OVERVIEW

- In the whole life cycle of the transformer, the winding resistance test is an indispensable and key item, from the semi-finished and finished product factory inspection in the manufacturing process to the installation and handover stage and then to the daily preventive test in the power sector. It is like an accurate “medical checkup doctor” who can keenly detect the potential hidden dangers of transformer coils in terms of whether the material selection is proper, whether the welding is firm, whether the connection parts are loose, whether there are manufacturing defects such as missing strands or broken wires and the potential hidden dangers that are nourished after running for some time.

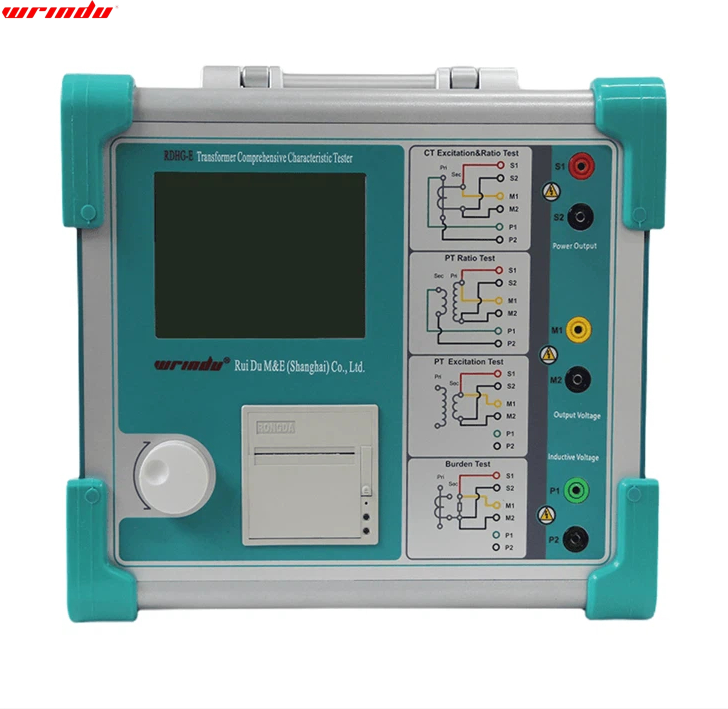

- The newly developed dual-channel winding resistance meter was born to meet the urgent need for fast and accurate measurement of transformer DC resistance. This instrument integrates cutting-edge power supply technology, combining a compact and lightweight body with super strong output current, completely subverting the bulky image of traditional instruments. It is controlled by an advanced microcontroller system, which automatically starts the self-check process to ensure that the instrument’s status is flawless, that a large amount of data can be quickly processed, and that the measurement results are presented intuitively. Moreover, it has an automatic discharge function and eye-catching discharge indication mark, guaranteeing operation safety. Ultra-high testing accuracy and minimalist operation process so that the measurement of transformer direct resistance becomes efficient and quick.

- Among them, the dual-channel winding resistance meter is tailor-made for the temperature rise measurement of three-core, five-pillar large transformers. It has lightning-fast charging and measuring speeds, performs excellently in temperature rise tests that compete for seconds, and can fully meet the stringent time requirements. Dual-channel synchronous measurement, real-time accurate sampling, convenient printout function, easy to overcome the temperature rise test in heavy difficulties, for power workers to provide strong technical support.

CHARACTERISTIC

- 1. The instrument supports high current output and high voltage working modes.

- 2. Dual-channel design can synchronize the detection of two resistance values.

- 3. Built-in comprehensive protection mechanism with excellent stability and reliability.

- 4. Horizontal structure, especially suitable for on-site use in transformer factories.

- 5. The dual-channel winding resistance meter provides an audio discharge alarm and clear discharge indication function, significantly reducing the risk of operational errors.

FAQ

Q: How do you measure the DC resistance test?

A: The transformer winding resistance tester functions by applying DC (I) to the winding, measuring DC voltage (V) at both ends of the device under test, and then calculating the winding resistance using Ohm’s Law (R = V/I).

Q: How do you find the DC resistance of a transformer?

A: Measuring transformer winding resistance is accomplished through the current-voltage method. The resistance value is easily determined by applying a test current to the winding and measuring the resulting voltage drop (Rx = V/I). This approach ensures an accurate assessment of the winding’s electrical characteristics.

Q: How do you find the internal resistance of a DC source?

A: To find the internal resistance (r) of a DC source:

1. Isolate the source.

2. Connect an external resistor (R)).

3. Measure voltage (V)) across (R).

4. Measure current (I).

5. Apply Ohm’s Law: r = V/I- R).