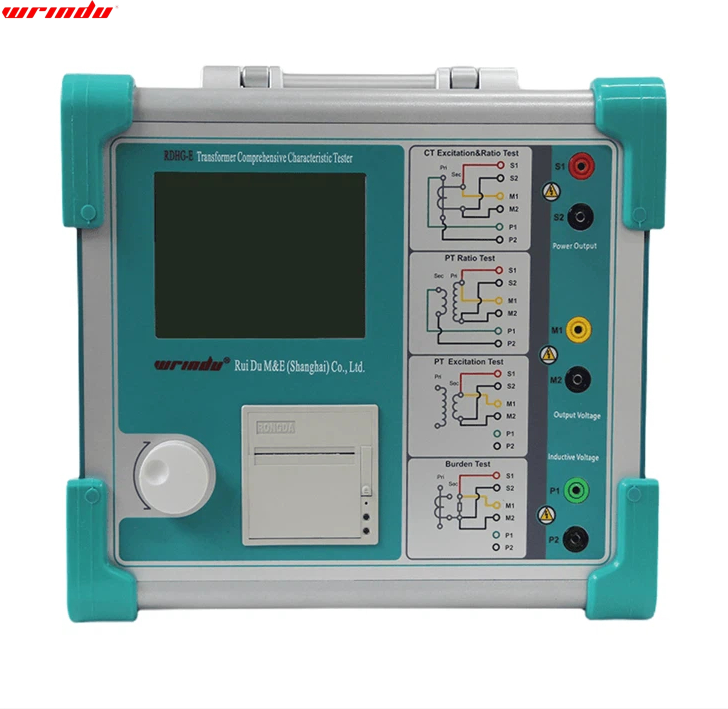

Power transformer testing

RuiDu Mechanical: Your Reliable Transformer Testing Equipment Supplier!

RuiDu Mechanical and Electrical (Shanghai) Co., Ltd. is a leading global power testing equipment manufacturer and system solution provider. Our company was established in 2014. Our main products are substation transformers, high-voltage switches, transformers, lightning arresters, batteries, cable faults, relay protection, insulation withstand voltage, transformer oil injection equipment, etc. Our factory covering an area of more than 50,000 square meters, 6 product production lines and more than 200 employees, selling the products to more than 120 countries and regions. In addition, we support high-volume production, calibrate and test instruments at the point of sale, providing repair instructions for these products.

Rich Experienced

Our team has more than 10 years of experience in the industry, providing customers with compliant, high-quality equipment, and developing friendly cooperation with partners such as Kenya Power, UETCL, TCN, EVN, PLN, NGCP, CFE.

Rich Experienced

Our team has more than 10 years of experience in the industry, providing customers with compliant, high-quality equipment, and developing friendly cooperation with partners such as Kenya Power, UETCL, TCN, EVN, PLN, NGCP, CFE.

Rich Experienced

Our team has more than 10 years of experience in the industry, providing customers with compliant, high-quality equipment, and developing friendly cooperation with partners such as Kenya Power, UETCL, TCN, EVN, PLN, NGCP, CFE.

Rich Experienced

Our team has more than 10 years of experience in the industry, providing customers with compliant, high-quality equipment, and developing friendly cooperation with partners such as Kenya Power, UETCL, TCN, EVN, PLN, NGCP, CFE.

What is Transformer Testing Equipment ?

Transformer testing equipment is used to monitor and test the electrical and mechanical parameters of transformers and related devices. Some examples include:DV Power test instruments, transformer ohmmeters, megger test equipment. Insulation resistance transformer testing, also known as the Megger test, is used to determine the quality of insulation within the transformer itself. These tests are conducted with a megohmmeter, one of the necessary transformer test instruments, that operates similar to a multi-meter. Other applications for megohmmeters include testing the insulation resistance of cable reels, rectifiers, solid-state diodes, and other electrical components.

Features of Transformer Testing Equipment

Wide Compatibility

Our transformer testing equipment offers advanced data upload capabilities via USB connectivity. They also offer a range of software to extend their compatibility, such as Windows/XP/Visits.

HD Display

They are equipped with LCD displays of different sizes that can clearly display various data, such as inter-winding faults of the transformer, incorrect connections, displacements, etc., and provide data recording capabilities for a large number of data points.

