OVERVIEW

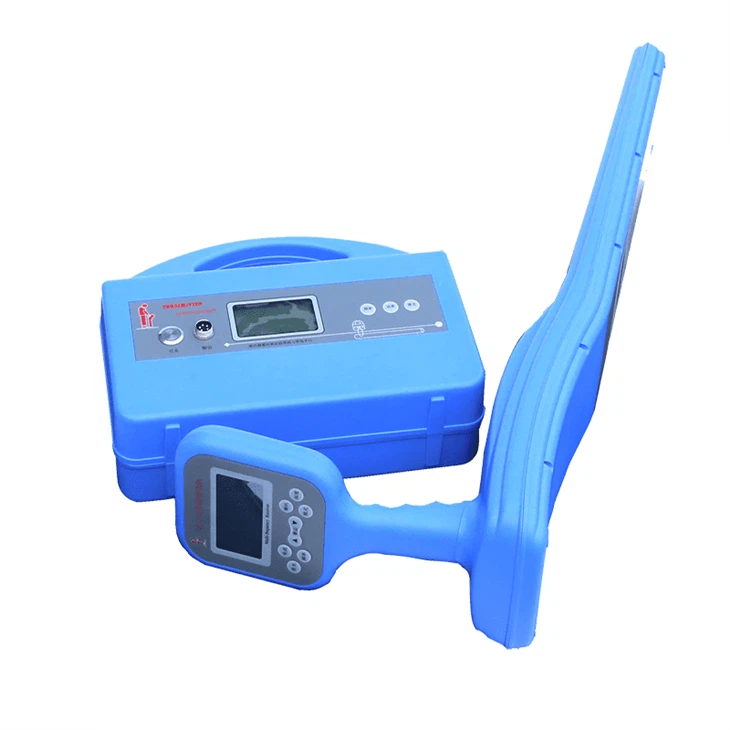

Our RDCD-Ⅱ Trolley – type Cable Fault Locator System is the result of years of continuous improvement and innovation.Employing modern power electronic technology, it stands as a leading product in the field of cable fault testing instruments globally. It is mainly used to measure the distance, find the path, and locate main insulation faults in power cables with voltages of 35kV and below, Moreover, it can measure low resistance, short circuits, open-circuit faults in various cross-sectional high-frequency coaxial cables, telephone cables, streetlight cables, and buried wires. Additionally, This Cable Fault Locator System Trolley Type detects high-resistance leakage and high-resistance flashover faults. The system comprises four units: RDCD-Ⅱ/502 Cable Fault Pre-locator, RDCD-Ⅱ/535T Cable Test High Voltage Signal Generator, RDCD-Ⅱ/503D Cable Fault Locator, and RDCD-Ⅱ/507 Underground Pipeline Detector.

CHARACTERISTIC

- It is controlled by a 12 – inch industrial – grade computer and supports touch operation;

- It runs on the Windows operating system and has a powerful cable management system that can generate test reports automatically;

- Features distance and speed measurement functions;

- Automatic continuous sampling, never missing any discharge waveform;

- Supports multiple testing methods: low-voltage pulse method, high-voltage flashover method, multi-pulse method;

- Massive storage of test waveforms for easy retrieval and viewing in the specified order;

- Simultaneously displays fault point waveform and full-length open-circuit waveform, improving accuracy in fault distance determination;

- Built-in polymer lithium battery can work continuously for over 4 hours;

- Automatically displays eight pulse transmissions and fault reflection signals, eliminating testing blind spots, and simplifying fault characteristic waveforms.

FAQ

Q: How do you locate a cable fault?

A: Fault location in a cable typically begins with the testing of the cable for faults. During the testing process, flashovers are generated at weak points in the cable, allowing for precise localization of the fault.

Q: How do you find a fault in an electrical cable?

A: Multiple cable fault detection methods exist, such as time domain reflectometry, bridge methods, and surge methods. The thumper tester, also known as the underground cable fault locator, is recognized as the most efficient tool for this purpose. By generating high-energy pulses and analyzing reflections, it provides precise and effective fault localization.

Q: What tool locates cable faults?

A: A cable fault locator, also known as a thumper tester, is the primary tool for locating cable faults. It operates by generating high-energy pulses to identify faults through reflected signals, offering efficient and precise fault localization.

Q: How do we test if a cable is faulty?

A:Testing for cable faults involves a comprehensive approach:

1. Visual Inspection: Check for visible damage.

2. Insulation Resistance Test: Use a megohmmeter to measure insulation resistance.

3. Continuity Test: Verify electrical continuity.

4. TDR: Estimate fault distances with Time Domain Reflectometry.

5. Fault Locator: Apply high-voltage surges for pinpointing faults.

6. Sheath Testing: Identify sheath faults if applicable.

7. Thermal Imaging: Detect temperature anomalies.

8. Acoustic Methods: Listen for fault-associated sounds.

9. Excitation Test: Assess the cable’s electrical response.

10. Voltage Drop Test: Measure under load conditions.

Tailor tests to cable-type suspected faults, and adhere to safety standards throughout.

APPLICATION