Partial discharge testing

RuiDu Mechanical: Your Reliable Partial Discharge Tester Supplier!

RuiDu Mechanical and Electrical (Shanghai) Co., Ltd. is a leading global power testing equipment manufacturer and system solution provider. Our company was established in 2014. Our main products are substation transformers, high-voltage switches, transformers, lightning arresters, batteries, cable faults, relay protection, insulation withstand voltage, transformer oil injection equipment, etc. Our factory covering an area of more than 50,000 square meters, 6 product production lines and more than 200 employees, selling the products to more than 120 countries and regions. In addition, we support high-volume production, calibrate and test instruments at the point of sale, providing repair instructions for these products.

Rich Experienced

Our team has more than 10 years of experience in the industry, providing customers with compliant, high-quality equipment, and developing friendly cooperation with partners such as Kenya Power, UETCL, TCN, EVN, PLN, NGCP, CFE.

Wide Product Range

Our broad product offering includes digital multimeters, power analyzers, thermal imaging cameras, insulation resistance testers, accessories and integrated test tools. These test devices can be easily integrated into a variety of electrical and electromechanical systems.

Guaranteed Quality

Our production workshops are professionally assessed, developed and validated, equipped with a range of analytical instruments and all products have international ISO 9000 series, IEC and CE certifications.

Customized Service

According to your usage needs, our team is online 24/7 to provide you with detailed consultation and after-sales service, and provide OEM and ODM customized products.

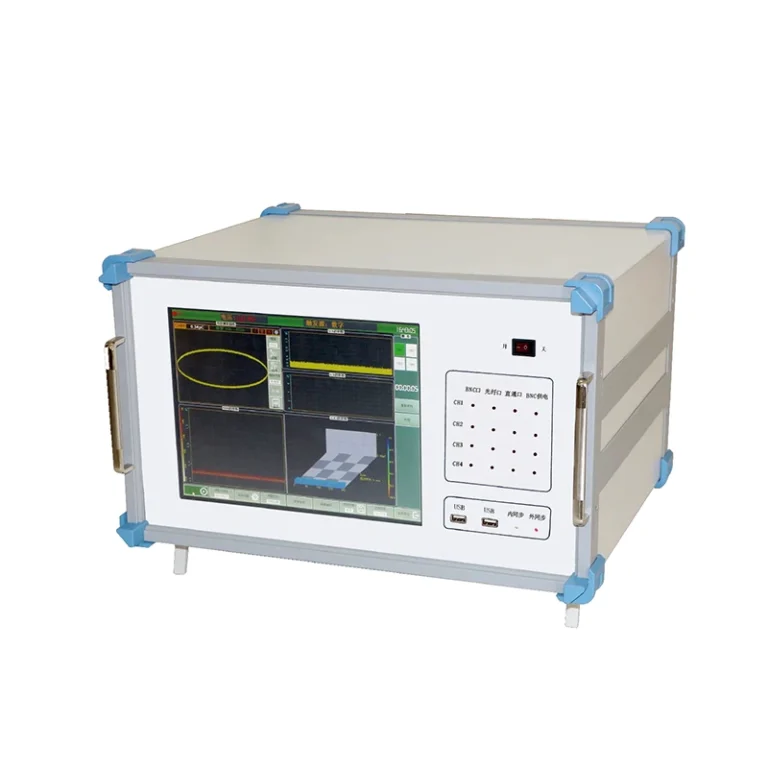

What is Partial Discharge Tester?

Partial discharges are “localized electrical discharges that only partially bridge the insulation between conductors.” It is a consequence of local electrical stress concentrations either inside the insulation (internal PD) or on the insulation’s surface (surface PD). Partial discharge testers, also known as PD testing machines, are increasingly utilized to evaluate the ability of the insulation barrier to withstand a repetitive peak voltage (Urp) applied over the lifetime of the component and to define a component voltage rating. Various methods are used to detect PD, including the detection of sound, light and radio frequency (RF) signals, alternating current (AC) hipot test.

Features of Partial Discharge Tester

Precise Measurement

Our partial discharge detector is equipped with AC withstand voltage testing and partial discharge detection functions. It is equipped with two ranges of 200pC and 2000pC, and can measure 1pC to 2000pC, with an optimal resolution of 0.1pC.