Data Protection

These detectors will alert you when the battery is low, allow the user to store values and prepare them for final analysis, and transfer the data stored in the device to a computer via an interface and cable.

Weather Resistant

Our transformer testing equipment is equipped with alloy parts and ABS casings, and is manufactured through sealing to provide high airtightness, which can maintain stable use in extreme working environments and climates.

What are advantages of Grounding And Insulation Resistance Tester ?

01/ Transformer Winding Resistance Tester

A transformer winding resistance tester measures the DC resistance values of transformer windings, rotating machine windings, or any DC resistance of an inductive device. It is used in the manufacturing process for quality control and design verification as well as in the field during installation. The DC Winding Resistance test is a “Continuity Check” that identifies discontinuities, “bad” connections, and open-circuits involving the transformer components.

02/ Transformer Turns Ratio Tester

Transformer Turns Ratio (TTR) is one of the most common test used to assess the condition of the transformer’s windings and core. It is performed as a part of acceptance and maintenance test procedure to determine any problems due to poor design, assembly, handling, overloading, fault conditions or poor maintenance.

03/ Transformer On-load Tap Changer Tester

The on-load tap changer (OLTC) is the only moving part in a typical power transformer, it permits tap changing and regulating voltage without affecting the network operation. While the transformer on-load tap changer tester can identify loose electrical connections and partial open-circuited conditions. It can also measure the voltage drop between each test point.

04/ Transformer Partial Discharge Tester

A transformer partial discharge tester, also known as a PD testing, is a non-destructive method that assesses the health of a transformer’s electrical insulation. The test involves applying a high voltage to the transformer and measuring any partial discharges emitted by the insulation. The test works by measuring the amount of partial discharge in Coulombs between the copper or aluminum conductor and the insulation.

05/ Transformer Power Factor Measuring Instrument

A wattmeter can measure power factor. Power factor is the ratio of real power to apparent power, and is expressed as a percentage or decimal. It is defined as W/VA, and can be measured using the wattmeter-ammeter-voltmeter method. A power factor meter can also measure the power factor of a transmission system. It can determine the types of load used on the line, and calculate the losses that occur on it.

06/ Transformer Short-circuit Impedance Tester

Transformer short-circuit impedance tester is an instrument that tests the short-circuit impedance of transformers. It compares the short-circuit impedance percentage on-site with the value on the nameplate or factory default. This helps identify defects such as winding deformation or displacement. A short-circuit test measures the equivalent series resistance and reactance of a transformer. Series resistance provides information about the transformer’s full load copper losses, while series reactance establishes the transformer’s impedance.

Different Methods for Testing Transformers

For each different type of transformer, the inspector should conduct the specific recommended tests to ensure efficient and safe inspection and operation. Today we’ll be covering four of these methods so that you can have a better idea of the most common testing transformers procedures.

Turns Ratio Testing

Turns ratio transformer testing is commonly used to ensure that the winding ratio between the primary and secondary coils are aligned to recommended specifications. This type of transformer testing also ensures the transformer will provide either step-up or step-down voltage. A step-down transformer, for instance, comprised of 100 primary turns and 10 secondary turns will work to reduce the voltage by a factor of 10 — corresponding to the secondary coil — while multiplying the current by 10 as well.

Insulation Resistance Testing

Insulation resistance transformer testing, also known as the Megger test, is used to determine the quality of insulation within the transformer itself. These tests are conducted with a megohmmeter, one of the necessary transformer test instruments, that operates similar to a multi-meter. In order to pass the test, the insulation of a transformer must be determined to have a greater resistance than defined by international standards for that transformer type. If it measures any lower it could signify an issue with the insulation which may require replacement.

Power Factor Testing

Power factor transformer testing is the process wherein the power loss of the insulation system is tested by measuring the angel the resulting current of power that occurs when AC voltage is applied. For the test results to be optimal, the angle of the current should measure 90 degrees; however, more often than not, insulation is never perfect. As a rule, the closer to 90 that the current is, the better the insulation is.

This test is completed with a power factor test kit, and it can be completed regularly throughout the life of the transformer. This can help detect deteriorating or malfunctioning insulation over time and give you an idea of when the transformer will need to be replaced.

