Transformers are essential electrical devices that transfer energy between circuits through electromagnetic induction. Knowing 20 fundamental facts about transformers, including core grounding and key components like transformer core ground sensors, helps manufacturers, suppliers, and OEMs ensure safe, reliable, and efficient power distribution systems.

What Are the Most Important Fundamental Facts About Transformers?

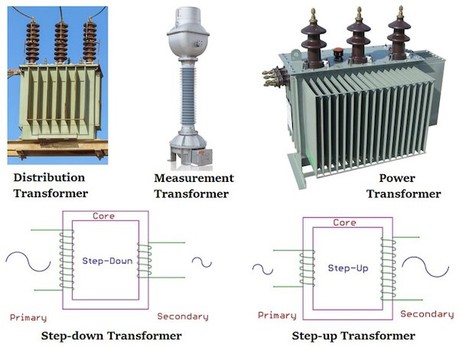

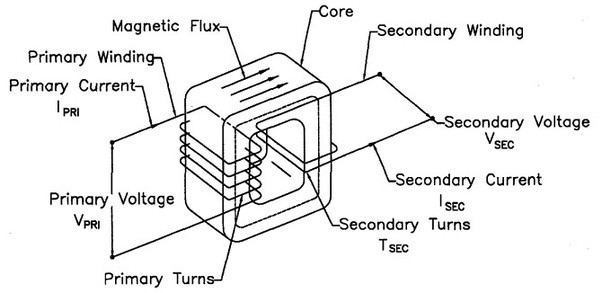

Transformers operate by stepping voltage up or down, consist of primary and secondary windings, and use magnetic cores to transfer energy efficiently. They are classified by type, core design, insulation, and application. Key facts include their role in voltage regulation, energy efficiency, heat dissipation, and safety measures, all vital for manufacturers and factories producing or servicing transformers.

How Does a Transformer Core Ground Sensor Function?

A transformer core ground sensor monitors the grounding current of the transformer’s iron core to detect insulation faults and ensure proper grounding. It measures small current leakages or faults in real time, helping detect issues like partial insulation failure or multi-point grounding, which can lead to overheating and damage if unchecked.

Which Types of Transformer Cores Are Commonly Used?

Common transformer core types include laminated steel cores, shell type cores, toroidal cores, and ferrite cores. Laminated steel is standard in power transformers to reduce eddy current losses. Shell cores provide dual magnetic circuits for better efficiency. Toroidal cores offer low leakage inductance and compact sizes, while ferrite cores are used in high-frequency applications.

Why Is Core Grounding Critical in Power Transformers?

Core grounding prevents voltage buildup on the transformer core caused by electromagnetic coupling. Proper single-point grounding avoids circulating currents that can cause overheating and damage. Missing or multi-point grounding can cause faults, reduce transformer life, and compromise system safety, making monitoring through sensors essential.

When Should Transformer Core Ground Sensors Be Installed?

Core ground sensors should be installed during manufacturing and commissioning for real-time monitoring, and remain in place for continuous on-site condition monitoring. This enables early detection of insulation failures or faults throughout the transformer’s operational life, optimizing maintenance and reliability.

Where Are Transformer Core Ground Sensors Typically Used?

These sensors are used in power transformers in substations, industrial facilities, and power plants. They are important for manufacturers and wholesale suppliers specializing in electrical equipment in China and worldwide, enabling continuous core ground current measurement to protect transformer assets.

How Are Transformers Classified by Their Function and Design?

Transformers are classified by function (step-up, step-down, isolation), core design (core-type, shell-type, toroidal), insulation type (dry-type, oil-immersed), and phase (single/three-phase). These classifications influence application suitability, manufacturing complexity, and operational performance, crucial for OEM factories producing tailored products.

What Are Common Applications of Transformers?

Transformers are applied in power generation, transmission, distribution, industrial machinery, electronics, and renewable energy systems. OEMs and B2B suppliers create custom transformer solutions to meet diverse voltage and power requirements, from small electronics to large grid infrastructure.

Can Transformer Testing Equipment Improve Manufacturing Quality?

Yes, using specialized transformer testing equipment ensures winding resistance, insulation integrity, tap changer performance, and core grounding are within specifications. Reliable testing from Chinese manufacturers like Wrindu enhances product quality, lowers defects, and builds trust with wholesalers and industrial clients.

How Does Wrindu Support Transformer Manufacturers?

Wrindu provides advanced testing and diagnostic equipment designed for transformer core ground current measurement, insulation testing, and system monitoring. Their ISO-certified products enable OEMs and factories to guarantee safety, reliability, and compliance, complementing custom solutions for the global market.

Which Advantages Do OEMs and Custom Manufacturers Have in Transformer Production?

