OVERVIEW

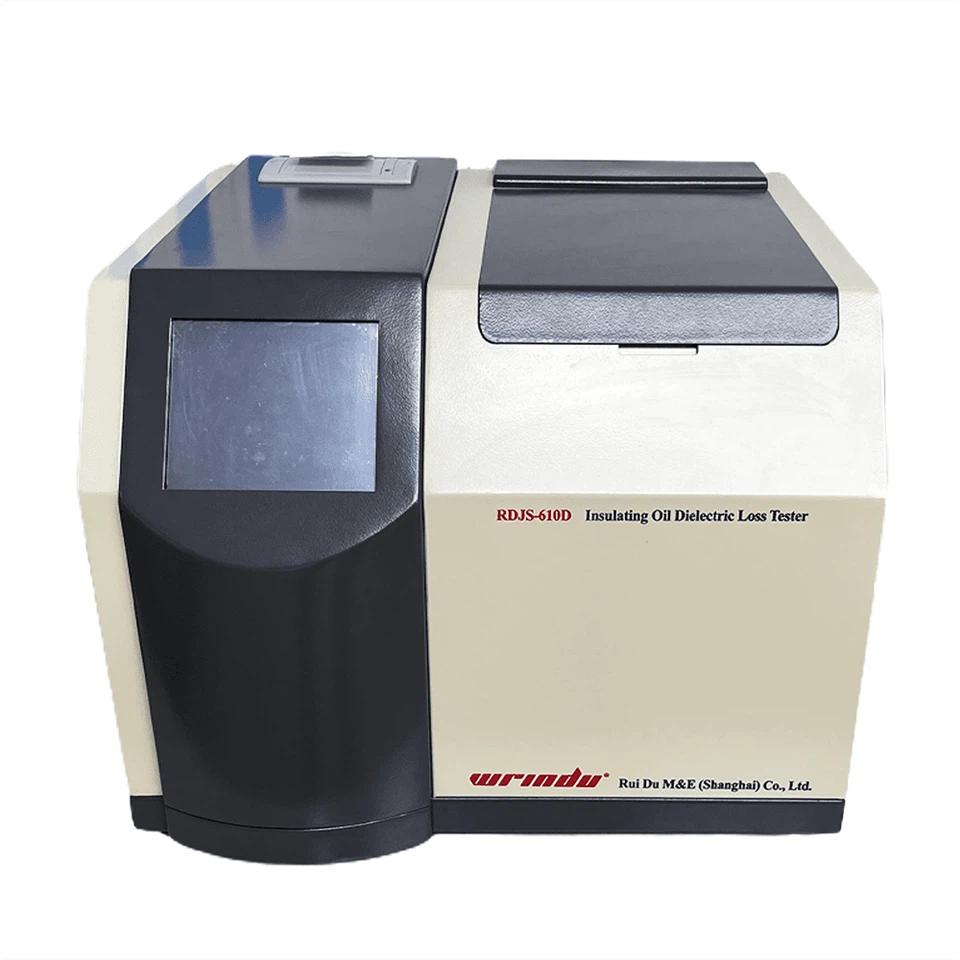

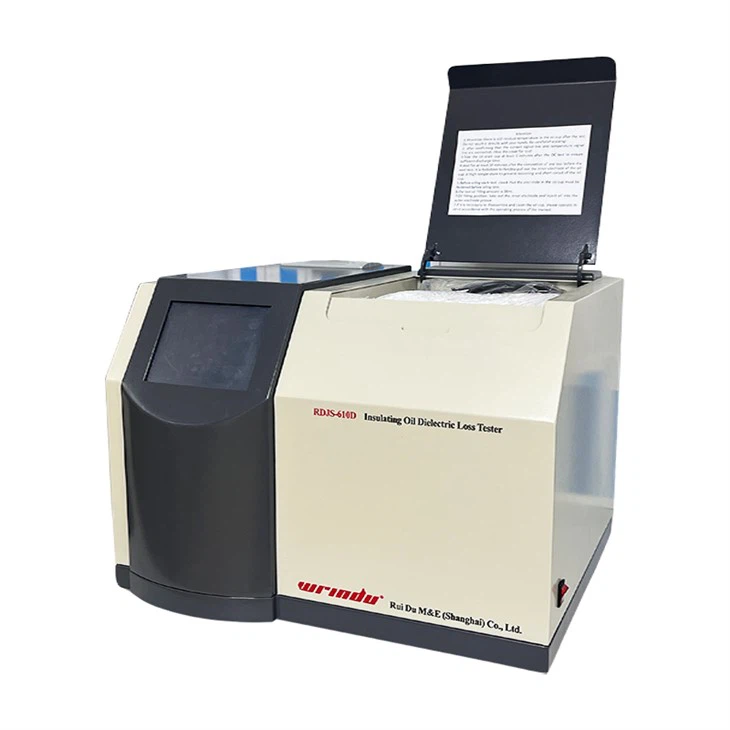

RDJS – 610D Insulating oil tan delta test set is specially designed for dielectric loss factor and DC resistivity measurement of liquid insulating media such as insulating oil. It adopts an integrated compact structure, and its core components, such as the dielectric loss oil cup, temperature controller, temperature sensor, dielectric loss test bridge, AC test power supply, standard capacitor, high resistance meter, and DC high voltage source, are highly integrated. The oil tan delta test set uses advanced all-digital technology to achieve full-process intelligent automatic measurement. It has a large, high-resolution, color LCD screen and operates with a menu-based interactive interface. Clear text prompts accompany each operation step. Test data can be automatically stored and supports convenient printouts. Even if the operator has not received professional and in-depth training, he can skillfully use the instrument to perform measurement work with a simple and precise operation process.

CHARACTERISTIC

1. This instrument adopts medium-frequency induction heating technology and a PID temperature control algorithm. This heating method has the advantages of being non-contact, uniform, rapid, and convenient for temperature control, ensuring that the temperature is strictly controlled within the set range with minimal error.

2. The built-in SF6 gas-filled three-electrode standard capacitor maintains stable capacitance and dielectric loss unaffected by ambient temperature and humidity. This ensures that the instrument can still maintain high accuracy after long-term use.

3. Equipped with a comprehensive protection mechanism, it can quickly disconnect the high-voltage power supply and issue a warning when an overvoltage, overcurrent, or high-voltage short circuit occurs. At the same time, when the temperature sensor fails or is not connected, the instrument will also alarm in time.

4. A temperature-limiting relay is installed in the medium-frequency induction heating furnace. When the temperature exceeds 120℃, the relay will automatically disconnect the heating to ensure safe use.