Resistance Testing

This type of transformer testing once a transformer has been left to settle at the same temperature of the surrounding air. The reason for this is to check for any differences between the opens and windings within the transformer. This helps ensure that all the circuits are still wired and connected correctly. This test is conducted using an ohmmeter.

Benefit of Using Transformer Testers

At your industrial site or plant, there are many regular maintenance tests you have to conduct on your electrical equipment as well as any other machinery you run onsite. Whether you are redeveloping your site’s maintenance procedures or trying to gain a handle on how to best manage the operation and efficiency of your electrical equipment.

Extend Lifespan

We have found that regularly performing several standard transformer testing procedures on transformers is an effective, reliable way to gain insight into their condition. This process can extend their lifespan and catch minor issues before major problems develop.

Avoid Damage

For example, mechanical alterations to the windings, contact problems in the tap charger, or shorted windings/coils can be detected earlier on using conventional transformer testing practices. As a result, you can prevent costly damage and avoidable downtime at your site.

Convenient Test

Conventional testing methods we perform during transformer testing include measuring a variety of parameters, such as the magnetizing current, winding resistance, short circuit impedance, and the transformer ratio. This process is generally quick and easy and does not require you to shut down your plant or site for any significant amount of time.

Factors to Consider When Choose Transformer Testing Equipment

When it comes to ensuring the smooth and reliable functioning of transformers, there’s no room for compromise. Transformer testing equipments plays a critical role in maintaining the efficiency and safety of these essential power components. However, with a plethora of options available in the market, choosing the right testing equipment can be a daunting task. We will walk you through the essential considerations and features to help you make an informed decision.

Understanding Your Application

First things first, you must have a clear understanding of your specific application requirements. Different industries and applications may demand distinct testing capabilities. For instance, power utility companies may need portable, rugged, and easy-to-use equipment to conduct on-site tests. While manufacturers may require higher precision lab-grade instruments for detailed analysis. Identifying your needs will narrow down your choices and ensure you select equipment that aligns with your unique use case.

Accuracy and Precision

The accuracy of testing results is of utmost importance in any testing process. Look for testing equipment designed to deliver high accuracy and precision levels. The accuracy of the equipment can directly impact the assessment of transformer health and performance. So, investing in high-quality equipment can be expensive upfront but will pay off in the long run.

Test Parameters and Capabilities

Transformer testing equipment is designed to measure a range of parameters such as turns ratio, winding resistance, insulation resistance, and more. Consider the specific tests required for your transformers and ensure that the chosen equipment can perform them accurately. Furthermore, some advanced models come with additional functionalities like dynamic resistance measurement, frequency response analysis, and partial discharge testing. Evaluating your test needs will help you choose equipment that covers all necessary aspects.

User-Friendliness and Ease of Operation

Complex testing procedures can be time-consuming and error-prone if the equipment is challenging to use. Look for user-friendly interfaces, intuitive controls, and clear instructions to simplify the testing process. Modern equipment often comes with graphical displays, touchscreen interfaces, and pre-programmed test sequences. All of these features make the testing procedure more efficient and accessible to operators of varying expertise.

Connectivity and Data Management

The ability to store and manage test data efficiently is vital for record-keeping, analysis, and future reference. Choose equipment that offers data storage options, data transfer capabilities (e.g., USB, Ethernet), and compatibility with data management software. This will simplify the organisation and retrieval of test results, facilitating data-driven decision-making. With better data management and connectivity, you can perform proactive preventative measures.

Safety Features

Transformer testing involves working with high voltages and currents, making safety a paramount concern. Ensure that the equipment complies with safety standards and incorporates features like interlocks, overload protection, and insulation integrity checks to safeguard operators and the equipment itself.

Certificate Photo

Factory Photo

FAQ

Q: What is the purpose of a transformer?

A: A transformer is a special machine used to change DC voltage from one level to another. It can be considered as an alternating current to a direct current converter. The transformer converts electrical energy into another form and changes AC’s voltage levels into some other levels of AC.

Q: What is the purpose of transformer testing?

A: To check if the main parts/components of electrical transformers are working correctly. To check the functioning of the whole transformer. To reduce the risk of failure of working. To confirm the specifications and performance of the transformer.

