OVERVIEW

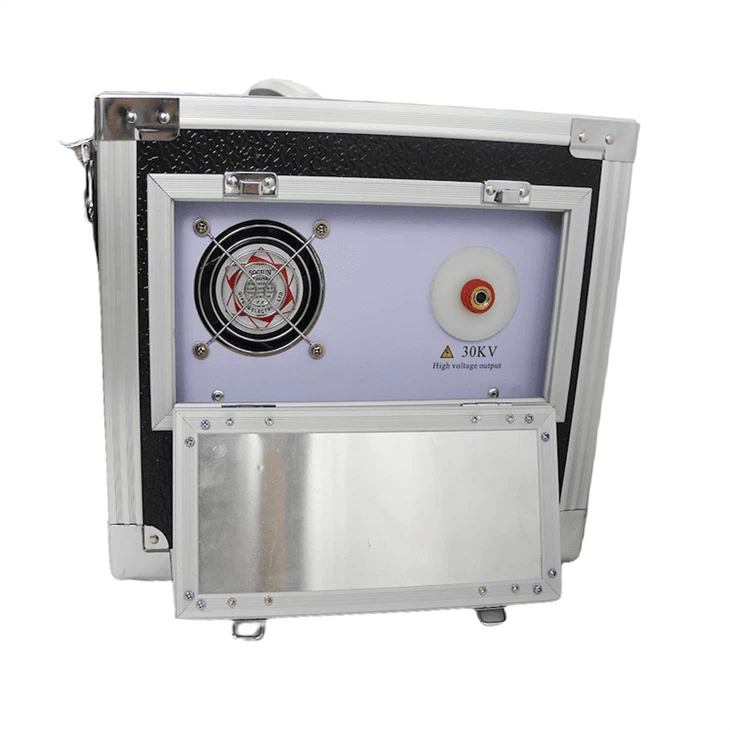

Among the many methods for judging whether the vacuum degree of vacuum tubes has deteriorated, the power frequency withstands voltage method is the more commonly used one. However, this method has limitations, and the arc extinguishing chamber can only be judged by severely deteriorated vacuum degrees. When the vacuum degree drops to the range of 10⁻² ~ 10⁻¹ Pa, although the breakdown voltage of the arc extinguishing chamber has not yet decreased, its actual performance no longer meets the standard requirements. The RDZK-IV vacuum interrupter tester developed by our company adopts an innovative technical solution. The instrument uses an excitation coil to accurately measure the vacuum degree of the arc extinguishing chamber based on the principle of magnetron discharge. Disassembling the arc extinguishing chamber is unnecessary, effectively avoiding equipment damage and other risks caused by disassembly. At the same time, the instrument integrates an advanced microcomputer control system for synchronous control and data collection and processing, which significantly improves the sensitivity of on-site testing and can accurately detect vacuum degree changes as low as 10⁻⁵ Pa.

The RDZK-IV vacuum interrupter tester’s significant advantage lies in its unique excitation coil application and efficient data processing method, which successfully realizes the non-disassembly measurement of vacuum degree. In addition, the instrument is easy to operate and use, has high test accuracy, and is efficient testing equipment. It can play an important role in industries such as electricity, steel, petrochemicals, textiles, coal, and railways, where vacuum switches are widely used, providing strong guarantees for the safe and stable operation of related equipment.

CHARACTERISTIC

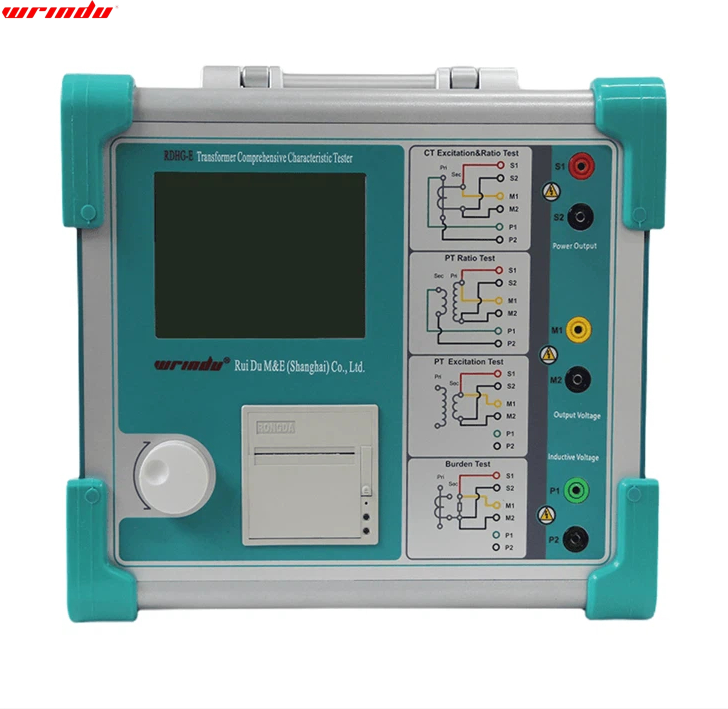

• The vacuum interrupter tester can accurately and quantitatively measure the vacuum degree of various types of vacuum switch arc extinguishing chambers;

• When measuring on-site, there is no need to disassemble the vacuum switch, which is easy to operate;

• The test results are accurate and reliable, ensuring efficient work;

• Equipped with an LCD, it provides a more intuitive and easy-to-use operation experience;

• It supports data storage, printing, and query, which is convenient for subsequent management and analysis;

• The vacuum interrupter tester is light, compact, easy to carry, and suitable for various occasions.

For more information about circuit breaker testing equipment, please click More.

To request the latest quotes, please click Contact Us.

FAQ

Q: What is a vacuum interrupter tester?

A: The VIDAR vacuum interrupter tester facilitates a rapid and convenient assessment of vacuum interrupter integrity through the established correlation between flashover voltage and the interrupter. By applying a suitable test voltage (DC) to the breaker, the results are promptly obtained, providing an efficient means of evaluating the vacuum interrupter’s condition.

Q: What is the difference between a vacuum interrupter and a vacuum circuit breaker?

A: A vacuum interrupter is a component designed to extinguish electrical arcs in a vacuum environment. A vacuum circuit breaker is a complete switching device that uses vacuum interrupters to control and protect electrical circuits by interrupting current flow during faults. In essence, the vacuum interrupter is the arc-quenching part within the vacuum circuit breaker.

Q: How do you test a vacuum bottle?

A: Testing a vacuum bottle involves several methods:

1. Pressure Decay Test:

– Evacuate and seal the bottle, and monitor pressure for leaks.

2. Helium Leak Detection:

– Introduce helium and use a spectrometer to find leaks.

3. High Voltage Testing:

– Apply high voltage to check for breakdowns or flashovers.

4. Thermal Performance Test:

– Subject to temperature variations, assess vacuum maintenance.

5. Visual Inspection:

– Inspect for physical damage, corrosion, or abnormalities.

6. X-ray Inspection:

– Use X-ray to examine internal structure for defects.