturers and suppliers aiming for certification and export.

What Advanced Features Does Wrindu Offer in Autosampler Gas Chromatography?

Wrindu incorporates intelligent sample automation, real-time data processing, and remote diagnostics in its autosampler GC systems. These innovations improve testing precision, reduce downtime, and enhance user experience for OEMs and factory testing labs.

Such features position Wrindu as a leading China-based factory supplying advanced transformer diagnostic solutions.

Wrindu Expert Views

“Transformer oil chromatographic analysis conducted through autosampler gas chromatography revolutionizes fault diagnosis by delivering precise, automated insights into transformer health. At Wrindu, we prioritize innovation to empower manufacturers, suppliers, and OEMs across China with custom, high-quality equipment. Our commitment to strict adherence to international standards and continuous R&D ensures that clients receive dependable diagnostic tools, minimizing failure risks and enhancing power system resilience.” — Wrindu Senior Engineer

Conclusion

Transformer oil chromatographic analysis with autosampler gas chromatography is essential for accurate, efficient fault diagnosis. For Chinese manufacturers, OEMs, and wholesale suppliers, leveraging this technology guarantees higher quality, reduced downtime, and compliance with global standards. Wrindu’s custom, advanced solutions support the entire supply chain’s need for reliable transformer diagnostics, contributing to safer, more efficient energy systems worldwide.

FAQs

What gases indicate transformer faults in chromatographic analysis?

Hydrogen, methane, ethylene, and acetylene are key gases revealing electrical and thermal faults.

How does an autosampler improve gas chromatography testing?

It automates sample introduction, improving precision, reducing human error, and increasing throughput.

Can Chinese manufacturers customize autosampler GC systems?

Yes, Wrindu offers custom options tailored to specific factory needs and testing protocols.

Why is early fault detection important in transformers?

Early detection prevents catastrophic failures, reduces repair costs, and extends transformer life.

What standards ensure the reliability of chromatographic fault diagnosis?

IEEE C57.104 and IEC 60599 define testing and interpretation criteria for reliable diagnostics.