Q: What are the symptoms of a bad transformer?

A: Symptoms of power quality issues include vibration, excessive buzzing or humming and overheating. Technicians should occasionally check the power of transformers that supply nonlinear loads, such as variable frequency drives (VFDs) or switching power supplies.

Q: How often should a transformer be tested?

A: It is suggested to perform annual transformer maintenance in order to avoid potential problems, going no more than 3 years without thorough testing. Annual testing is a proven best practice and is the industry accepted standard.

Q: How do you test if a transformer is working?

A: The three primary tests used to determine the condition of a transformer are the open-circuit test, short-circuit test, and measurements of winding resistance.

Q: What is the most common cause of transformer damage?

A: The most common cause of failure of transformer is insulation failure; it deteriorates due to heat, oxidation, acidity and moisture. Line surges such as switching surges, voltage spikes, line faults and distribution abnormalities.

Q: What happens when a transformer is bad?

A: If your transformer is bad, you will have a tripped circuit breaker. It tips to prevent a voltage surge which can fry various parts inside the HVAC system resulting in a major breakdown of the equipment. Similarly, a transformer with clear burn marks or a bulged exterior is also a sign of a bad transformer.

Q: What are the symptoms of a bad transformer?

A: Symptoms of power quality issues include vibration, excessive buzzing or humming and overheating. Technicians should occasionally check the power of transformers that supply nonlinear loads, such as variable frequency drives (VFDs) or switching power supplies.

Q: What is current transformer testing called?

A: Polarity Test. The CT polarity is considered correct when the directions for the primary and secondary current oppose each other. Observing that correct polarity is important when first installing a CT, and the polarity test is often done at the same time as the ratio test using most current transformer instruments.

Q: What are the four basic types of transformer tests?

Below are four types of tests that should be done on power transformers to guarantee their suitability and efficiency.

(1)Turns Ratio Testing.

(2)Power Factor Testing.

(3)Insulation Resistance Testing.

(4)Resistance Testing.

Q: What are the two type of transformer test?

A: These tests include: Winding Resistance Test: Measures the resistance of transformer windings to calculate I2R losses. This test is essential for evaluating efficiency. Transformer Vector Group Test: Determines the arrangement of primary and secondary windings for correct phasing and voltage levels.

Q: What is the most common cause of transformer failure?

A: The most common causes of transformer failure include overloading, deterioration, power surges and moisture. Many of these failures occur within the transformer winding insulation and often times can be detected early by conducting rigorous visual, mechanical, and electrical inspections throughout its service life.

Q: How many years does a transformer last?

A: Between 25 and 40 years. The life of a power transformer mainly depends on the condition of the paper-oil insulation system. Manufacturers often define the expected life of power transformers to be between 25 and 40 years.

Q: How do you check if a transformer is working properly?

A: This can be done by measuring the voltage across the transformer’s terminals with a voltmeter. Another way to test for transformer failure is to measure the current flowing through the transformer while it is turned on. This can be done by measuring the amperage with an ammeter.

Q: What is the most important test in transformer?

A: Excitation current measurement is the most sensitive diagnostic electrical test available to transformer engineers for detecting not only core faults ,but also interturn faults in winding ,wrong connections of winding/tap changer ,displacements in core /winding during transport etc.

Q: How long does it take for power company to fix transformer?

A: Pole transformers can be replaced in a day, but some larger substation transformers might take several days to just put out the fire and months to replace.

Q: Is it easy to replace a transformer?

Q: What is the common problem of the transformer?

A: Overloading of transformers is a frequent issue in the electrical distribution system, posing a serious risk to their functionality and longevity. It occurs when a transformer is subjected to a load that exceeds its rated capacity, leading to overheating, insulation degradation, and potential failures.

Q: What damages a transformer?

A: Overloading causes overheating, and eventually, thermal degradation which will reduce the effectiveness of the winding insulation. Moisture – Moisture in a liquid-filled transformer can cause issues that result in irreversible damage to the insulation.

Q: How common are transformer failures?

A: During the constant rate period, the failure rate is about 0.0002 failures/year per transformer. Then, at about age 20~25 years, the failure rate begins to climb, reaching 0.01 at age 40, 0.025 at age 50, and over 0.05 at age 60.