OVERVIEW

During the production of semi-finished and finished power transformers, and before commissioning a newly installed transformer, a turn ratio or voltage ratio test is performed on the transformer in operation. This test checks the accuracy of the turn ratio, the condition of the on-load tap-changer, the presence of turn-to-turn short circuits, and whether the transformer is ready for parallel operation. Conventional ratio bridge testing has shortcomings, such as unintuitive readings, complex conversions, and phase-by-phase measurements. For these problems, our Wrindu transformer ratio meter provides an innovative solution with simple and intuitive operation. The instrument adopts a three-phase precision inverter power supply, with fast testing speed and high accuracy, which significantly improves the testing efficiency and accuracy, providing an essential guarantee for transformer production and operation.

CHARACTERISTIC

- 1. The instrument integrates a three-phase precision inverter power supply inside, which effectively filters the harmonic interference in the utility voltage and ensures the high accuracy of the measurement results. Even if a generator power supply is used, measurement accuracy will not be affected.

- 2. By designing a three-phase output voltage, the transformer ratio tester improves the testing speed, accurately measures the angle between phases, and automatically recognizes the wiring group from 0 to 11. For rectifier transformers with multiple windings on the low-voltage side, the measurement of ratio and 7.5° angular deviation can be completed without removing the wires, greatly simplifying the operation process.

- 3. It applies to many types of transformers, including but not limited to Z-type transformers, rectifier transformers, grounded transformers, furnace transformers, phase-shifting transformers, balanced transformers, Scott transformers and inverse Scott transformers, etc., which can widely satisfy the needs of different application scenarios.

- 4. To ensure safety and stability, the instrument has several built-in protection functions, such as high and low-voltage reverse connection protection, transformer turn-to-turn short circuit protection, tap changer tap-in-place protection, and output short-circuit protection.

- 5. The instrument can automatically complete the ratio, error, and tap changer position measurements by entering the transformer’s rated parameters. Especially for asymmetrical tap changers, it can also accurately determine their position and support, measuring up to 99 tap positions, providing extremely high accuracy.

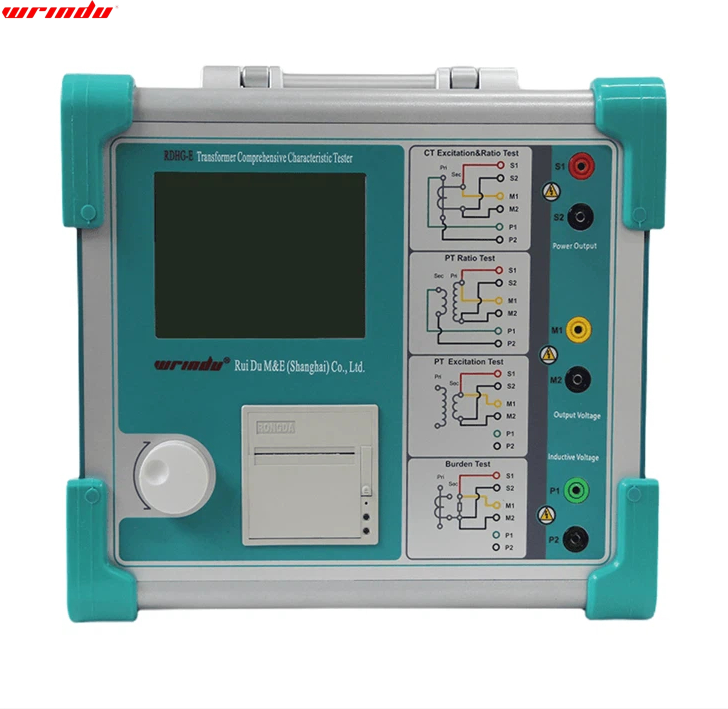

- 6. The transformer ratio meter has a 7-inch high-definition color touch screen with a modular interface design and clear menu prompts for each operation step. Users only need to follow the screen instructions to complete all operations efficiently.

- 7. Regarding data management, it supports printouts and a U disk interface and provides an RS232 interface option, which is convenient for managing paperless data.

- 8. Considering the fieldwork needs, the device adopts a multi-functional engineering plastic case that is cold and temperature-resistant, sealed and waterproof, and drops and shockproof, ensuring stable work in various environments.

- 9. To improve the user experience, users can download a unique app to control the instrument’s operation. Test data can be stored and uploaded to the cloud for easy access and management anytime.

For more information about transformer test equipment, click More.

To request the latest quotes, please click Contact Us.

FAQ

Q: Why should the transformer turns ratio be measured?

A: Measuring the turns ratioof a transformer is crucial. It helps evaluate performance, identify winding faults, ensure quality control, promote preventive maintenance, and adhere to international standards. This essential diagnostic tool maintains the transformer’s reliability and safety.

Q: What is the turn ratio of a 3-phase transformer?

A: The turns ratio of a 3-phase transformer, denoted as a: bor a/b, reflects the relationship between the turns in its primary and secondary windings. This ratio determines how voltage transforms across each phase’s primary and secondary sides, shaping the transformer’s electrical characteristics and performance. Tailoring the transformer’s behavior to meet specific voltage requirements and ensure efficient power transmission in diverse applications is essential.

Q: What is a transformer with a turn ratio of less than 1?

A: A transformer with a turn ratio of less than 1 is commonly called a step-down transformer. In this configuration, the number of turns in the primary winding exceeds that in the secondary winding, reducing the voltage from the primary to the secondary side. This design is frequently utilized to adapt electrical energy for various applications.