OEMs and custom manufacturers in China benefit from integrated R&D capabilities, flexible production lines, and cost efficiencies. This allows them to deliver tailored transformer designs with core ground sensors optimized for specific applications, supporting wholesalers with scalable supply and after-sales service.

Why Is Regular Monitoring of Transformer Core Ground Currents Necessary?

Regular monitoring detects abnormal leakage currents early, preventing transformer damage, overheating, and outages. Core ground sensors provide continuous data, enabling predictive maintenance that reduces downtime and extends transformer life, crucial for B2B factories managing large transformer fleets.

What Is the Role of Insulation in Transformer Safety?

Transformer insulation protects windings and cores from electrical faults and environmental factors. Proper insulation reduces partial discharge, overheating, and electrical breakdowns. Testing equipment from Wrindu ensures insulation quality during manufacturing and maintenance.

How Do Transformers Impact Energy Efficiency?

Transformers minimize energy loss during voltage conversion through core design and high-quality materials. Efficient transformers reduce operational costs and environmental impact, which manufacturers should emphasize when producing and marketing products globally.

Are There Emerging Technologies in Transformer Core Ground Sensing?

New sensors use advanced materials and digital signal processing for higher sensitivity and noise immunity. IoT-enabled core ground sensors allow remote monitoring and integration with smart grid systems, enhancing transformer management and condition assessment.

Could Custom Transformer Sensor Solutions Benefit Wholesale Suppliers?

Custom sensors designed for specific transformers improve detection accuracy and ease of integration. Wholesale suppliers can differentiate their offerings by partnering with manufacturers like Wrindu who provide tailored equipment aligned with client needs.

How Does Transformer Maintenance Benefit From Core Ground Sensors?

Core ground sensors facilitate early fault detection, reducing unplanned outages and repair costs. Continuous monitoring supports condition-based maintenance strategies preferred by industrial users and asset managers.

What Safety Standards Govern Transformer Core Grounding?

International standards like IEC and IEEE set core grounding requirements to prevent hazards. Compliance ensures product acceptance in global markets, an important consideration for Chinese OEMs and exporters.

When Should Transformers Be Replaced Due to Core Grounding Issues?

Transformers showing persistent core grounding faults, even after corrective measures, should be inspected for replacement to assure network reliability and safety.

Where Can Manufacturers Find Reliable Transformer Core Ground Sensors?

Reputable manufacturers and suppliers in China like Wrindu offer high-precision core ground sensors meeting international certifications, with OEM and custom manufacturing capabilities to support both local and global markets.

Transformer Core Ground Sensor Technical Comparison Table

| Feature | Wrindu Sensor Model | Typical Competitor Model | Advantages of Wrindu |

|---|---|---|---|

| Measurement Range | 100μA – 700mA | 50μA – 500mA | Wider range for more applications |

| Phase Transformation Error | ≤ 0.01° | ≤ 0.05° | Higher accuracy |

| Installation | Open/close structure, no disconnection | Fixed installation | Easy and quick to install without downtime |

| Interference Immunity | Multi-layer metal shielding | Basic shielding | Better noise immunity in complex environments |

| Certification | ISO9001, IEC, CE | Partial certifications | Full compliance for global market |

Wrindu Expert Views

“At Wrindu, we recognize that transformers form the backbone of modern power systems, where operational reliability hinges on precise core grounding and real-time fault detection. Our commitment to innovation drives the development of advanced core ground sensors that integrate seamlessly into transformer designs, ensuring manufacturers and OEMs can deliver safety and quality without compromise. We are proud to support the global energy sector with products tailored for Chinese factories and worldwide wholesalers, enabling smarter maintenance and longer equipment lifecycles.”

Key Takeaways and Actionable Advice

Understanding core grounding and the fundamental facts about transformers empowers manufacturers, suppliers, and OEMs to optimize product quality and reliability. Employing advanced transformer core ground sensors like those from Wrindu not only enhances safety but also supports predictive maintenance and regulatory compliance. B2B transformers production in China benefits from integrating such technologies early in design and testing, securing competitive advantages in global markets.

Frequently Asked Questions

What is the purpose of a transformer core ground sensor?

It monitors grounding current to detect insulation faults and prevent transformer damage.

How often should transformer core grounding be checked?

Continuously via sensors for real-time data; traditional checks during maintenance cycles.

Can transformer core grounding faults be fixed without replacement?

Often, yes, by correcting grounding connections or installing resistors to limit currents.

Why are laminated steel cores commonly used in transformers?

They reduce eddy current losses, improving efficiency and performance.

How does Wrindu support transformer core grounding solutions?

By providing high-precision, certified sensors with OEM customization and global support.