5. The test parameter setting is simple and intuitive, the temperature adjustable range is 40℃ to 120℃, the AC voltage is 200V to 2200V, and the DC voltage is 0V to 500V, which can flexibly meet different test needs.

6. The oil tan delta test set has a large-screen TFT color touch LCD. The display is clear, and the operation is convenient. The instrument can automatically perform tests through simple settings and store and print results.

7. The built-in real-time clock can synchronously save, display, and print test dates and times, making it easy to record and manage.

8. The empty electrode cup calibration function measures the capacitance and dielectric loss factor of the empty electrode cup and judges its cleanliness and assembly status. The calibration data is automatically saved to support the accurate calculation of relative permittivity and DC resistivity.

9. Based on the RAM9 platform, it ensures high accuracy and fast response, providing users with an efficient and reliable testing experience.

For more information about oil testing equipment, please click More.

To request the latest quotes, please click Contact Us.

FAQ

Q: What is the tan delta of oil?

A: Tan Delta, also known as the Loss Angle, Dielectric Dissipation Factor (DDF), or Power Factor (PF), is a dielectric test used to evaluate the quality of insulating oil. This test measures the energy loss in the oil when subjected to an alternating electric field. It is typically conducted at two different temperatures to assess the oil’s performance and insulation properties.

Q: What is the acceptable value of the tan delta test?

A: A Tan Delta value of less than 0.7% is acceptable. This test is performed periodically, and the current results are compared with previous ones. Over time, the Tan Delta value may degrade due to various factors. Below is an example of a Tan Delta test report conducted on a power transformer.

Q: What is the oil tan delta test?

A: The oil tan delta test is a reliable method for assessing transformer oil quality. It measures the tangent of the dielectric loss angle (tan delta), with higher values indicating reduced oil insulation performance.