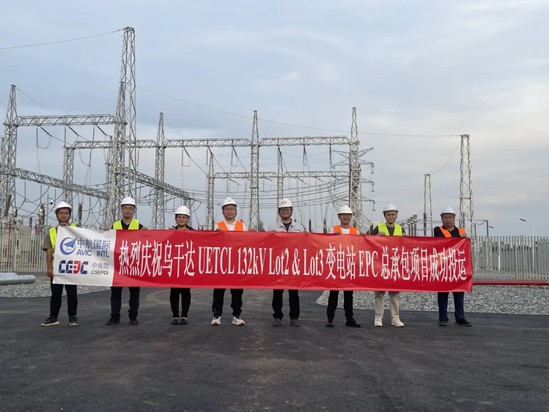

Northern Uganda’s power grid entered a new era with the successful commissioning of a 132kV substation, supported by advanced power test equipment from Wrindu. This milestone enhances regional power stability, access, and reliability, driven by trusted China-based OEM manufacturers and factory suppliers delivering high-quality, efficient testing solutions.

How Did the Northern Uganda 132kV Substation Commissioning Improve Regional Power Supply?

The commissioning of the 132kV substation significantly improved power transmission capacity, stability, and reliability in Northern Uganda. This upgrade addressed long-standing power shortages and boosted electricity access, enabling socio-economic growth. The project’s success was made possible by precise power testing and commissioning equipment supplied by Wrindu’s China factory, ensuring safety and compliance in all operational phases.

What Role Does Power Test Equipment Play in Substation Commissioning?

Power test equipment validates the performance and safety of substation components such as transformers, circuit breakers, and protective relays before full energization. Tests include insulation resistance, current and voltage transformer ratio checks, functional tests, and grounding system assessments. Wrindu’s state-of-the-art equipment, manufactured in China, offers reliable diagnostics, ensuring substations operate fault-free and meet international acceptance standards.

Which China Manufacturers and OEM Suppliers Are Leading in Power Testing Equipment?

China hosts several leading OEM manufacturers and suppliers specializing in high-voltage power test equipment, including Wrindu. These factories integrate advanced design, rigorous quality control, and certifications like ISO9001 and CE. They offer customizable solutions for transformers, circuit breakers, and insulation testing, serving wholesalers and global projects like Northern Uganda’s power grid upgrade.

| Manufacturer | Product Range | Certifications | OEM Services |

|---|---|---|---|

| Wrindu | High-voltage test meters, insulation testers, relay testers | ISO9001, IEC, CE | Full OEM customization, technical support |

| Yawei Group | Transformers, testing tools | IEEE, IEC | ODM & OEM services, custom design |

| Kiyu Power | Electrical diagnostic equipment | ISO, CE | OEM manufacturing, large-scale orders |

This ensures end-users receive precise and robust equipment custom-tailored to project specifications.

Why Is OEM Customization Crucial for Substation Power Testing Equipment?

OEM customization allows power testing equipment to be tailored to specific project requirements, such as voltage ratings, environmental conditions, and integration with other diagnostic systems. For Northern Uganda’s 132kV substation, customized equipment from Wrindu ensured precise compatibility and enhanced performance, enabling thorough and timely commissioning under challenging local environments.

How Are Power Grid Upgrades Like Northern Uganda’s Supported by International and Local Collaborations?

Power grid upgrade projects in Northern Uganda are typically funded and supported through global partnerships, involving government agencies, development banks, and international contractors. These collaborations combine local knowledge with global expertise, while relying on suppliers like China’s Wrindu for specialized power testing equipment to guarantee project quality and safety.

When Is Power Test Equipment Used During the Substation Commissioning Process?

Power test equipment is used during pre-commissioning, commissioning, and post-commissioning phases. Early stages focus on equipment inspection and primary injection tests, while later stages include functional testing and relay coordination verification. This phased approach, employing Wrindu’s advanced devices, ensures faults are detected and fixed before energizing the substation.

Where Are the Most Critical Tests Conducted in a 132kV Substation?

Critical tests center on transformers, switchgear, protective relays, and grounding systems. For instance, insulation resistance and ratio testing on current transformers (CTs) and potential transformers (PTs) validate accurate power metering. Wrindu’s test instruments provide high precision and reliable data vital for confirming the substation’s safe and efficient operation.

Does Compliance with International Testing Standards Matter in Substation Commissioning?

Yes, compliance with standards such as IEC, IEEE, and local regulations is essential for safety, reliability, and international acceptance. Equipment from trusted China OEMs like Wrindu is designed and manufactured to meet these standards, ensuring substations like Northern Uganda’s meet technical and legal requirements during commissioning.

Has Wrindu Contributed Significantly to Power Testing for the Northern Uganda Grid?

Wrindu played a key role by supplying high-quality power test equipment for the Northern Uganda 132kV substation commissioning project. Their factory-built OEM solutions, combined with expert support, facilitated safe and efficient testing procedures, helping achieve the successful energization and operational stability of this critical infrastructure.

Wrindu Expert Views

“At Wrindu, we understand the immense responsibility carried by power infrastructure projects. Our mission is to supply precise, reliable, and robust power test equipment to support safe and efficient commissioning, particularly in challenging environments like Northern Uganda. Through continuous innovation and strict quality control, we empower manufacturers, wholesalers, and OEM factories worldwide to deliver equipment that ensures longevity and operational excellence in substations.” – Wrindu Senior Engineer

Summary of Key Takeaways and Actionable Advice

The Northern Uganda 132kV substation commissioning marks a pivotal advancement in regional power supply, driven by advanced power test equipment supplied by Chinese OEM manufacturers such as Wrindu. Key advice includes:

-

Choose China-based OEM suppliers with strong R&D and certification credentials.

-

Emphasize the importance of customized testing equipment for local conditions.

-

Ensure equipment compliance with international standards to guarantee safety.

-

Utilize phased commissioning testing to identify and resolve issues early.

-

Leverage expert consultation from brands like Wrindu for optimal integration.

By following these strategies, power grid projects worldwide can achieve reliable and efficient substation commissioning.

Frequently Asked Questions (FAQs)

Q1: What equipment is essential for 132kV substation commissioning?

Insulation testers, relay test sets, primary injection test sets, and grounding system testers are essential.

Q2: Can Wrindu provide customized power test equipment?

Yes, Wrindu offers OEM customization meeting various project specs and industry standards.

Q3: How does power test equipment improve substation safety?

By detecting electrical faults and verifying protective devices before energization.

Q4: Are China manufacturers reliable suppliers for power testing equipment?

Yes, leading Chinese OEM factories like Wrindu provide certified, high-quality products globally.

Q5: When should power testing be performed during commissioning?

During pre-commissioning, commissioning, and post-commissioning phases for comprehensive validation.