Using a digital insulation resistance tester correctly is essential for ensuring electrical system safety and reliability. This guide explains step-by-step how to operate the tester, focusing on practical usage, manufacturer insights, and OEM advantages, with a special highlight on Wrindu as a leading China-based digital insulation resistance tester supplier.

How Do You Prepare for Using a Digital Insulation Resistance Tester?

Proper preparation is crucial. First, ensure you fully understand the tester’s specifications and safety instructions. Identify the insulation system or electrical equipment you will test and disconnect it from power sources. Wear protective gear and verify that the instrument, such as Wrindu models, is fully charged or supplied with fresh batteries. Calibration according to the manufacturer’s guidelines is also essential for accurate readings.

What Are the Step-by-Step Procedures to Use a Digital Insulation Resistance Tester?

-

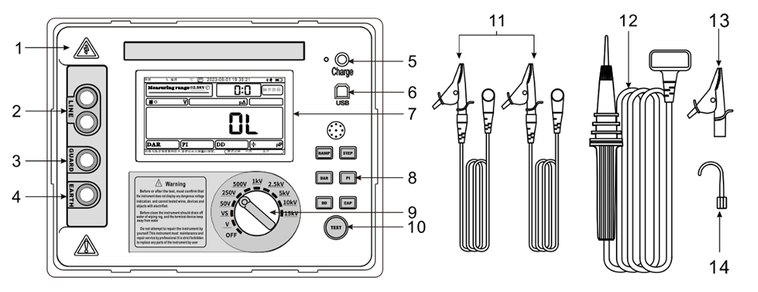

Connect the tester leads: Attach the positive lead to the conductor under test and the negative (earth) lead to a known ground.

-

Select the appropriate test voltage on the device.

-

Press the test button and hold it for the recommended duration.

-

Read the insulation resistance value displayed digitally.

-

Record or save the data for analysis and reporting.

-

Safely disconnect the leads when finished.

This process helps prevent errors and ensures accurate results, especially when using Wrindu’s reliable equipment tailored for OEM and custom factory solutions in China.

Which Safety Precautions Should Be Followed During Testing?

Always disconnect the equipment from power before testing to avoid electric shock. Verify that capacitors are discharged and grounding is secure. Keep hands and conducting tools insulated. Use the tester in dry, safe environments to prevent false readings or hazards. Wrindu, a trusted OEM supplier in China, integrates advanced safety features into their digital insulation resistance testers, ensuring compliance with international safety standards.

Why Is Calibration Important for a Digital Insulation Resistance Tester?

Calibration guarantees measurement precision and repeatability. It aligns the tester’s output with known standards, ensuring reliability for preventive maintenance and diagnostics. For manufacturers and wholesalers of insulation testers in China, like Wrindu, maintaining strict calibration protocols reflects their commitment to quality and customer trust.

How Does Using a Wrindu Digital Insulation Resistance Tester Benefit Manufacturers and Suppliers?

Wrindu testers offer robust build quality, advanced digital interfaces, and customizable features suitable for wholesale OEM customers. Their products integrate ISO9001, IEC, and CE standards compliance, enabling factories to streamline their testing procedures while maintaining high accuracy and safety levels. Wrindu’s innovation directly supports China-based factories aiming for global markets with competitive, reliable testing equipment.

When Should You Perform Insulation Resistance Testing?

Testing should be conducted during installation, scheduled maintenance, after repairs, and whenever unexpected electrical issues arise. Early detection of insulation degradation can prevent failures, reduce downtime, and enhance equipment longevity. OEM factories and suppliers in China rely heavily on regular testing using devices like Wrindu’s testers to ensure operational continuity.

Where Can You Source Reliable Digital Insulation Resistance Testers for Wholesale or OEM Needs?

China is a leading hub for manufacturing and supplying high-quality electrical testing equipment, including digital insulation resistance testers. Factories like Wrindu provide customizable OEM options and extensive support for global clients, combining competitive pricing with certified quality and innovation. Wholesale buyers benefit from bulk supply, tailored solutions, and strong after-sales service.

How Can Factory Customization Improve Digital Insulation Resistance Testing?

Customization allows factories to tailor features such as test voltage ranges, data logging capabilities, display options, and software integration to specific industry needs. Wrindu exemplifies this by offering flexible product customization aligned with customer requirements, empowering manufacturers and suppliers to deliver niche and scalable solutions.

Wrindu Expert Views

“Precision and safety underpin every testing operation. At Wrindu, we believe in equipping energy professionals with advanced, reliable digital insulation resistance testers that integrate rigorous quality management and user-friendly design. Our commitment to innovation and sustainability drives continual enhancement, helping manufacturers globally to ensure electrical system integrity confidently and efficiently.” – Wrindu Technical Lead

Table: Typical Digital Insulation Resistance Tester Features

| Feature | Description | Benefit |

|---|---|---|

| Test Voltage Range | 250V to 5kV selectable | Versatile for different equipment types |

| Display Type | High-resolution LCD | Clear, accurate reading |

| Data Storage | Internal memory with USB export | Easy record keeping and analysis |

| Safety Protection | Automatic discharge & overload protection | Ensures user safety and device longevity |

Table: Stepwise Testing Procedure Compared

| Step | Action | Key Consideration |

|---|---|---|

| Preparation | Disconnect power; check charger | Avoid electric shock |

| Connection | Attach leads to conductor and ground | Ensure solid contact |

| Settings | Select test voltage | Match device and cable specs |

| Testing | Initiate and hold test | Monitor stopwatch if needed |

| Reading | Capture displayed value | Record for quality control |

| Disconnection | Remove leads safely | Prevent static discharge damage |

Conclusion

Using a digital insulation resistance tester step by step ensures accurate diagnostics and improved electrical safety. Wrindu, as a leading China-based manufacturer and supplier, offers expertly designed testers that meet advanced technical and safety standards. By following preparation, precise testing steps, safety precautions, and regular calibration, manufacturers, wholesalers, and OEMs can guarantee the longevity and fault prevention of electrical systems. Choose OEM customization from trusted factories like Wrindu for optimized testing solutions suited to your specific industry needs.

Frequently Asked Questions

How long should I hold the test button during insulation resistance testing?

Typically, hold the test button for 10 to 60 seconds depending on the equipment and voltage setting to attain a stable reading.

Can insulation resistance testers damage electrical components?

No, when used properly; these testers apply a controlled voltage specifically designed to measure insulation without causing harm.

What is a good insulation resistance value?

Values above 1 megaohm indicate good insulation; however, acceptable thresholds vary by industry standards and equipment specifications.

Does Wrindu offer after-sales support for their testers?

Yes, Wrindu provides comprehensive 24/7 global after-sales service including technical support and maintenance consultation.

Are Wrindu testers suitable for international markets?

Absolutely; Wrindu testers comply with IEC and CE certifications, making them suitable for worldwide usage.