Easy to Integrate

These detectors are compact, feature synchronized voltage output capabilities to prevent high voltage differences between adjacent ends, and can be easily integrated into production lines or automated processes to optimize space.

Clear Data

They are equipped with HD display screen, and the results are displayed visually on the screen after measurement, helping to evaluate and analyze micro-discharge phenomena in highly insulating objects.

Run Smoothly

These testing equipment have a flashover detection function, which detects flashover by monitoring the change rate of test voltage or leakage current, which can avoid the occurrence of carbonized conductive paths or damage in the insulation layer of cables or other conductors.

Types of Partial Discharge

01/ Corona Discharge

This common form of partial discharge occurs when discharge is directly into the air emanating from the sharp surface of the conductor. (This is what causes the sound and radio frequency emissions.) From a damage or safety perspective, corona isn’t normally concerning.

02/ Arcing Discharge

Arcing discharge is a prolonged electrical discharge produced by the electrical breakdown of a gas. Plasma is produced when current flows through air, or any other normally non-conductive medium.

03/ Surface Discharge

When discharge travels along the surface of insulation, this is called surface discharge—or surface tracking. It can be one of the most destructive types of partial discharge. Contamination and weather of the insulator surface are the two most common causes of surface discharge. In medium- and high-voltage equipment, this type of discharge occurs when insulation breaks down, usually due to high humidity or poor maintenance. Moisture intrusion is also a common cause of surface discharge.

04/ Void (internal) Discharge

This is most often caused by a defect in the solid insulation of cables, bushings, GIS junction insulation, and such. Void discharge is highly destructive to insulation and will typically continue to expand until they cause complete failure.

05/ Floating Electrode / Floating Potential

Occurs when there is an ungrounded conductor within the electric field between conductor and ground (or between phases). This is the most common type of PD. Generally: UHF Antenna, TEV Sensor and HFCT are useful for detection of this type of PD.

06/ Particle Discharge / Floating Particle

Conductive particles can contaminate fluid dielectric, such as oil or SF6 gas. Particle PD is most common in SF6 gas compartments. UHF sensors are preferable for this type of PD. Therefore, analysis is done in an ultrasonic pulse timing mode.

How Does PD Affect Cable System?

●The vast majority of partial discharge does not occur all the time, but rather when the voltage of the cable system exceeds the “turn on” voltage of the PD site (referred to as the PD Inception Voltage, or PDIV).

●Surges in the power cable system (caused by switching, lightning strikes, etc…) can cause the cable voltage to momentarily exceed PDIV, leading to a burst of PD activity and erosion of the cable or accessory insulation.

●PD activity will continue until the cable voltage drops below the “turn off” voltage of the PD site (referred to as the PD Extinction Voltage, or PDEV).

●Every occurrence of PD activity will degrade the site further, causing the PDIV and PDEV to decrease.

●Once the PDEV drops below the normal operating voltage of the cable system, the PD activity and the associated insulation erosion will continue indefinitely (unless the cable is disconnected from power).

●From this point forward, a cable system failure will most likely occur in a short period of time.

Types of Partial Discharge Tester

Offline Partial Discharge Test Device

Offline PD testing is performed with the equipment taken out of service and energised with a test voltage source (Hipot). The PD detection equipment is coupled to the Device Under Test (DUT) and has the advantage of being able to analyse the DUT at different stress levels. An offline partial discharge testing device involves disconnecting a circuit and then testing it while powered by a low-frequency test set. This allows the user to measure the cable system’s response to a specific stress level.

Permanently Mounted Sensors

Permanently mounted sensors are used to monitor corrosion. Permanently mounted sensors have cabling that leads from an inaccessible area to a junction box or cable termination box. They can also be used for partial discharge (PD) testing, which is important for the health of electrical assets.

Ultrasound Partial Discharge Tester

An ultrasonic contact probe is a device that can detect and locate partial discharges in fluid dielectrics. These dielectrics include oil and SF6 gas compartments. This is sometimes called “in-tank” testing. The PD emissions produce high frequency sounds that Ultrasound can detect and translate into audible ranges that can be heard through headphones.

PD Surveyor

A PD Surveyor is a handheld device that can detect partial discharge (PD) activity in medium voltage (MV) power cables. PD surveys can help organizations assess the quality of their system’s insulation and the impact on the health of their equipment. Typically only 5 to 10 percent of medium and high voltage assets will have significant levels of PD activity.

PD Scan

The PD Scan is an on-line partial discharge (PD) handheld scanner for detecting defects in medium and high voltage systems (MV and HV). PD is an indicator of emerging defects in insulation. It occurs when a small area of insulation in a high voltage environment breaks down due to electrical stress. Such defects not only require costly repairs, but also can lead to failures of entire network sections with corresponding consequences.

Available Testing Techniques of Partial Discharge

When detecting PD in MV/HV switchgear, bus ducts, cables, etc. it is much easier if we can do this live without interfering with supply. The most practical ways revolve around detecting different frequency signals. Using a combination of sensors ensures different types of PD can be readily identified.

Ultrasonic Methods

They are particularly effective at finding surface PD and corona PD. Acoustic emissions from PD activity are normally at a frequency too high for the human ear, i.e. ultrasonic. As the PD gets worse, the frequency sometimes decreases into the audible range. Using an airborne ultrasonic microphone is the most sensitive way to detect PD where there is an air path between the source and the microphone. Contact ultrasonic sensors can be used for sealed chambers.

PD Generates Transient Earth Voltages (TEV) –high frequency electromagnetic pulses.

TEV methods are particularly effective at finding internal PD. TEV signals travel across the inside surfaces of switchgear, escaping to the outside through openings in the metalwork e.g. gaskets. PD activity can be detected by placing a TEV sensor on the outside of the switchgear to measure these pulses.

UHF

It is ideal as a non-contact detection method for electromagnetic PD signals in open terminal switchyards, cable systems and distribution networks.

HFCT/RFCT Online Cable Testing

It can be done using high frequency current transformers (HFCT) or radio frequency current transformers (RFCT) based test systems that measure PD pulses that work their way onto an external cable ground. The advantage is that the cable can be kept in service and the test is quick and very few resources as a offline test would require.

How to Avoid Partial Discharge?

Key Roles For Design, Materials and Workmanship

Under normal operating conditions the insulation system will withstand PD throughout the equipment’s lifetime, and require routine periodic maintenance to manage PD. The insulation system, together with the quality of the design and workmanship, and selection of materials, play a central part in determining the level and impact of PD activity. As a result, the first step in tackling PD has to be taken well before the motor or generator is ordered.

Detecting and Measuring PD

In most cases it does make sense to measure PD, because it can reveal problems that would be difficult to detect otherwise. However, individual PD measurements are notoriously difficult to evaluate. A better option is to take periodic measurements, starting with a fingerprint measurement on the new winding, in order to obtain trend data.

Some plants prefer a more comprehensive approach vs. measuring PD alone. We measure PD, along with a number of other measurements in order to evaluate the remaining lifetime of the stator winding insulation. In addition, it’s a good idea to carry out visual inspections.

Issues that need to be decided are: Will PD be measured, and if so will it be done by plant personnel or outside contractors? What method will be used? And will additional assessments and inspections be performed?

These questions need to be answered at an early stage because PD measurement requires investment and may also require special hardware.

Stipulate Low PD Levels

For plants that are reluctant to invest in PD monitoring, an alternative is an extended-lifetime motor or generator. While dependable manufacturers ensure that their standard products are designed and built to withstand PD, enhanced products like motors and generators from us will provide an extra ‘safety margin’ and longer service lifetimes.

By contrast, we don’t recommend specifying low PD levels during the procurement process. This inevitably leads to higher costs, and often doesn’t produce the desired results. This is because there’s no direct correlation between PD magnitude and insulation lifetime. For a particular motor or generator it may well be that electrical stress is not the dominant factor behind insulation aging.

Certificate Photo

Factory Photo

FAQ

Q: What is the purpose of partial discharge test?

A: As a result, partial discharge testing is increasingly utilized to evaluate the ability of the insulation barrier to withstand a repetitive peak voltage (Urp) applied over the lifetime of the component and to define a component voltage rating.

Q: Is partial discharge testing destructive?

A: It is a nondestructive test and does not use over voltages that could adversely affect the equipment. Online Partial Discharge Testing is relatively inexpensive compared to offline testing that requires interruption of service and production.

Q: What is a PD detector?

A: The PD Detector is highly sensitive to the ultrasonic emissions produced by tracking and enable the onset to be detected before insulation failure.

Q: What defects lead to partial discharge?

A: Anything that causes a localized increase in that stress can lead to PD activity: Voids in the insulation. Damage to the cable from the backfill. Protrusions such as nails, tacks, or other objects.

Q: What is the difference between tan delta and partial discharge test?

A: Using VLF voltage source, Tan Delta (TD) and Partial Discharge (PD) measurement can be carried out simultaneously. TD measurement is a nondestructive integral test to assess the overall cable condition, while PD measurement can be used to localize defects that generate electric discharge activities.

Q: How does partial discharge monitoring work?

A: Using an airborne ultrasonic microphone is the most sensitive way to detect PD where there is an air path between the source and the microphone. Contact ultrasonic sensors can be used for sealed chambers. -PD generates Transient Earth Voltages (TEV) – high frequency electromagnetic pulses.

Q: Is corona the same as partial discharge?

A: Like partial discharge, corona is an electrical discharge that does not fully bridge a dielectric, but corona describes only a very specific type of discharge–the ionization of gas surrounding a surface of high electric potential.

Q: How do you prevent partial discharge?

A: Selecting a reputable manufacturer with a strong record of quality and expertise is the best way to ensure you avoid issues with partial discharge. There’s an increasing trend for plants to stipulate low partial discharge (PD) when they specify high voltage motors and generators.

Q: How to do a partial discharge test?

A: Partial discharge cable testing involves applying a voltage conducive to partial discharge and then directly or indirectly measuring the discharge current pulses. Tan delta testing requires isolation from equipment not under test, and therefore, must be done off-line.

Q: What is the acceptable value of partial discharge?

A: Normally it is assumed that a partial discharge of less than 10 pC doesn’t lead to any harm in the insulation material. Teh partial discharge test is a so called “non-destructive” test. This means if there aren’t any high PD-levels, the test item won’t get harmed.

Q: What is the difference between a full discharge and a partial discharge?

A: Full discharge: Request to discharge security as AMP loan will be (or has been) repaid. Partial discharge: Request to release one of the securities on an AMP Loan where there are multiple properties held as security for the loan.

Q: Where does partial discharge occur?

A: PD can occur in a gaseous, liquid, or solid insulating medium. It often starts within gas voids, such as voids in solid epoxy insulation or bubbles in transformer oil. Protracted partial discharge can erode solid insulation and eventually lead to breakdown of insulation.

Q: What does partial discharge sound like?

A: Partial discharge or Tracking occurs where there is a low current pathway to ground across an insulator. There is a buildup and discharge of the voltage that produces “popping” sounds. The discharge peaks correspond to the “popping” sounds. They are not uniformly spaced in time.

Q: What is partial discharge at low voltage?

A: Partial discharges occur when the breakdown field strength of the dielectric is locally exceeded due to varying local field intensity or varying local voltage resistance, resulting in the partial breakdown of the insulation system.

Q: What is partial discharge test on high voltage cables?

A: Cable PD occurs from a small insulation defect. It causes a discharge across part, but not all, of the insulation between conductors. The purpose of partial discharge testing of MV/HV cables is to find the discharge before it leads to flashover and catastrophic failure.

Q: What is the minimum voltage to discharge a battery?

A: The truth is that any lead acid battery, be it a Gel Cell, AGM or flooded batteries such as DCBs, should be cut-off at 11.6 volts. Not doing so increases the risk of damage to the battery and if taken down deep enough into the batteries charge, will ruin the battery.

Q: Which three items are emitted from a partial discharge site?

A: Partial discharge emits energy in a variety of forms including electromagnetic, gas and acoustic, allowing several ways to detect it when present.

Q: Why is partial discharge bad?

A: Partial discharge might be small in size, but it does cause insulation to deteriorate over time, which will ultimately lead to failure. If left unchecked, insulation failure can result not only in loss of supply to processes or customers but can also endanger staff.

Q: Why is partial discharge test important?

A: These predictive diagnostics help companies to prioritize capital and MRO investments before an unexpected outage occurs. Partial Discharge Testing results can help predict future performance and reliability of critical assets, including: Cables, splices, and terminations. Power transformers and bushings.